ENGLISH

16

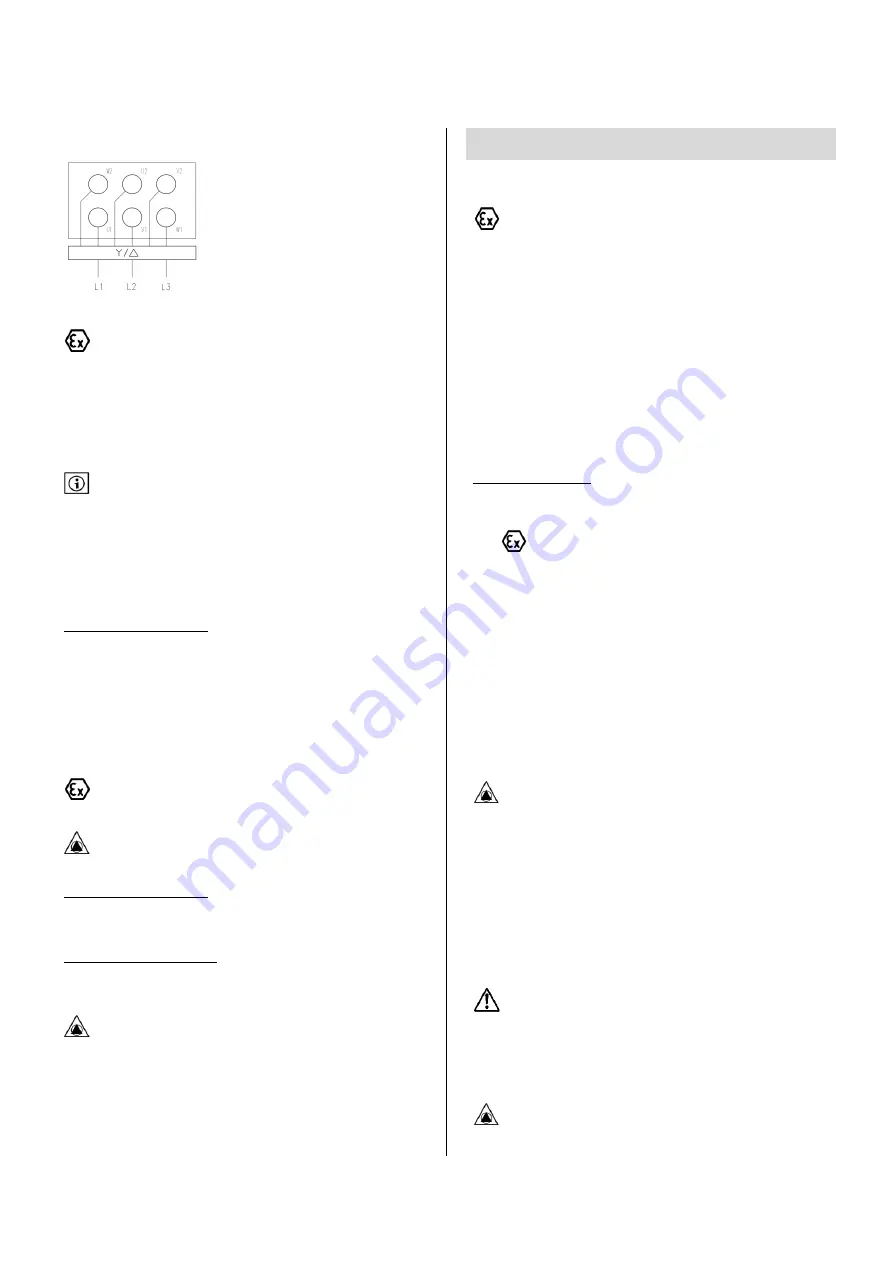

7.3.4

Y /

STARTER :

Grounding of the complete pumpset will be performed with

special care. Earthing will avoid any electrostatic accumulation in

components of the pumpset. Each part of the pumpset should be

connected to earth with a correctly calibrated bonding strap or cable

(motor winding, motor frame, coupling guard, pump baseframe).

7.4

USE OF A FREQUENCY INVERTER

When pump is used with a variable speed drive, make sure that

the frequency inverter instructions and operating manual is available

and known.

The electric motor that is supplied with the pump may be connected

under conditions to a VSD. Variable speed will be used to reach pump

required duty point on site. To ensure a reliable use of the equipment a

few precautions should be taken :

ELECTRICAL REQUIREMENTS :

-

Variable frequency drive will not generate voltage peak higher than

850V (motor phases isolation) and dU/dt values higher than 2500

V/µs (winding isolation). If those values can be reached, a filter

should be installed : ask inverter manufacturer for proper selection

and motor manufacturer for limit values.

-

Choose a vector control inverter or use a quadratic V/F control

inverter.

-

Check that motor nominal voltage is never exceeded.

Power supply cable should comply to ATEX regulation. Ensure that

motor winding is equipped with CTP temperature sensors inside.

A physical barrier should separate power supply cables and low

voltage cables to avoid analog signal distortion.

HYDRAULIC REQUIREMENTS :

-

For all possible speeds, check that the pump NPSH

R

is always lower

than system NPSH

A

.

MECHANICAL REQUIREMENTS :

-

Lower speed should not fall under 40% of pump nominal speed to

avoid any vibrations and an unstable flow.

The harmonic currents that are created by the VSD pass through

motor ball bearings. Standard ball bearings can be used up to 55KW. For

higher installed power (see engraved power on motor name plate), the

motor should be equipped with isolated ball bearings (specific ball

bearing) or with isolated bearing housing (and standard ball bearing).

8

START-UP

8.1

PRE-COMMISSIONING

If the pump is installed in a potentially explosive atmosphere or

when dangerous or polluting fluids are pumped, it is advised (Zone 2) or

requested (zone 1) to install additional protection devices.

Check following points :

-

Pump flow is always higher than authorized continuous minimum

flow,

-

Pump never runs dry,

-

Surface temperature bearings housings is lower than the maximum

admissible surface temperature in selected ATEX zone,

-

Pressure on discharge side of the pump is lower than pump

maximum allowable working pressure.

-

Set alarm and stop trips of sensors.

IN EVERY CASES CHECK :

-

Quality of electrical connections,

-

Protection devices are installed,

-

Auxiliary lubrication piping is connected and running,

-

Flanges connections,

-

Minimum liquid level,

-

Motor direction of rotation is correct,

-

Oil level was checked and greasing of ball bearings has been done,

-

Coupling guard is installed.

8.2

FILLING / VENTING

The volute casing is always submerged. Manual filling is not necessary.

Due to its design, the pump does not need to be vented.

8.3

START-UP

If a barrier fluid, flushing fluid, cooling fluid or a heating fluid is

used, check that auxiliary systems are activated and working correctly

before pump start-up.

Close isolating valve on pump discharge side.

Open all valves in suction line.

Proceed to pump priming (if not already done). Pump casing and

suction pipe should be completely filled with fluid.

Turn the pump on and check discharge pressure increase. Compare

this pressure to the shutoff pressure available on the hydraulic curve

In order to avoid an important overheating of the liquid inside the

pump the pump should not work more than 20 to 30 seconds against a

closed discharge valve.

If expected pressure is reached then progressively open the discharge

valve.

If there is no liquid delivered or if discharge pressure is too low

then see chapter “trouble shooting”.

Summary of Contents for Norma V Series

Page 2: ......

Page 34: ...FRAN AIS 34 13 DECLARATION CE...

Page 35: ...FRAN AIS 35...

Page 36: ...FRAN AIS 36...

Page 68: ...ENGLISH 34 13 EC DECLARATION OF CONFORMITY...

Page 69: ...ENGLISH 35...

Page 70: ...ENGLISH 36...

Page 73: ...5 1 1 1 2 2 1 2 2 WILO 2 3 2 4 2 4 1 25 68 5 C...

Page 74: ...6 2 4 2 2 4 3 2 5 WILO 2 6 2 7...

Page 77: ...9 3 3 1 3 2 3 3 6 WILO 3 4 25 3 4 1...

Page 83: ...15 7 7 1 ATEX 1 5 7 1 1 7 1 2 1 2 3 7 1 3 7 1 4 7 2 7 2 1 7 2 2...

Page 84: ...16 7 2 3 7 2 4 7 3 230 400 400 400 690 690 60079 14 7 3 1 Y 230 400 400 690 7 3 2 U...

Page 85: ...17 7 3 3 U 3 7 3 4 7 4 850 dU dt 2500 ATEX NPSHR NPSHA 40 55 8 8 1 2 1 ATEX...

Page 86: ...18 8 2 8 3 20 30 8 4 mwc HMTmwc Pbar x 100 d x 9 806 d CS ATEX 1 8 5 WILO 9 9 1...

Page 89: ...21 V18 TM TM 2 90 9 3 2 9 3 2 1 9 3 2 2 9 3 2 3 9 3 2 4 TM TH 9 3 2 5 6581 9200 4590A...

Page 98: ...30 2100 7416 M8 5 5 M6 4 7416 3 2 7412 9 3 9 3320 3250...

Page 101: ...33 10 SRV NPSH NPSH NPSH NPSH NPSH...

Page 102: ...34 11 12 12 1 12 2 90 12 3 2 DIN 24296 1 1 1 1 2 1 1 4 1 2 2...

Page 103: ...35 13...

Page 104: ...36...

Page 105: ...37...

Page 106: ...38...

Page 107: ...39...

Page 108: ...40...

Page 111: ......