1126700

SmartPAC 2 User Manual

4-32

Initialization Mode

As the backup proceeds, messages like the following display at the top of the screen

Backing up SmartPAC2 data for Tool nnnnnn

where nnnnnn is the tool number, followed by messages like

Backing up SmartPAC2 data for Init Group nn

where nn is the Initialization group number. Then the message

Transferring files...

displays briefly as backup files are written to the USB disk. When the backup is complete,

the following message displays:

Backup Finished!

4.

Press RESET

to return to the Main Initialization Menu.

Restoring Tools from a USB Disk

To restore backed-up tools to a SmartPAC 2, do the following:

1.

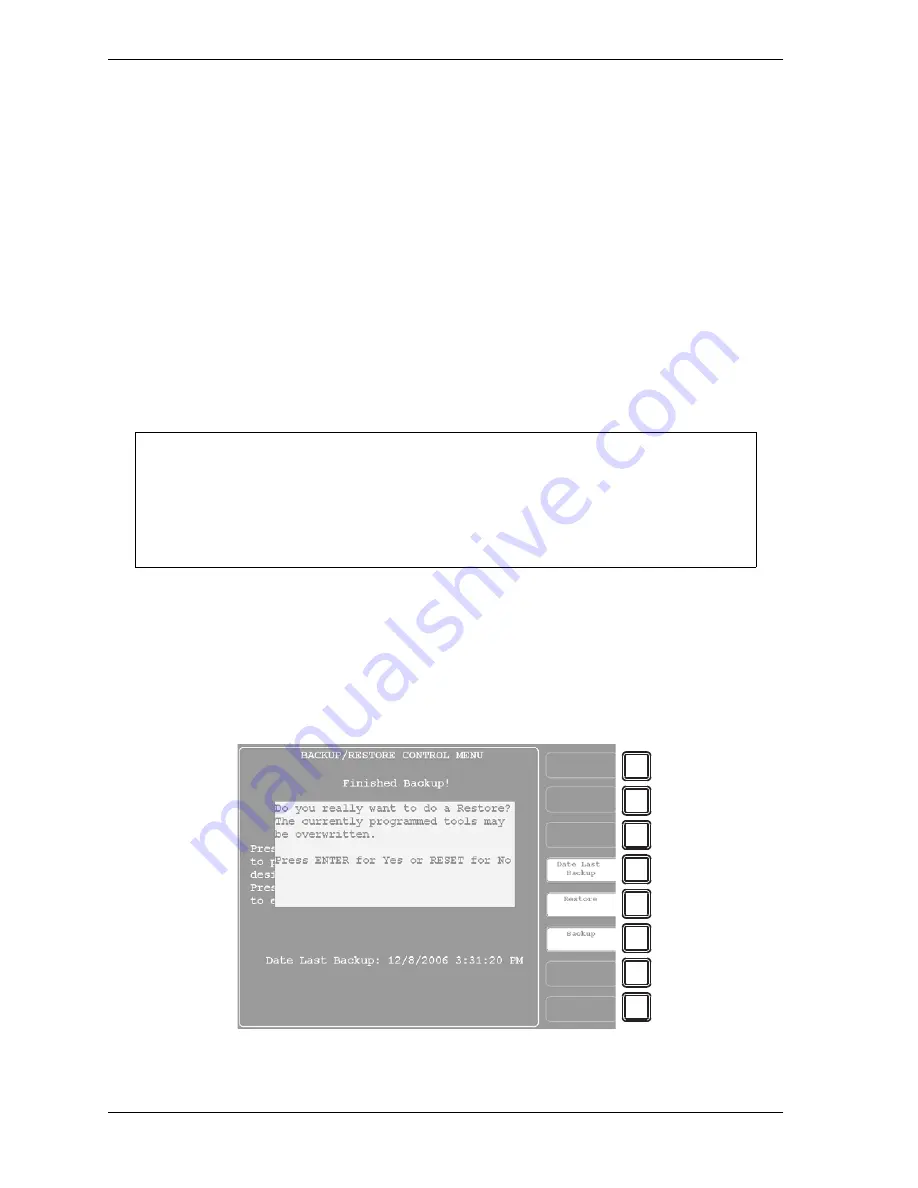

With the USB disk onto which tools have been backed up inserted in the USB connector

(see step 1 of the Backing Up Tools to a USB Disk procedure, page 4-30) and the Backup/

Restore Control Menu (see Figure 4-23) displayed, press the F5 (Restore)

function key. A

window opens, asking you to confirm that you really want to restore tools to the

SmartPAC 2, as shown in Figure 4-24.

You should only need to perform a restore if the SmartPAC 2 tool and Initialization

programming has been corrupted or if the SmartPAC 2 board has been replaced. The

restore process overwrites programming for all your tools and Initialization setups with the

tool and Initialization settings saved during the most recent backup. In performing a

restore, you may lose information that has taken you considerable time to input.

Figure 4-24. Backup/Restore Control Menu with Restore Confirmation Window Displayed

NOTICE

F1

F2

F3

F4

F5

F6

F7

F8

Summary of Contents for SmartPAC2

Page 21: ...1126700 SmartPAC 2 User Manual xviii Table of Contents ...

Page 143: ...1126700 SmartPAC 2 User Manual 4 46 Initialization Mode ...

Page 197: ...1126700 SmartPAC 2 User Manual 5 54 Program Mode ...

Page 233: ...1126700 SmartPAC 2 User Manual 6 36 Run Mode ...

Page 245: ...1126700 SmartPAC 2 User Manual 7 12 Fault Messages ...

Page 271: ...1126700 SmartPAC 2 User Manual B 12 Updating SmartPAC 2 Firmware ...

Page 309: ...1126700 SmartPAC 2 User Manual E 6 Replacing SmartPAC 2 PC Board ...

Page 379: ......

Page 380: ......

Page 381: ......

Page 382: ......

Page 383: ......