Installation and Operational Instructions for ROBA

®

-diskstop

®

Type 894.5_ _._ _ Size 10

(B.8.4.5.EN)

23/03/2017 TK/TL/GC/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 14 of 16

www.mayr.com

, E-Mail:

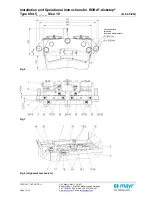

Release Monitoring (Item 12 / Fig. 5 / Optional)

Please carry out a functional inspection before

brake initial operation!

The ROBA

®

-diskstop

®

brakes are supplied optionally with

manufacturer-side installed and adjusted release monitoring

device (12).

A microswitch emits a signal for every brake condition change:

“brake opened” or "brake closed“.

The customer is responsible for a signal evaluation of both

conditions.

From the point at which the brake is energised, a time span of

three times the separation time must pass before the

microswitch signal on the release monitoring is evaluated.

Microswitch Wiring Diagram:

Function

When the magnetic coil is energised in the coil carrier (1), the

armature disk (2) is attracted to the coil carrier (1), the

microswitch emits a signal, the brake is released.

Microswitch Specification

Characteristic values for

measurement:

250 V~ / 3 A

Minimum switching power:

12 V, 10 mA DC-12

Recommended switching

power:

for maximum lifetime

and reliability

24 V, 10...50 mA

DC-12

DC-13 with freewheeling

diode!

Usage category acc. IEC 60947-5-1:

DC-12 (resistance load), DC-13 (inductive load)

Wear Monitoring (Item 13 / Fig. 5 / Optional)

The ROBA

®

-diskstop

®

brakes are supplied optionally with

manufacturer-side installed and adjusted wear monitoring (13)

device.

Function

Due to wear on the friction linings, the air gap “a” between the

coil carrier (1) and the armature disk (2) increases.

Once the maximum air gap of 1.8 mm (see Technical Data) has

been reached, the microswitch contact switches over and emits

a signal.

The friction pads (4) must be replaced.

The customer is responsible for a signal evaluation.

Microswitch Wiring Diagram:

For switch power values, please see Release

Monitoring

Microswitches cannot be guaranteed fail-safe.

Therefore, please ensure appropriate access for

replacement or adjustment.

The switching contacts are designed so that they

can be used for both small switching powers and

medium ones. However, after switching a medium switching

power, small switching powers are no longer reliably possible.

In order to switch inductive, capacitive and non-linear loads,

please use the appropriate protection circuit to protect against

electric arcs and unpermitted loads!

1

4

2

1

4

2

COM Contact

Black connection

NC contact

Grey connection

Connection when

brake closed

NO contact

Blue connection

Connection when

brake released

COM Contact

Black connection

NO contact

Blue connection

Connection when

wear limit

has not yet been

reached

NC contact

Grey connection

Connection when

wear limit

has been reached