HOIST

OPERATION & MAINTENANCE

5

P/N: 11854801 REV. AC

September 2017

Yale

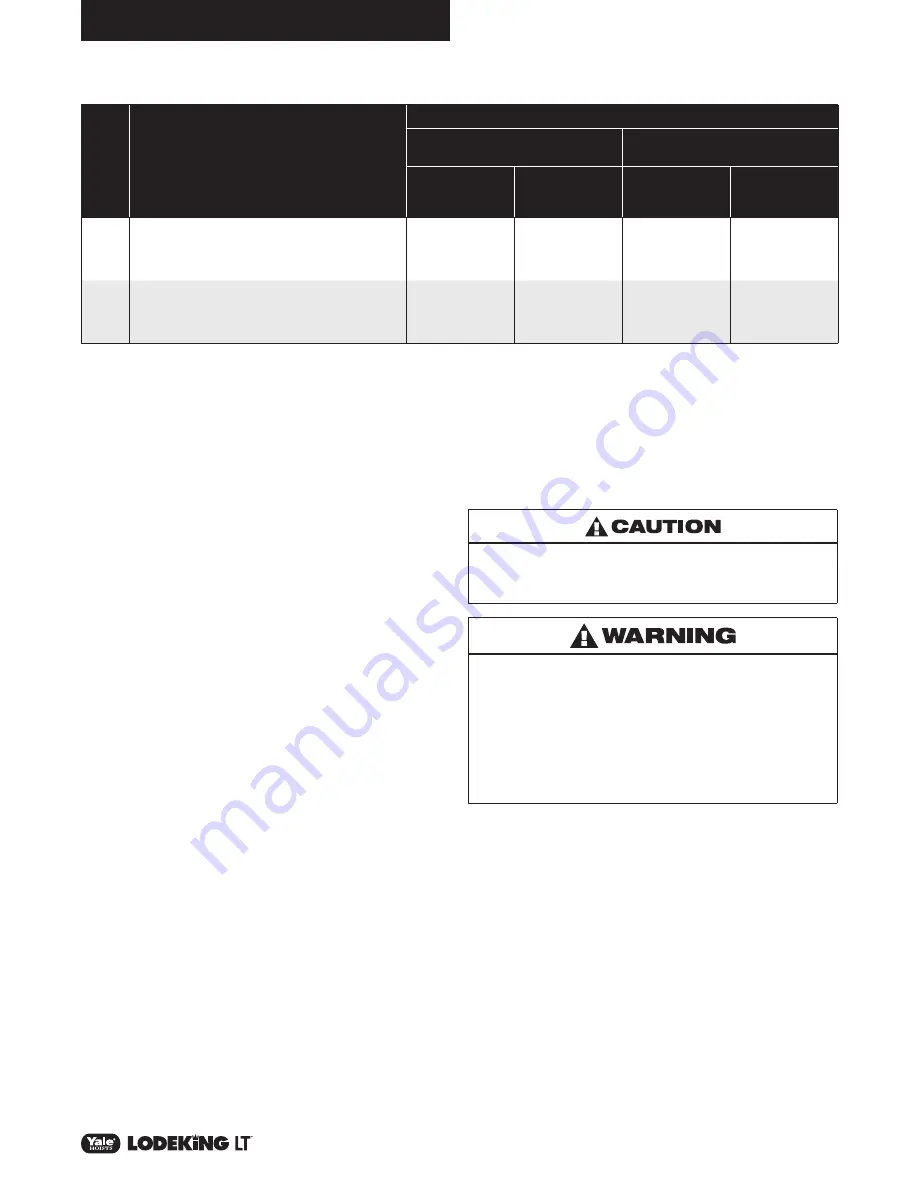

Hoist

Duty

Class

Typical Areas

of Application

Operational Time Ratings

Uniformly Distributed

Work Periods

Infrequent Work Period

Hoist Running 50% Time

(3)

Max. on Time

Min./Hr.

(4)

Max. No. of

Starts/Hr.

(5)

Max. Time From

Cold Start Min.

(6)

Max. No. of

Starts

H3

General Machine Shop, fabricating, assembly, storage and

warehousing. Where loads and utilization are randomly

distributed, with total running time of equipment not

exceeding 15-25% of the work period.

15

150

30

200

H4

High volume handling in steel warehousing, general

machine shops, fabricating, assembly, mills and foundries.

Total running time does not exceed 35% of work period.

Loads at or near rated capacity frequently handled.

30

300

30

300

YALE HOIST DUTY SERVICE CLASSIFICATIONS

DECK MOUNT INSTALLATION INSTRUCTIONS

1. It is the responsibility of the Crane Builder to ensure that the trolley

system meets all applicable standards and guidelines available from

but not limited to ANSI, HMI and CMAA in terms of load ratings,

duty cycles and factors of safety.

2. CMCO does not participate in or condone field modification or

product usage in a manner inconsistent with the design function. It

is the responsibility of the crane builder to ensure compliance with

CMCO specifications and guidelines for mounting and operation of

this equipment

3. Refer to drawing C45570401 LodeKing Deck Mount Clearance

Diagram and the specific order clearance diagram for details such

as frame loading, mounting pad dimensional specifications and

overall unit envelope dimensions

4. Weld on shear blocks shall be attached by a qualified welder using

a weld that has been sized properly for the application, and welded

per AWS D14 Specifications.

5. The weld on shear blocks and the angle iron feet shall not be

subject to loading in the vertical direction. The shear block systems

is designed to resist hoist motion in the horizontal direction only.

Hoist frame loading in areas not approved by CMCO is prohibited.

6. Welding the shear blocks while still attached to the hoist frame is

not recommended due to the possibility of stray voltage from the

welding operation damaging the electrical components present on

the hoist

7. The trolley mounting surfaces shall be flat and in the same plane

within 0.015”

8. Hoist frame loading in areas not approved by CMCO is prohibited

9. Deck mount angles to shear block mounting bolts shall be installed

with Loctite, and torqued to 300-325 ft-lbs. Bolts shall be c

hecked

at least yearly for signs of loosening.

INSTALLATION INSTRUCTIONS

Before the unit is shipped from the factory it is rigidly tested and

carefully adjusted for proper operation. However, the following points

must be checked to insure correct installation and avoid damage to

the hoist.

1.

ROPE AND DRUM:

Check the hoist rope for any signs of

damage and make sure it lies properly in the grooves of

the drum and sheaves. Make sure the rope is well lubricated.

2.

LUBRICATION:

Every attempt has been made to ship the

hoist with the proper amount of lubricating oil in the gearcase.

Before placing the unit-in operation, check the level on the sight

gauge. The oil should be level with the level hole. If more oil is

needed, consult the Lubrication Chart. Also make sure breather

plug hole is cleared.

3.

CURRENT SUPPLY:

make sure the electric current supply

corresponds with the rating listed on the hoist nameplate.

Make sure duty cycle capabilities of hoist are fully understood

by all operators.

4.

ELECTRICAL CONNECTIONS:

Open the control box and

check all the electrical connections ~ to be sure they are tight

and that none of the hardware vibrated loose during shipment.

5.

PUSH BUTTON CONTROL:

THE HOIST MUST BE GROUNDED. TO DO THIS CONNECT

A SUITABLE GROUND WIRE IN THE SUPPLY WIRING TO A

SOLID GROUND AND TO THE SUPPLY GROUNDING LUG

SUPPLIED IN THE HOIST CONTROL PANEL.

TO INSURE CORRECT OPERATION OF THE SAFETY LIMIT

STOPS, IT IS VERY IMPORTANT THAT THE HOOK TRAVEL

IS IN THE HOISTING DIRECTION WHEN THE ‘UP’ BUTTON

IS PRESSED. IF IT IS NOT, INTERCHANGE ANY TWO OF THE

MOTOR LEADS IN THE MOTOR CONDUIT BOX. DO NOT

CHANGE PUSHBUTTON WIRING. INTERCHANGING WIRES

ON THE LINE SIDE OF THE INVERTER WILL NOT AFFECT

SHAFT ROTATION DIRECTION. IF THE HOIST IS OPERATED

WITH INCORRECT POWER CONNECTIONS, THE SAFETY

LIMIT STOPS WILL BE INEFFECTIVE AND SERIOUS DAMAGE

AND DANGEROUS ACCIDENTS MAY RESULT.

Summary of Contents for Lodeking LT Series

Page 50: ...NOTES ...

Page 51: ...NOTES ...