CHASSIS

3-22

ECA4D3F005

Excessive chain slack will overload the

engine and other vital parts; keep the slack

within the specified limits.

e. If the chain slack cannot be adjusted,

replace the sprockets and drive chain as a

set.

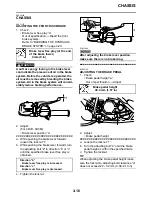

f.

Tighten the rear axle pinch bolts.

TIP

• Tighten the rear axle pinch bolts in the

proper sequence as shown.

• The chain should be cleaned and lubricated

after every use of the vehicle.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS21440

LUBRICATING THE DRIVE CHAIN

The drive chain consists of many interacting

parts. If the drive chain is not maintained prop-

erly, it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rub-

ber O-rings between each side plate. Steam

cleaning, high-pressure washing, certain sol-

vents, and the use of a coarse brush can dam-

age these O-rings. Therefore, use only

kerosene to clean the drive chain. Wipe the

drive chain dry and thoroughly lubricate it with

engine oil or chain lubricant that is suitable for

O-ring chains. Do not use any other lubricants

on the drive chain since they may contain sol-

vents that could damage the O-rings.

EAS29280

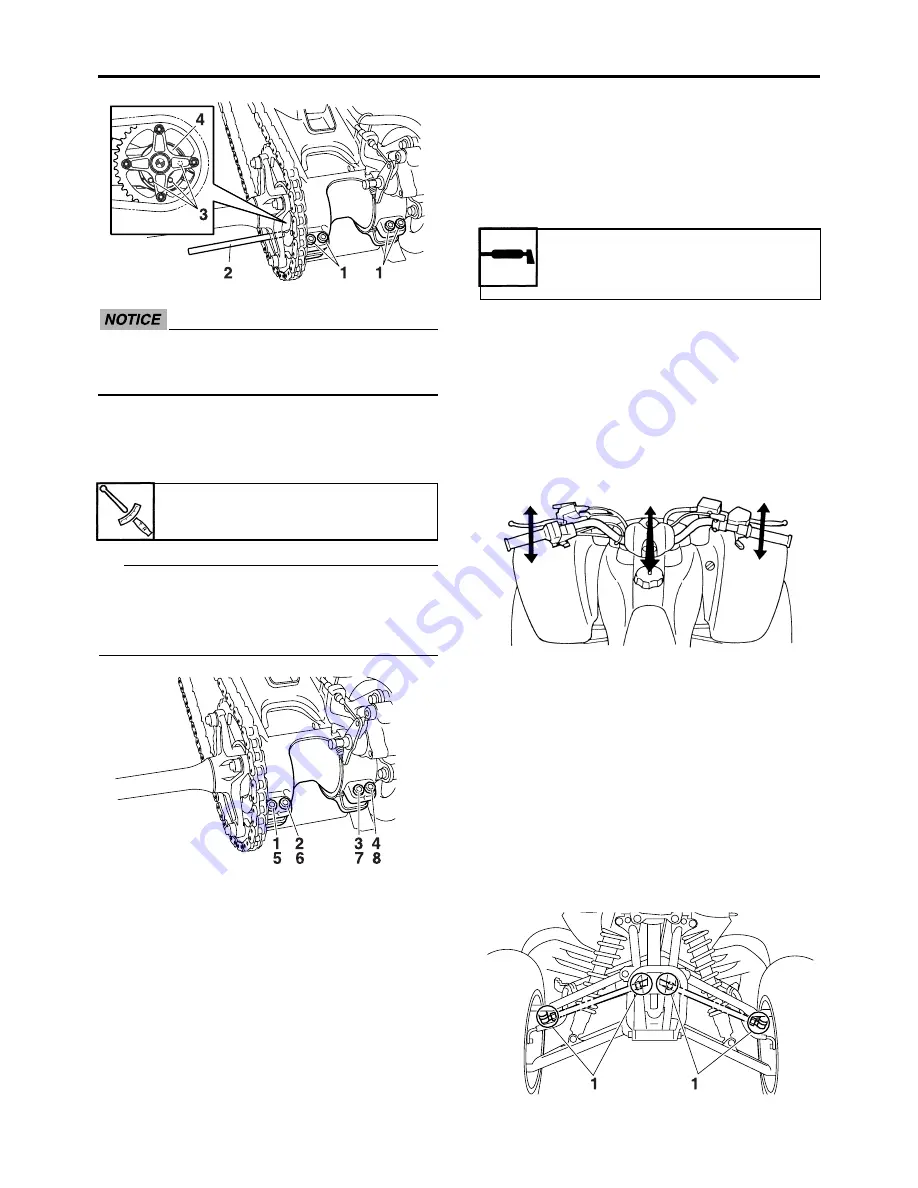

CHECKING THE STEERING SYSTEM

1. Place the vehicle on a level surface.

2. Check:

• Steering assembly bushings

Move the handlebar up and down, and

back and forth.

Excessive play

→

Replace the steering

stem bushings.

3. Check:

• Tie-rod ends “1”

Free play

→

Replace the tie-rod end.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the handlebar left until it stops.

b. Move the handlebar slightly to the right and

left.

c. Check for play in the tie-rod ends.

d. Turn the handlebar right until it stops.

e. Move the handlebar slightly to the left and

right.

f.

Check for play in the tie-rod ends.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Rear axle pinch bolt

21 Nm (2.1 m·kg, 15 ft·lb)

Recommended lubricant

Engine oil or chain lubricant

suitable for O-ring chains

Summary of Contents for 2009 YFM25RY

Page 1: ...SERVICE MANUAL YFM25RY YFM25RSEY YFM25RSE2Y 4D3 28197 11 LIT 11616 22 09 2009 ...

Page 8: ......

Page 39: ...LUBRICATION POINTS AND LUBRICANT TYPES 2 20 ...

Page 42: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 23 EAS20410 LUBRICATION DIAGRAMS ...

Page 44: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 25 ...

Page 46: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 ...

Page 47: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 28 1 Oil cooler 2 Oil hose 1 3 Oil hose 2 ...

Page 48: ...CABLE ROUTING 2 29 EAS20430 CABLE ROUTING ...

Page 50: ...CABLE ROUTING 2 31 ...

Page 52: ...CABLE ROUTING 2 33 ...

Page 54: ...CABLE ROUTING 2 35 ...

Page 56: ...CABLE ROUTING 2 37 ...

Page 58: ...CABLE ROUTING 2 39 ...

Page 60: ...CABLE ROUTING 2 41 ...

Page 62: ...CABLE ROUTING 2 43 ...

Page 65: ......

Page 143: ...HANDLEBAR 4 42 Throttle cable free play 2 0 4 0 mm 0 08 0 16 in ...

Page 162: ...CHAIN DRIVE 4 61 ...

Page 165: ......

Page 240: ...CARBURETOR 6 9 ...

Page 242: ...IGNITION SYSTEM 7 1 EAS27090 IGNITION SYSTEM EAS27100 CIRCUIT DIAGRAM ...

Page 246: ...ELECTRIC STARTING SYSTEM 7 5 EAS27160 ELECTRIC STARTING SYSTEM EAS27170 CIRCUIT DIAGRAM ...

Page 252: ...CHARGING SYSTEM 7 11 EAS27200 CHARGING SYSTEM EAS27210 CIRCUIT DIAGRAM ...

Page 255: ...CHARGING SYSTEM 7 14 ...

Page 256: ...LIGHTING SYSTEM 7 15 EAS27240 LIGHTING SYSTEM EAS27250 CIRCUIT DIAGRAM ...

Page 260: ...SIGNALING SYSTEM 7 19 EAS27270 SIGNALING SYSTEM EAS27280 CIRCUIT DIAGRAM ...

Page 264: ...CARBURETOR HEATING SYSTEM 7 23 EAS27490 CARBURETOR HEATING SYSTEM EAS27500 CIRCUIT DIAGRAM ...

Page 267: ...CARBURETOR HEATING SYSTEM 7 26 ...

Page 268: ...ELECTRICAL COMPONENTS 7 27 EAS27972 ELECTRICAL COMPONENTS ...

Page 270: ...ELECTRICAL COMPONENTS 7 29 EAS27980 CHECKING THE SWITCHES ...

Page 284: ...ELECTRICAL COMPONENTS 7 43 ...

Page 291: ......

Page 292: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN ...

Page 293: ...WIRING DIAGRAM YFM25RY YFM25RSEY YFM25RSE2Y ...