5

C

O

N

F

I

G

U

R

A

T

I

O

N

A

N

D

M

A

I

N

T

E

N

A

N

C

E

Wunder-Bar®

Mechanical Post-Mix Dispensers can be configured for any

combination of carbonated or non-carbonated beverages or non-carbonated

premix beverages—up to a total of 14 products total (requires 14 Button Dis-

penser), including soda and plain water. All these combinations are field

convertible without shutting off the dispenser.

Wunder-Bar®

Post-Mix Juice

Dispensers are permanently factory-configured to dispense non-carbonated

juices, mixes, and beverages, only.

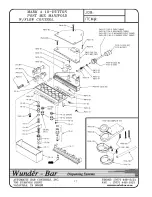

BUTTONS AND BUTTERFLY PLATES

The Buttons and Button Plate can be removed while dispenser is under

pressure (

Fig.10

). After the button plate has been removed, buttons and the

configuration of the dispenser can be changed so that any combination of

carbonated and non-carbonated buttons can be achieved. Simply remove

the butterfly retainer screws (

Fig.11

) and lift out the butterfly plates (stain-

less steel plates with small ball bearings attached) to create various stan-

dard configurations and endless special configurations. The butterfly plate

balls fit into the handle recess. The half moon cutout area of the butterfly

plates are where the retainer and retainer screws are located when attach-

ing the plates to the handle. When replacing the butterfly plates, be careful

not to over-tighten the retainer screws. This may cause the plates to bind.

See Butterfly Maps on pages 8 and 9.

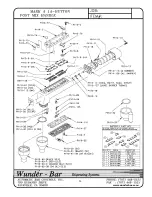

SHUT-OFFS

If it becomes necessary to work on the internal components of the dis-

penser, you must turn off all syrups, water, and carbonated water. The

manifold is equipped with shut-offs (or shut-off screws) for each of the syr-

ups, the soda, and the water (

Fig.12

).

The shut-offs work like a gate valve. There

is a hole through the shut-off that is aligned

in the same direction as the shut-off’s tab

handle. This allows each beverage dis-

penser on the system to be shut off, indi-

vidually, at each dispenser’s brix manifold,

without affecting the other dispensers on

the system.

Turn the shut-offs 90 degrees clockwise to

shut off the flow of all products at the dis-

penser’s manifold (

Fig.13

). .

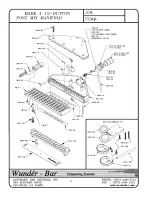

DISCONNECTING DISPENSER FROM BRIX MANIFOLD

After all shut-offs are turned 90° to the OFF position (

Fig.13

), depress

all buttons on the dispensing handle to release pressure between the

manifold and handle. Pull up on kwik klips between the tube collector

and manifold (

Fig.14

). These are called the Interconnect kwik klips. (It

is not necessary to remove the kwik klips). Push the cam knob side-

ways while pulling the manifold away from the tube collector to separate

the manifold from the tube collector(

Fig.15

). A replacement flex-hose

assembly can now be placed onto the brix manifold, the interconnect

kwik klips pushed back into place, shut off screws opened 90 degrees

counter clockwise, and the new dispenser doesn't even have to be re-

brixed!

OR,

repairs can be made in a properly equipped, adequately

lighted area, and out of the way of the bartender. Reinstall the dis-

penser back onto the brix manifold when repairs are completed. Re-

brixing should not be required.

Fig.10

Fig.11

Fig.12

MARK 4 MANUAL

www.wunderbar.com

Fig.13

Shut-Off’s

OPEN

Shut-Off’s

CLOSED

Fig.14

Fig.15

CAM KNOB

Summary of Contents for Mark 4

Page 15: ...15 15 www wunderbar com ...

Page 16: ...16 16 www wunderbar com ...

Page 17: ...17 17 www wunderbar com FR 73 ...

Page 18: ...18 18 www wunderbar com ...

Page 19: ...19 20 www wunderbar com ...

Page 20: ...20 19 www wunderbar com ...

Page 21: ...21 21 www wunderbar com ...

Page 22: ...22 www wunderbar com 22 FR 73 ...

Page 23: ...23 23 www wunderbar com ...

Page 24: ...24 24 www wunderbar com ...

Page 25: ...25 25 www wunderbar com ...

Page 26: ...26 26 www wunderbar com ...