Wiring Diagrams

FaxCentre F110

12/04

7-5

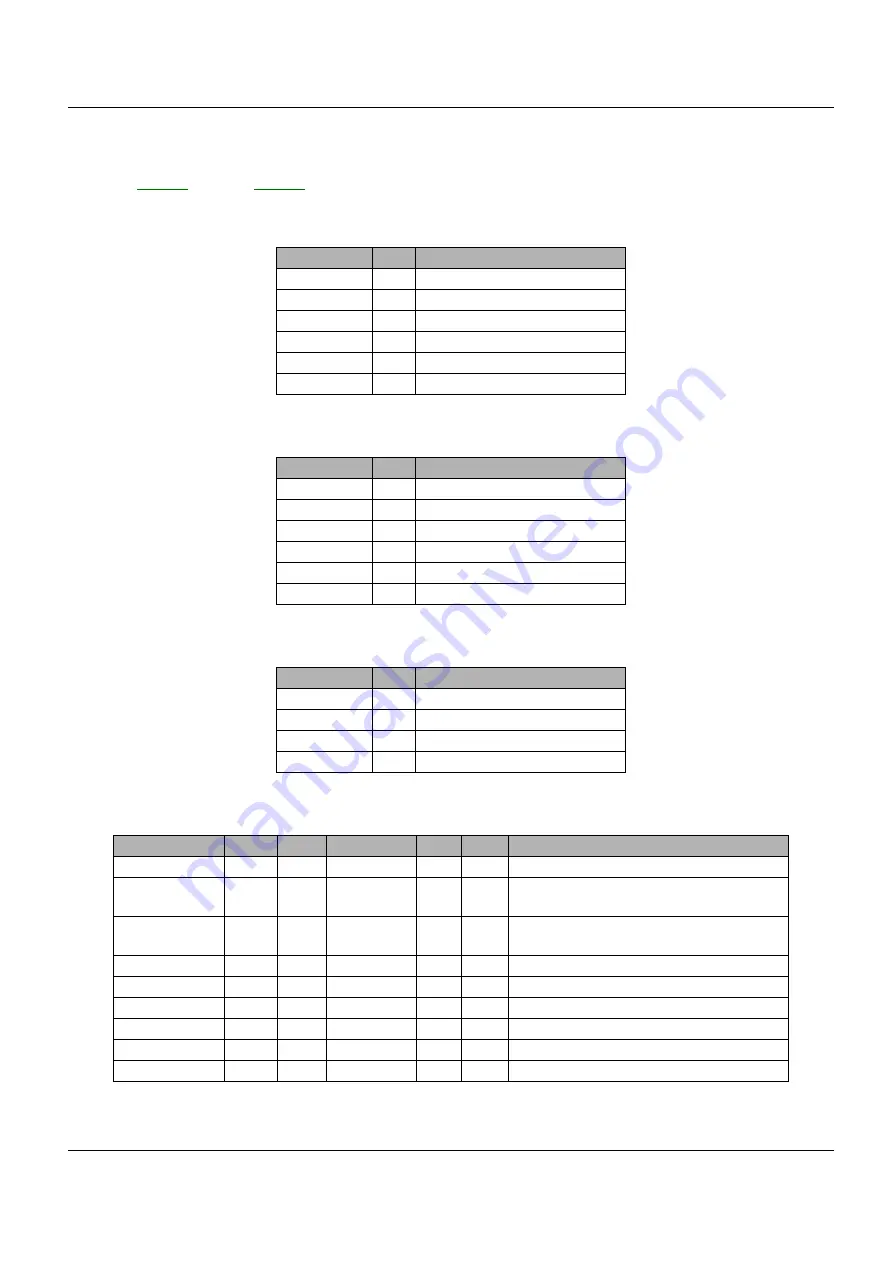

WD 3 External Connection

Refer to

Table 1: Line Connector P701

Name

Pin

Function

NC

1

Not connected

R2

2

Loopback L1

L2

3

Telephone line pair

L1

4

Telephone line pair

R1

5

Loopback L2

NC

6

Not connected

Table 2: External Phone connector P700

Name

Pin

Function

NC

1

Not connected

NC

2

Not connected

R2

3

Loopback L1

R1

4

Loopback L2

NC

5

Not connected

NC

6

Not connected

Table 3: Handset connector P901

Name

Pin

Function

MIC-

1

Microphone

GND

2

Ground (Earth)

DECT_EAR 3

Loudspeaker

MIC+

4

Microphone

Table 4: DECT connector(P900)

Signal

Pin

I/O

Digicolor2

Pin

I/O

Comment

Vcc

9

-

-

-

-

Power supply 5V

RxD

8

I

USART1_T

X

145

O

Serial data receive

TxD

7

O

USART1_R

X

143

I

Serial data transmit

-6V

6

-

-

-

NC

DECT_RES

5

-

Reset for the dect base

AGND

4

-

-

-

Analog ground (earth)

Audio_in

3

-

-

-

Audio in

Audio-out

2

-

-

-

Audio out

Agnd

1

-

-

-

Analog ground (earth)

Summary of Contents for FaxCentre F110

Page 1: ...12 04 FaxCentre F110 SERVICE MANUAL ...

Page 4: ...Introduction ii 12 04 FaxCentre F110 Page intentionally blank ...

Page 10: ...Service Call Procedures 1 2 12 04 FaxCentre F110 Page intentionally blank ...

Page 14: ...Status Indicator RAPs 2 2 12 04 FaxCentre F110 Page intentionally blank ...

Page 40: ...Image Quality 3 2 12 04 FaxCentre F110 Page intentionally blank ...

Page 56: ...Repairs Adjustments 4 2 12 04 FaxCentre F110 Page intentionally blank ...

Page 72: ...Repairs Adjustments 4 18 12 04 FaxCentre F110 Page intentionally blank ...

Page 74: ...Spare Parts List 5 2 12 04 FaxCentre F110 Page intentionally blank ...

Page 137: ...General Procedures Information FaxCentre F110 12 04 6 51 GP 17 18 Not Used ...

Page 190: ...General Procedures Information 6 104 12 04 FaxCentre F110 Page intentionally blank ...

Page 192: ...Wiring Diagrams 7 2 12 04 FaxCentre F110 Page intentionally blank ...

Page 198: ...Wiring Diagrams 7 8 12 04 FaxCentre F110 WD 6 Wiring Diagram Figure 1 ...

Page 200: ...Page intentionally blank ...

Page 202: ...XEROX EUROPE ...