ENGLISH

18

-

Check coupling alignment (depending on pump variant),

-

Check if there is unusual noises (cavitations, hissing, purring, …) or

excessive vibrations.

Check point

Periodicity

State of the auxiliary systems

Depends on equipment type.

See dedicated equipment IOM

Motor

See manufacturer IOM

Shaft sealing

Weekly

Leaks from gaskets

Weekly

Oil level and grease quantities

Daily / Weekly / Monthly

Lubricants (ball bearings)

Replacement

frequency

according ball bearing type and

shaft speed

Bearings surface temperature

Monthly

Cleaning

Twice a year

Alignment and coupling wear

Twice a year

Noise, vibrations

Monthly

Anchoring quality

Yearly

Those frequencies are given for information only. They could be used as

a basis to the creation of a maintenance plan when starting a new

installation. Depending on installation conditions and use, the

periodicity will be shortened or prolonged.

9.2.1

LUBRICATION

NORMA V pumps use a bearing bracket fitted with lifetime lubricated

ball bearings (TH) or grease lubricated ball bearings (TM) integrating a

manually actuated greaser. Variants EM and CS have no ball bearing

inside.

For motor lubrication plan, please refer to the machine specific

instructions.

9.2.1.1

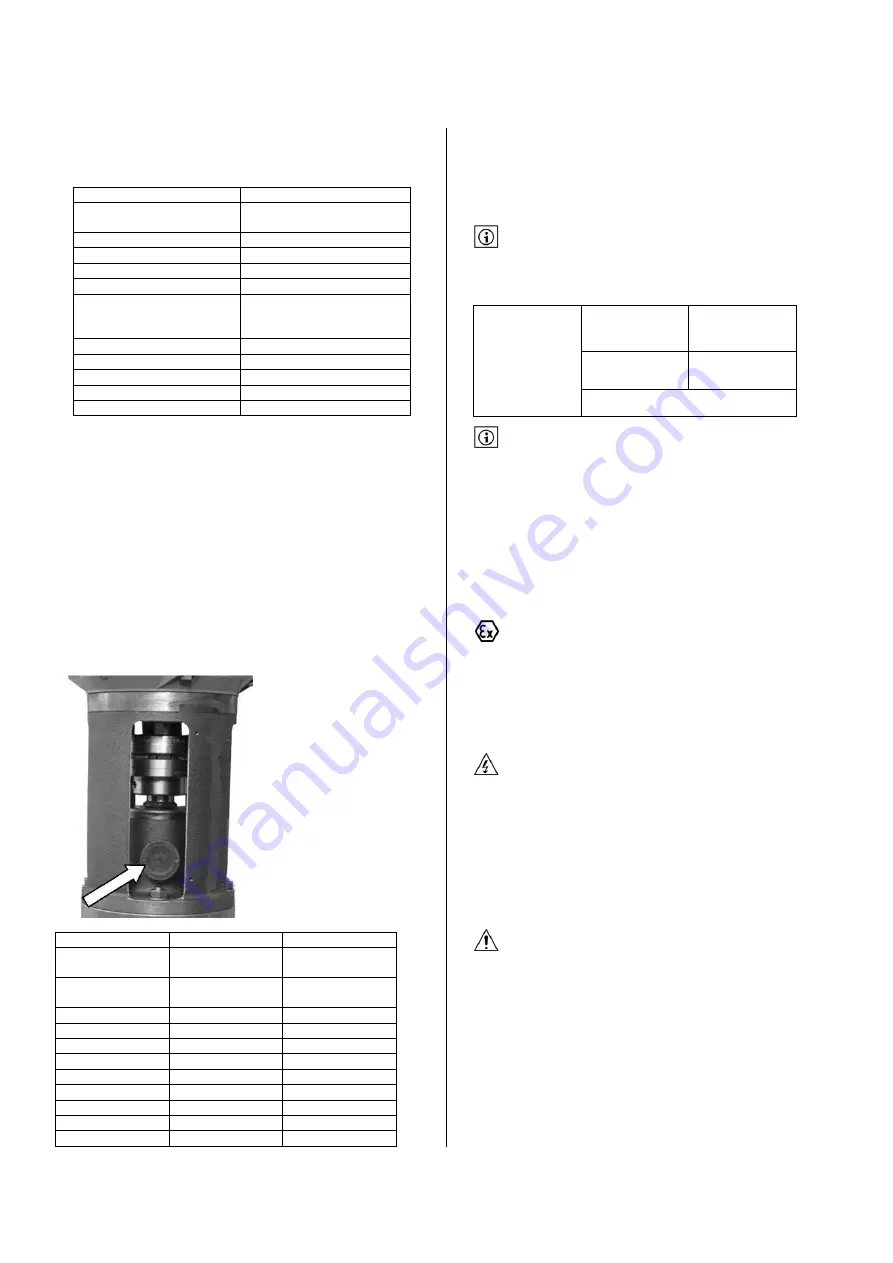

BEARING ASSEMBLY WIT H GREASER

Grease

NLGI2*

NLGI3

Temperature range

-20 to +100°C

(-4 to 212°F)

-20 to +100°C

(-4 to 212°F)

Description acc. To

DIN

KP2K-25

KP3K-20

BP

Energrease LS-EP2

Energrease LS-EP3

Elf

Multis EP2

Multis EP3

Fuchs

RENOLIT EP2

RENOLIT EP3

ESSO

Beacon EP2

Beacon EP3

Mobil

Mobilux EP2

Mobilux EP3

Q8

Rembrandt EP2

Rembrandt EP3

Shell

Alvania EP2

Alvania EP3

Texaco

Multifak EP2

Multifak EP3

SKF

LGEP 2

-

(*) NLGI 2 is a replacement grease and should not be mixed with other

quality of grease.

Grease quantity : 20 cm

3

.

9.2.1.2

LUBRICATION PLAN

First filling is performed in our plant during pump assembly.

Manual greaser must be tightened (1/4 turn) every 1000 hours or every

2 months.

Grease

change

intervals

Light

duty

conditions

n<1500 RPM

Standard or heavy

duty conditions

1500<n<3000 RPM

Every

3500 hours

Every

2500 hours

Or after 12 months

After 10000 operating hours or after 2 years, bearings should be

dismantled, cleaned and filled again with grease. For unfavorable

operating conditions (severely damp, dusty atmosphere or hot service)

greasing intervals may be shortened.

For grease replacement or re-lubrication, high quality lithium soap

grease should be used (eg. Mobilux 2, Esso Unirex N3, …).

9.3

DISMANTING AND RE-ASSEMBLY

9.3.1

DISMANTLING OF MOTOR

Make sure to operate in a safe area.

9.3.1.1

MOTOR ASSEMBLY TYPE CS AND EM

For those two motor assembly types it will be necessary to dismantle the

lineshaft before motor can be removed.

9.3.1.2

MOTOR ASSEMBLY TYPE TM AND TH

Make sure that electric power is disconnected (main power supply

and space-heater power supply). Only trained and qualified maintenance

operators are allowed to open motor junction box.

-

Open motor junction box and disconnect power cables. Disconnect

space heaters electric cable. Refer to motor instructions and

operating manual if necessary.

-

Identify cable connectors with corresponding phases and terminal

connectors in motor junction box. Secure and protect cables ends.

-

Disconnect sensors cables.

Select lifting devices according to the weight of goods to handle.

Motor weight is engraved on its nameplate.

-

Use slings and hooks to handle the motor. Use the lifting eyes or

lifting lugs available on motor frame to lift the motor.

-

Remove motor fastening srews/bolts [6577C].

Summary of Contents for Norma V Series

Page 2: ......

Page 34: ...FRAN AIS 34 13 DECLARATION CE...

Page 35: ...FRAN AIS 35...

Page 36: ...FRAN AIS 36...

Page 68: ...ENGLISH 34 13 EC DECLARATION OF CONFORMITY...

Page 69: ...ENGLISH 35...

Page 70: ...ENGLISH 36...

Page 73: ...5 1 1 1 2 2 1 2 2 WILO 2 3 2 4 2 4 1 25 68 5 C...

Page 74: ...6 2 4 2 2 4 3 2 5 WILO 2 6 2 7...

Page 77: ...9 3 3 1 3 2 3 3 6 WILO 3 4 25 3 4 1...

Page 83: ...15 7 7 1 ATEX 1 5 7 1 1 7 1 2 1 2 3 7 1 3 7 1 4 7 2 7 2 1 7 2 2...

Page 84: ...16 7 2 3 7 2 4 7 3 230 400 400 400 690 690 60079 14 7 3 1 Y 230 400 400 690 7 3 2 U...

Page 85: ...17 7 3 3 U 3 7 3 4 7 4 850 dU dt 2500 ATEX NPSHR NPSHA 40 55 8 8 1 2 1 ATEX...

Page 86: ...18 8 2 8 3 20 30 8 4 mwc HMTmwc Pbar x 100 d x 9 806 d CS ATEX 1 8 5 WILO 9 9 1...

Page 89: ...21 V18 TM TM 2 90 9 3 2 9 3 2 1 9 3 2 2 9 3 2 3 9 3 2 4 TM TH 9 3 2 5 6581 9200 4590A...

Page 98: ...30 2100 7416 M8 5 5 M6 4 7416 3 2 7412 9 3 9 3320 3250...

Page 101: ...33 10 SRV NPSH NPSH NPSH NPSH NPSH...

Page 102: ...34 11 12 12 1 12 2 90 12 3 2 DIN 24296 1 1 1 1 2 1 1 4 1 2 2...

Page 103: ...35 13...

Page 104: ...36...

Page 105: ...37...

Page 106: ...38...

Page 107: ...39...

Page 108: ...40...

Page 111: ......