Installation and Operational Instructions for ROBA

®

-diskstop

®

Type 894.5_ _._ _ Size 10

(B.8.4.5.EN)

23/03/2017 TK/TL/GC/SU

Chr. Mayr GmbH + Co. KG

Eichenstraße 1, D-87665 Mauerstetten, Germany

Tel.: +49 8341 804-0, Fax: +49 8341 804-421

Page 10 of 16

www.mayr.com

, E-Mail:

Table 2: Switching Times [ms]

Design

min. nominal braking force

max. nominal braking force

Attraction t

2

:

650

650

Drop-out t

0

(DC) from holding voltage / overexcitation:

210 / 260

55 / 60

Drop-out t

50

(DC)

2)

from holding voltage / overexcitation:

320 / 340

100 / 110

Drop-out t

90

(DC)

3)

from holding voltage / overexcitation:

720 / 750

360 / 380

Drop-out t

11

(AC):

600

600

Drop-out t

1

(AC):

1000

1000

2)

Referring to the effective braking force

3)

Referring to the nominal braking force

The stated switching times can only be achieved using the respective correct electrical wiring. This also refers to the

protection circuit for brake control and the response delay times of all control components.

The use of varistors for spark quenching increases the DC-side switching times.

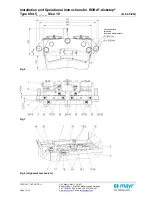

Diagram 2: Torque-Time Diagram

Key

M

Br

= Braking torque

M

L

= Load torque

t

1

= Connection time

t

11

= Response delay on connection

(

≙

t

0

acc. Type Examination Certificate)

t

2

= Separation time

t

4

= Slip time + t

11

t

O

= Overexcitation time

U

N

= Coil nominal voltage

U

H

= Holding voltage

U

O

= Overexcitation voltage

The switching times are dependent on

the respective spring pressure.

U

O

M

Br

0.1 x M

Br

M

L

t

11

t

1

t

2

t

O

U

M

t

t

t

4

U

H