8

MARK 4 MANUAL

www.wunderbar.com

TUBE COLLECTOR

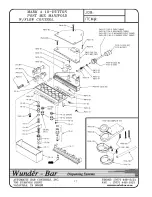

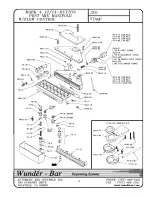

When the tube collector is separated from the brix manifold, the tube collec-

tor cover plate can be removed to expose the product tubing (

Fig.31

). On a

8 to 10 button dispenser, the syrup tubes in positions 1, 3, 8, and 10 (

see

Fig.31

) are standard syrup tubes. The yellow tubes in positions 2, 4, 7, and

9 (

see Fig.31

) are syrup barrier tubes which should be used for energy

drinks and pungent syrups such as root beer and punch.

The blue tubes in

positions 5 and 6 are Soda and Water.

NOTE: All positions with barrier

tubes are indicated by yellow highlighted numbers on the manifold

label located on top of the tube collector.

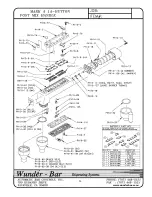

All syrup positions have “B” interconnect fittings and red “B” lock rings. The

Soda and Water positions have “A” interconnect fittings and red “B” lock

rings. The letter B is molded into the side of the “B” interconnect fittings.

(

Fig.32

). The letter A is molded into the “A” interconnect fittings(

Fig.33

).

12 button dispensers have barrier tubes in syrup positions 4, 5, 10 and 11.

14 button dispensers have barrier tubes in syrup positions 4, 5, 10, and 11.

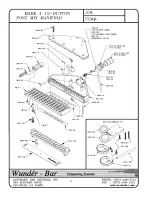

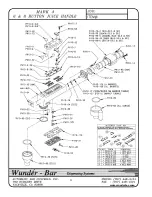

HANDLE REMOVAL

After the dispenser has been depressurized: Remove the four slot screws in

the rear of handle heel. Slide the heel back and away from the handle

(

Fig.34

). The split heel may be separated (

Fig.34

) and removed from the

sheathing for replacement. Loosen and remove the two retainer posts from

the rear of the handle, using a 5/16” hex driver, a 5/16” or small adjustable

wrench. The top center of the retainer plate is marked with a stamped num-

ber “10”. Pull the retainer plate and tubing (with ferrules and caps) away

from the handle. This allows for removal and replacement of the tube seal

o-rings and ferrule caps and ferrules.

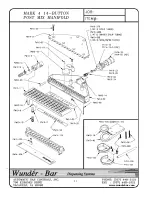

REPLACING A PRODUCT TUBE

Disconnect the handle and sheathing assembly from the manifold. Remove

the Tube Collector Cover screws to gain access to the tube-ends and inter-

connect fittings. Lift up on the desired tube’s interconnect fitting and unsnap

it to separate it from the tube collector. The Individual tube can now be re-

placed in the field. Remove the four screws from the handle heel and slide

the heel and sheathing away from the handle. Loosen and remove the two

retainer posts, using a hex driver, wrench, or pliers, from the rear of the han-

dle. NOTE: The number “10” is stamped into the retainer plate at the top to

aid proper tubing to handle orientation during re-assembly. Pull the retainer

plate and tubing (with ferrules and caps) away from the handle.

A new tube assembly, with an interconnect fitting and lock ring installed,

should be ordered from the factory. Cut the old interconnect fitting off of the

old tube. Tape the new tube’s end to the end of the old tube. Slowly pull

the tube through the sheathing all the way to the back of the retainer plate.

Un-tape the tubes and discard the old tube. Insert the new tube’s end

through the open hole in the retainer plate about 1 to 1-1/2”. Dip the tube

end in hot water for 3 seconds and then install the ferrule into the tube end.

Install the ferrule cap onto the tube end with ferrule installed. Push all of the

tubes’ back to the retainer plate surface. Align the mark to the top of the

handle while inserting all ten tube ends with ferrules and caps back into their

o-rings in the back of the handle. Once all ten are properly inserted, re-

install the two retainer posts while visually confirming that all ten ferrule caps

are centered in their respective tube seal o-rings. Do not over-tighten the

retainer posts. Reinstall the heel and all four heel screws. Do not over-

tighten the screws.

R

E

P

A

I

R

Fig.33

Fig.34

Fig.32

Fig.31

STA

N

D

A

RD

STA

N

D

A

RD

WA

T

E

R

SO

D

A

BA

RR

IER

STA

N

D

A

RD

BA

RR

IER

BA

RR

IER

BA

RR

IER

STA

N

D

A

RD

1 2 3 4 5 6 7 8 9 10

Summary of Contents for Mark 4

Page 15: ...15 15 www wunderbar com ...

Page 16: ...16 16 www wunderbar com ...

Page 17: ...17 17 www wunderbar com FR 73 ...

Page 18: ...18 18 www wunderbar com ...

Page 19: ...19 20 www wunderbar com ...

Page 20: ...20 19 www wunderbar com ...

Page 21: ...21 21 www wunderbar com ...

Page 22: ...22 www wunderbar com 22 FR 73 ...

Page 23: ...23 23 www wunderbar com ...

Page 24: ...24 24 www wunderbar com ...

Page 25: ...25 25 www wunderbar com ...

Page 26: ...26 26 www wunderbar com ...