5/2011

5-4

Phaser 4600/4620 Printer Service Manual

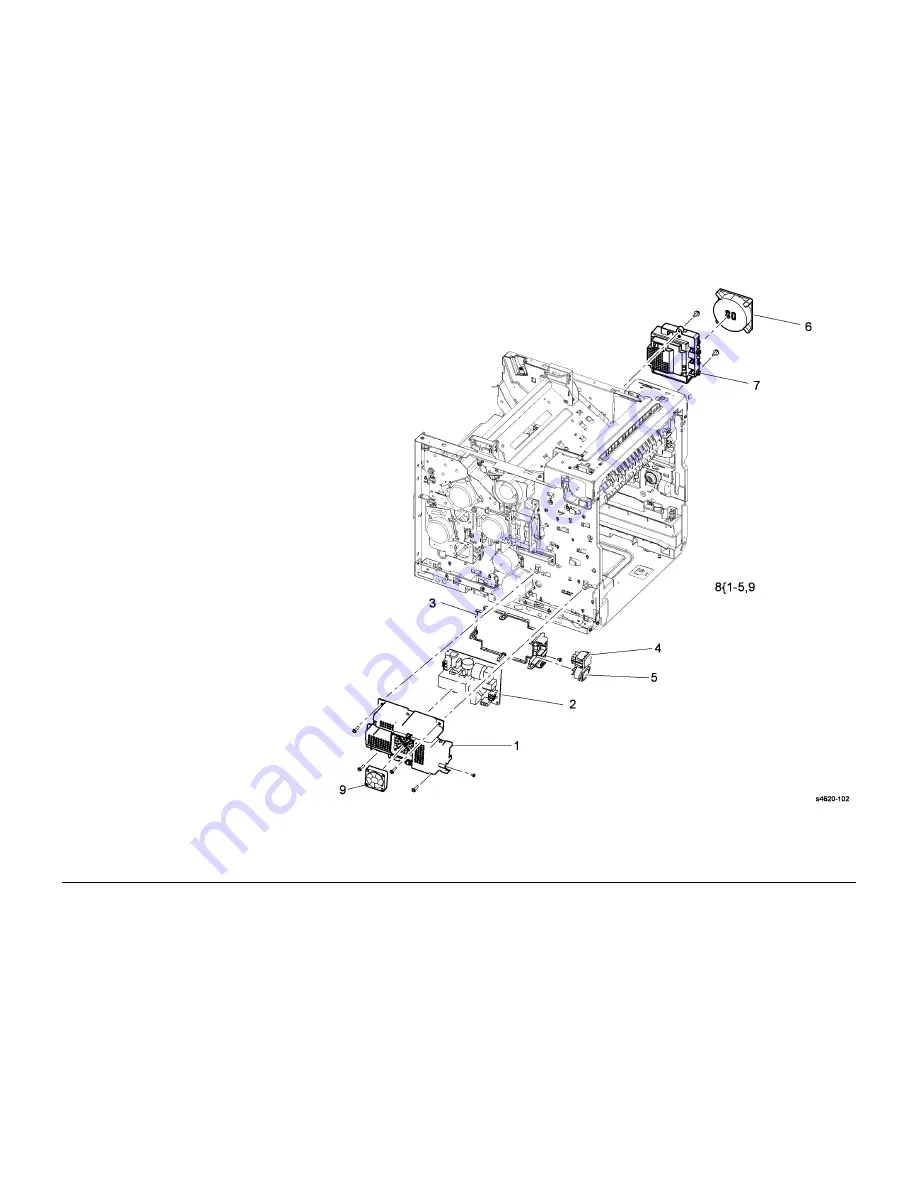

PL 1.15

Revision - Xerox Internal Use Only

Parts Lists

PL 1.15 Fuser Drive Board Assembly

Item

Part

Description

1

–

Fuser drive cover (P/O PL 1.15

Item 8)

2

140N63472

Fuser drive board (110V) (REP 1.2)

–

140N63473

Fuser drive board (220V) (REP 1.2)

3

–

Back cover (P/O PL 1.15 Item 8)

4

–

Main power switch (P/O PL 1.15

Item 8)

5

–

Main power socket (P/O PL 1.15

Item 8)

6

127N07668

SMPS fan (MOT09-500) (REP 1.7)

7

–

Fan duct (Not Spared)

8

001N00525

Fuser drive board assembly (110V)

(REP 1.3)

–

140N63538

Fuser drive board assembly (220V)

(REP 1.3)

9

127N07584

Fan-DC