Electric Chain Hoist CPE/F

11

chain must be fi tted so that the welds on the standing links face towards

the chain guide in the housing. Operate the hoist in the lowering direction

(

-button) to feed the chain through the hoist.

4. Replace chain end stop

Slide the buff er pad over the loose end of the load chain and refi t the

chain end stop ensuring that at least 1 link remains free (see Fig. 1).

5. Fitting the chain anchor bolt

Inspect the chain anchor bolt for fl aws, cracks or burrs. Enter the last link

of the other load chain end into the slot in theunderside of the hoist body.

Attention:

The chain must not be twisted.

Now enter the chain anchor bolt through the side bore. Move the last

link back and forth while entering the chain anchor bolt to ensure that

it is not trapped and damaged by the anchor bolt. Secure the anchor

bolt with the grub screw.

6. Assemble the bottom block

Check the idler sheave for damage. Position the load chain over the

idler sheave ensuring that the welds on the standing links face away.

Grease the needle bearings in the bottom block halves. Place the load

hook assy in the slot provided in one of the bottom block halves and

push the complete unit onto the idler sheave. Ensuring that the buff er

pad is situated correctly in its groove replace the second bottom block

half and secure with the screws.

7. Functional test

All units with two or more chain strands must be inspected before every

operation for twisted or kinked chains. Chains on 2-strand units may

become twisted if the bottom block is rolled over. If a strand is twisted

disconnect it from the hoist and re-thread it correctly. In some cases it

may be necessary to remove the last link.

8. Before initial operation lubricate the unloaded chain and test all hoist

functions under a no-load condition.

8.4 MAINTENANCE LOAD HOOK

Inspect the hooks for deformation, damage, surface cracks, wear and

signs of corrosion as required but at least annually. Adverse working

conditions may dictate shorter periods. Hooks that do not fulfi l all require-

ments must be replaced immediately. Welding on hooks to compensate

for wear or damage is not permissible.

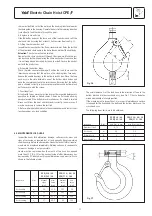

Hooks must be replaced when the mouth of the hook has opened

more than 10 % (Fig. 15) or the nominal value of other dimensions has

decreased by 5 % due to wear. Nominal dimensions and wear limits are

shown in the following table.

Fig. 16

CPE/F 16 / 20

CPE/F 32 / 40 / 50

CPE/F 25 / 30

CPE/F 75 / 100

Inspection

Dim.

nominal

min.

nominal

min.

value

value

value

value

[mm]

[mm]

[mm]

[mm]

Hook

saddle

b

2

24

22,8

29,5

28

Hook

saddle

h

2

35

33,2

44,5

42,3

Hook

opening

a

2

43

47,3 54

59,4

Hook

opening

a

1

37

40,7 46 50,6

The axial clearance

Δ

of the load hook in the direction of force in the

bottom block and in the cross head assy. (see Fig. 17) has to be deter-

mined additionally at every inspection.

If the measurement is larger than 1 mm a special maintenance service

is required for the hook head, the balls and the bottom block resp. the

cross head assy.

The following lower limits are to be obtained:

CPE/F 16 / 20

CPE/F 32 / 40 / 50

CPE/F 25 / 30

CPE/F 75 / 100

Inspection

Dim.

min. Dim. in mm

min. Dim. in mm

Diameter of ball

4,75

5,7

Hook head

α

6,3

7,9

Bottom block

β

8

9,2

Axial clearance

Δ

1 1

Fig. 17

Summary of Contents for CPEF

Page 15: ...Electric Chain Hoist CPE F 15...

Page 16: ...Electric Chain Hoist CPE F 16...

Page 17: ...Electric Chain Hoist CPE F 17...