This type of installation can cause non-warrantable

problems with components and poor operation of the

boiler due to the recirculation of flue products. Multi-

ple vent caps installed in the same horizontal plane

must have a 4 ft clearance from the side of one vent

cap to the side of the adjacent vent cap(s).

Combustion air supplied from outdoors must be free of

particulate and chemical contaminants. To avoid a

blocked flue condition, keep the vent cap clear of

snow, ice, leaves, debris, etc.

Condensate Management

The condensate must be drained properly to protect

the appliance and drainage system. The condensate

from the boiler is acidic. Its pH is between 3.2 and 4.5.

Raypak recommends neutralizing the condensate with

a Condensate Neutralizer kit (Z-12). The neutralizer kit

is connected to the drain system and contains lime-

stone (calcium carbonate) chips to neutralize the pH

level of the condensate. The kit may be added to avoid

long-term damage to the drainage system and to meet

local code requirements.

Vent pipe condensate drains are also required for

installation of the XFyre. Follow vent manufacturer

instructions for location of condensate drains in the

vent. The vent condensate should also be routed

through a neutralization kit, as required by local code

requirements.

The neutralizer kit must be sized to the condensate

generated by the appliance and the vent.

WARNING:

No substitutions of flue pipe or vent

cap material are allowed. Such substitutions would

jeopardize the safety and health of inhabitants.

CAUTION:

In general, the condensate piping from

the appliance must have a downward slope of ¼” per

horizontal foot. Condensate drain traps must be

primed with water to prevent gas flue leaks.

Neutralizers should be checked at least once per

year, and the chips should be replenished as neces-

sary. When replacing the chips, they should be no

smaller than ¾” to avoid blockage in the condensate

piping.

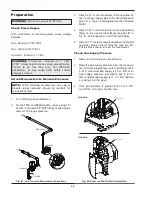

Fig. 27 is a visual guide only

. Follow the man-

ufacturer’s instructions for the installation of the

neutralization kit and condensate drains.

Fig. 27: Visual Guide for Condensate Piping

33

Summary of Contents for 300A

Page 44: ...WIRING DIAGRAM 44...