Installation and Operational Instructions for ROBA

®

-diskstop

®

Type 894.5_ _._ _ Size 10

(B.8.4.5.EN)

23/03/2017 TK/TL/GC/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 12 of 16

www.mayr.com

, E-Mail:

Adjustment

The brakes are equipped manufacturer-side with

the respective springs for the braking force

stated on the Type tag. Adjustment is not

necessary. Adaptions or modifications are not

permitted as a rule. This rule also applies to the

manufacturer-side adjusted noise damping.

The microswitches are also adjusted manufacturer-side.

Despite great care during the manufacturer-side adjustment, re-

adjustment might be necessary after installation due to

transportation and handling. Furthermore, such switches

cannot be considered fail-safe.

Please observe the sections Release Monitoring and Wear

Monitoring.

Noise Damping (Item 11 / Fig. 1):

The noise damping was set and adjusted

manufacturer-side. However, this component is

subject to ageing dependent on the application

or operating conditions (torque adjustment,

switching frequency, ambient conditions,

system vibrations etc.).

Replacing the damping element is only

permitted at the

mayr

®

site of manufacture.

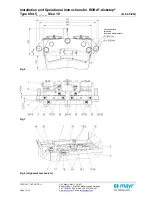

Brake Installation (Figs. 1

– 8)

The brake is pre-assembled manufacturer-side.

1. Release the brake mechanically using a suitable auxiliary

device.

2. Push the released brake over the brake disk and position it

so that both hexagon head screws (10) can be screwed in.

While pushing the brake over the brake disk,

please make sure that the friction linings are

not damaged.

3. Screw in the hexagon head screw (10) and tighten to a

tightening torque of 710 Nm

.

4. Remove the auxiliary device for releasing the brake.

5. Switch the brake 3 - 4 times so that it aligns with the brake

disk.

6.

Check that the brake moves axially on the pad (7). It

must be possible to move the opened brake in the guide

by hand. On an engaged brake, there must be a gap of at

least 2 mm between the pad (7) and the counterplate (3)

as well as between the pad (7) and the armature disk (2),

see Fig. 7.

7.

Check the air gaps "a" (Fig. 2) between the coil carrier

(1) and the armature disk (2).

In new condition, the air gap "a" must be max. 1 mm on a

de-energised brake. Measurements on both sides at friction

pad (4) level

– calculate the average.

8. On the de-energised brake, tighten the cap screws (17) with

10 Nm.

9. Energise the brake.

10. Measure the effective air gap between the friction lining and

the side of the brake disk facing away from the screw-on

surface on the right and left-hand sides and calculate the

difference between the measurement values.

The

differential dimension must be < 0.3 mm

.

11. Turn the brake disk. The brake disk must not rub against

anything.

Installation of Bowden Cable Hand Release

The hand release is pre-assembled manufacturer-side.

In order to install the Bowden cable, the lock washer (6.2) must

be mounted on the correct side. If this is not the case, the lock

washer (6.2) must be screwed off and screwed onto the opposite

side.

The hand release lever (6.1) can be pivoted by approx. 30°.

Adjust the Bowden cable so that the hand release can pivot back

to the middle position (after actuation)

=> Functional inspection

.

Brake Inspection

(before brake initial operation)

Visual inspection:

for proper condition of the brake (rust etc.) and no grinding.

Carry out a release inspection:

by energising the brake or manually by actuating the hand

release.

Switch functions inspection of the release monitoring /

for connection as NC contact:

Brake energised

Signal “OFF”

Brake de-energised

Signal "ON"

for connection as NO contact:

Brake energised

Signal “ON”

Brake de-energised

Signal “OFF”

The braking torque is not achieved until after the run-in

procedure has been carried out.

The run-in conditions must be aligned with the manufacturer.

Braking Torque

The (nominal) braking torque is the torque effective in the shaft

train on slipping brakes, with a sliding speed of 1 m/s referring to

the mean friction radius.

The brake is loaded statically when used as a service brake and

loaded dynamically in EMERGENCY STOP operation (part of

the brake equipment against overspeed or inadvertent

movement of the elevator cage). Respectively, there are different

speed values for the friction material, which in practice also

leads to different friction values and therefore braking torques.

The braking torque is dependent on the respective run-in

condition of the friction surfaces.

We recommend allowing the friction surfaces to run in when

installed and under permitted loads.

Friction materials develop their optimum effect only under speed

at the appropriate contact pressure, as continuous regeneration

of the friction surface then takes place (torque consistency).

Furthermore, friction materials (synthetic resin bonded rubber

mixtures) are subject to ageing, which is also influenced, among

other things, by higher temperatures and other ambient

influences. We recommend regular inspection of the braking

torque (1 x per year) including the respective dynamic braking

actions as a refresher.