Gearless Lift Machine

WSG/WGG-29

Operating Instructions

Code

GM.8.002662.EN

Date

04.02.2019

Version

0.19

Page

31

Subject to changes without notice ! Subject to changes without notice !

EN

4

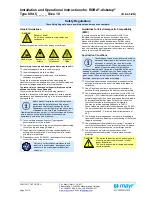

. Tension the Bowden cables on the lever block (1)

using the nuts (10 and 11) on the threaded rod

(12). The manual release levers (4) of the brakes (3)

must not move.

Caution:

Do not operate the lever (9) during ten-

sioning. The brakes must not be released.

9

10

12

11

2

1

5

. Perform at least three functional tests by actuat-

ing the lever (9) on the lever block (1) until the

brakes are released. (Make a visual check of the

brake air gap; check that the traction sheave can

turn freely.)

A force of ca. 130 N should be required to release

the brakes with a lever length of 0.5 m (if 3 par-

tial brakes are provided). Check the installation if

greater force than this is required.

Warning:

More excessive force (> 150 N with a

0.5 m lever length) is unacceptable, as it can

damage the brakes beyond repair.

Set the lever (9) back to its original position once

the test is completed (check the air gap with the

traction sheave locked).

Ensure that the manual release levers (4) on the

individual partial brakes are back to their original

positions.

9

1

2

0,5

m

ca.

65 Nm

ca.

130 N

4

6

2

6

. Upon completion of the three functional tests,

release the brake once again and mark the posi-

tion of the lever at which the traction sheave

can turn freely.

Restrict the movement of the lever using the disc

(14) to prevent it from being pulled further (with

a tolerance of approx. +3°).

To this end, lock the disc (14) on the threaded

rod (12) in the appropriate position by tightening

the lock nuts (13 and 15).

9 1

2

13

12

14 15

7

. Once this has been done, check once again the

functioning of the manual release unit.

9

1

2

13 14 15

+3°

Original position Brake released

Caution

Install the Bowden cables only with large radii) (bending radius > 0.5 m, if possible). Do not

allow any loops to be formed.

(Rear side of the brake)