Electric Chain Hoist CPE/F

5

4.3 ELECTRIC CHAIN HOIST WITH TROLLEY

The units are delivered pre-assembled and are built to fit beam range

A or B which is given on the name plate (Tab. 1). Prior to installation

ensure that the flange width is within the limits indicated.

In 1-strand configuration the suspension hook is to be installed centred

on the marking "1/1" on the main frame assy. , in 2-strand configuration

centred on the marking "2/1",

In 3- and 4-strand configuration the suspension hook is to be installed

centred on the marking "1/1" on the main frame assy.

Attention:

Secure the two suspension pins with locking plate after

assembly.

Selection and calculation of the suitable suspension point and beam

construction are the responsibility of the user.

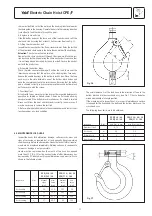

Assembly of the trolley 1,6 - 5 t (see Fig. 10)

1. Unscrew the locking nuts (item 9) and hex nuts (item 2) from the

crossbars (item 1) and remove both side plates (item 6) from the trolley.

2. Measure the flange width of the beam (see Fig. 10 - measure b).

3. Adjust measure B between the shoulders of the round nuts (item 5)

on the threaded crossbars (item 1). Ensure that the 4 bores in the round

nuts face towards the outside. Adjust the measure B to equal measure

b plus 4 mm. Measure A must be 2 mm on either side and the centre

traverse (item 4) must be centred between the round nuts.

4. Replace one side plate (item 6):

Replace one side plate ensuring that the roll pins (item 8) engage into

one of the 4 bores in the round nuts (item 5). To achieve this it may be

necessary to rotate the round nuts slightly.

5. Replace the washers (item 3) and tighten the hex nuts (item 2). Screw

on the locknuts (item 9) finger-tight and tighten a further ¼ to ½ turn.

Attention:

The locknuts must always be fi tted.

No. Description

1 Crossbar

2 Hex. nut

3 Washer

4 Centre traverse

5 Round nut

6 Side plate

7 Trolley wheel

8 Roll pin

9 Locknut

10

Roll pins

B

b

10

5

3

2

9

Fig. 10

A

A

A

B

b

2

9

1

3

4

5

8

6

7

Tab. 1

Capacity

Beam

Flange width

Flange thickness

[kg]

range

[mm]

[mm]

von

bis max.

1.600 - 5.000

A

98

180

27

1.600 - 5.000

B

180

300

27

7.500 - 10.000

B

125

310

40

2

mm

Fig. 9

Summary of Contents for CPEF

Page 15: ...Electric Chain Hoist CPE F 15...

Page 16: ...Electric Chain Hoist CPE F 16...

Page 17: ...Electric Chain Hoist CPE F 17...