Electric Chain Hoist CPE/F

3

1. GENERAL

INFORMATION

Attention:

All users must read these operating instructions carefully prior

to the initial operation. These instructions are intended to acquaint the

user with the hoist/trolley and enable him to use it to the full extent of

its intended capabilities.

The operating instructions contain important information on how to

handle the hoist/trolley in a safe, correct and economic way. Acting

in accordance with these instructions helps to avoid dangers, reduce

repair costs and downtime and to increase the reliability and lifetime

of the hoist/trolley.

Anyone involved in doing any of the following work with the hoist/trolley

must read the operating instructions and act accordingly:

• Operation, including preparation, trouble shooting and cleaning

• Maintenance, inspection, repair

• Transport

Apart from the operating instructions and the accident prevention act

valid for the respective country and area where the hoist / trolley is used,

also the commonly accepted regulations for safe and professional work

must be adhered to.

The user is responsible for the proper and professional instruction of

the operating personnel.

Every unit leaving the factory is furnished with a test certifi cate that

shows the serial number of the hoist / trolley. This certifi cate has to be

fi led together with the inspection manual.

The continuous sound level at the place of work is equal to > 70 dB.

The measurements were taken at a distance of 1 m from the hoist at 9

positions in accordance with DIN 45635, precision class 2.

2. CORRECT

OPERATION

Maximum capacity

The Yale electric chain hoist series CPE/F has been designed to lift

and lower loads up to the rated capacity. The lifting capacity indicated

on the hoist/trolley is the maximum safe working load which must not

be exceeded.

Danger

zones

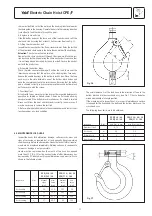

• Do not allow personnel to pass under a

suspended load (see Fig. 2).

• After lifting or tensioning, a load must

not be left unattended for a longer

period of time.

• Start moving the load only after it has

been attached correctly and all personnel

are clear of the danger zone.

Attaching the hoist / trolley

• The operator must ensure that the hoist / trolley is attached in a

manner that does not expose himself or other personnel to danger by

the hoist, trolley, chain(s) or the load.

TABLE OF CONTENTS

PAGE

1. General

information

3

2. Correct

operation

3

Maximum

capacity

3

Danger

zones

3

Attaching the hoist / trolley

3

Temperature

range

4

Theoretical service life

4

Regulations, maintenance / repair

4

3. Incorrect

operation

4

4. Assembly

4

4.1 Inspection before assembly

4

4.2 Electric chain hoist with hook suspension

4

4.3 Electric chain hoist with trolley

5

Assembly of the trolley

5

Assembly, Shortening or extending the hand chain

6

4.4 Electrical connection

6

Preparation

6

Connecting to the power supply

6

5. Functional test after assembly

8

6. Commissioning

8

Inspection before initial operation

8

Inspection by a crane expert

8

7. Operation

8

Installation, service, operation

8

Inspection before starting work

8

Inspection of load chain

8

Inspection of chain end stop

8

Inspection of chain reeving

8

Inspection of suspension and load hooks

8

Attaching the load

8

Inspect the traverse (for trolleys)

8

Check adjustment of trolley width

8

Traversing the trolley

8

Attaching the load

9

Lifting / lowering the load

9

Emergency

stop

9

8. Service

9

8.1 Daily checks

9

8.2 Regular inspections, service and testing

10

8.3 Load chain

10

Lubricating the load chain

10

Inspecting the load chain for wear

10

Replace the load chain

10

1-strand design, 2-strand design

10

8.4 Maintenance of suspension and load hooks

11

8.5 Maintenance of trolley

12

8.6 Maintenance of overload protection

12

Overload

protection

12

Adjustment of overload protection

12

8.7 Maintenance of gearbox

12

Oil

change

12

Disassembly and reassambly

12

8.8 Maintenance of motor

13

Motor

13

Disc

brake

13

8.9 Electric chain hoist in general

13

Fig. 2

Summary of Contents for CPEF

Page 15: ...Electric Chain Hoist CPE F 15...

Page 16: ...Electric Chain Hoist CPE F 16...

Page 17: ...Electric Chain Hoist CPE F 17...