3

B

R

I

X

I

N

G

M

E

T

E

R

I

N

G

S

C

R

E

W

M

A

N

I

F

O

L

D

S

It will be necessary to brix your

Wunder-Bar®

Mechanical Flex Hose bar

dispenser before use. Either a

Wunder-Bar®

Syrup separator and Brix Cup

(

Fig.5

) or a refractometer may be used. Diet products do not contain sugar

and therefore diet products’ ratio may only be measured using a Brix Cup.

Brix ratio is the ratio of syrup concentrate to soda or water. A syrup separa-

tor (p/n PH10-83) is designed to separate the syrup/concentrate from the

soda or plain water, allowing for proper measurement of products. A Brix

Cup (p/n PH10-35) allows the user to visually compare and confirm the ra-

tios of soda-to-syrup and water-to-syrup. A refractometer (Not available

from Wunder-Bar) is a hand-held optical device used to measure the

amount of sugar in solution in beverages containing sugar.

In order for accurate Brix measurements or readings to be made, it will be

necessary to "ice down" the cold plate, by covering the cold plate located in

the bottom of the ice bin with a minimum of 4” to 6” of ice. If a mechanically

refrigerated beverage chilling system is to be used, instead of a cold plate,

turn ON the refrigerated, re-circulating beverage unit and allow it to “chill

down” to normal operating temperature before attempting to take Brix read-

ings or measurements. Once the cold plate or refrigerated unit have

reached temperature, dispense approximately 10 to 12 ounces of each bev-

erage just before attempting to “read” each products’ brix.

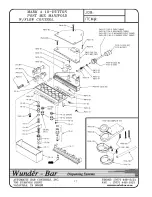

SETTING THE SODA AND WATER FLOW RATES

Set the flow rate to your specifications or to the nominal flow rate of 5 oz of

soda in 3 seconds. Dispense soda, through nozzle, into the large chamber

of the Brix Cup or a measuring cup. Squeeze the two tabs together and re-

move the manifold cover. Adjust the brix screw at the "S" position on the

product manifold by turning the screw

counter-clockwise or “out” to in-

crease

flow rates and

clockwise or “in” to decrease

flow rates (

Fig.6

).

The brix screws are the exposed screws on the product manifold. Do not

turn the “Shut-Offs” to adjust the brix ratio. The shut-offs are closest to the

input fitting side of the manifold and are open when the Shut-Off tabs or

screw slots are in line with the flow of product through the manifold (

see

Fig.7

). Repeat the adjustment process to set the water flow rate

to 5 oz. of water in 3 seconds.

ADJUSTING THE BRIX RATIOS

Now that the soda and water flow rates are set, product brixing

may begin. The "L" button corresponds to the "L" position on the product

label at the manifold. The "C" button corresponds with the "C" position on

the manifold, "T" for "T", etc. The syrup brix screws are adjusted in the

same manner as Soda and Water Brix Screws;

counter-clockwise or "out"

increases

flow rates,

clockwise or "in" decreases

flow rates. The most

common ratio for Post-mix beverages is 5:1 (5 parts soda or water to 1 part

syrup). However, some specialty beverages have 5.5:1 or higher ratios.

Some juices and mixers have ratios as low as 1:1 to 2:1. Always read the

BIB (Bag-In-Box) syrup container label for ratio specifications before start-

ing. The small chamber (syrup side) of brix cup should fill to 1 oz. in the

same amount of time it takes to fill the large chamber 5 oz. of soda or wa-

ter—confirming a 5:1 brix ratio (

Fig.5

). If the product was 4:1 ratio, the small

chamber would fill to the same 1 oz. mark, but the soda or water would fill to

4 oz. Repeat until all products are properly brix ratio’d.

SECONDARY WATER BRIX SCREW (Fig.8)

All

Wunder-Bar®

Post-Mix and Juice dispensers have a “Secondary Water

Adjustment Screw” to enable juices and beverages with 2:1 and 1:1 ratios to be dispensed through buttons

located under the lower right Butterfly Plate. The Secondary Water Brix Screw is factory set to the “open”

position. Use a small bladed screwdriver to turn the screw Clockwise or “in” to decrease water flow to

achieve 2.1 to 1:1 ratios for products like tomato juice and Bloody Mary Mix.

MARK 4 MANUAL

www.wunderbar.com

Fig.6

Fig.7

Fig.8

Fig.5

Shut-Off’s

in OPEN

Position

3

Summary of Contents for Mark 4

Page 15: ...15 15 www wunderbar com ...

Page 16: ...16 16 www wunderbar com ...

Page 17: ...17 17 www wunderbar com FR 73 ...

Page 18: ...18 18 www wunderbar com ...

Page 19: ...19 20 www wunderbar com ...

Page 20: ...20 19 www wunderbar com ...

Page 21: ...21 21 www wunderbar com ...

Page 22: ...22 www wunderbar com 22 FR 73 ...

Page 23: ...23 23 www wunderbar com ...

Page 24: ...24 24 www wunderbar com ...

Page 25: ...25 25 www wunderbar com ...

Page 26: ...26 26 www wunderbar com ...