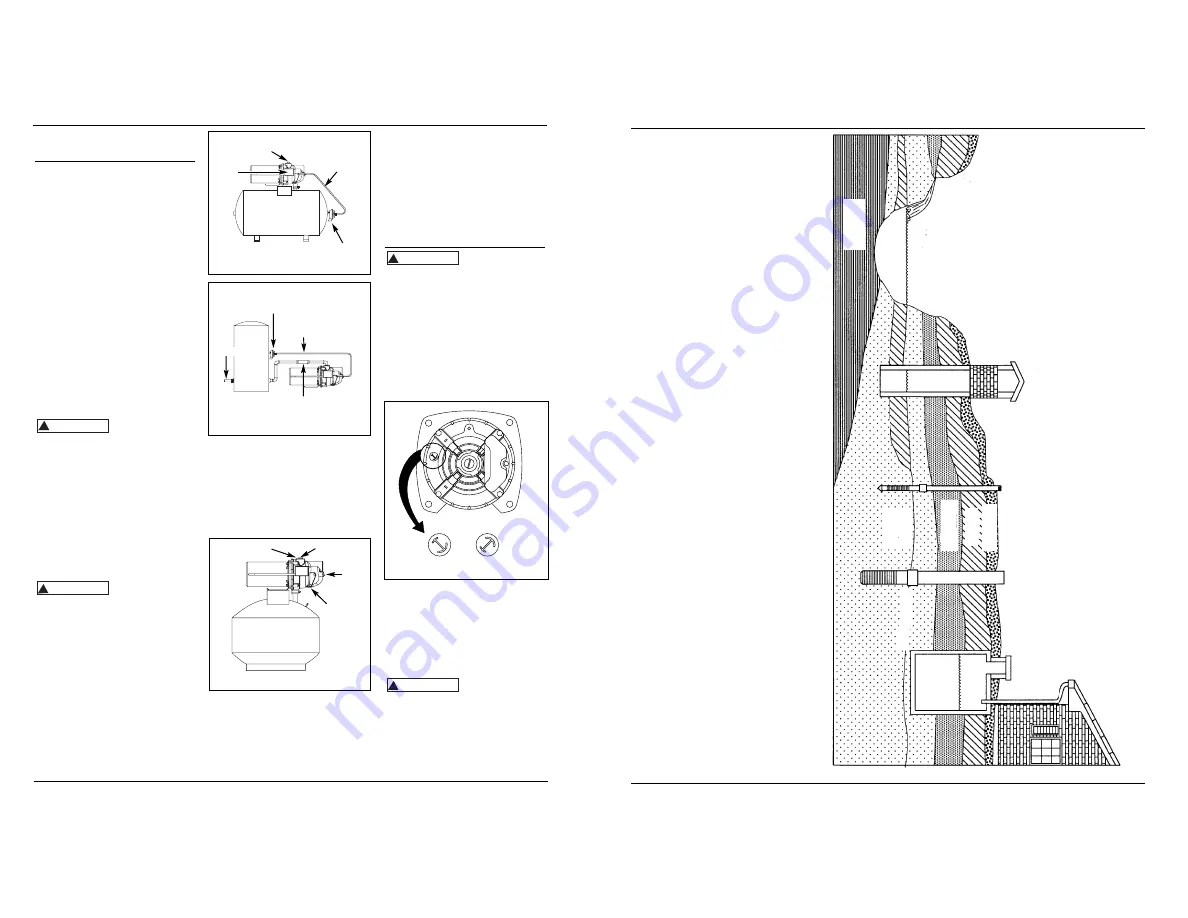

(A) MANANTIAL:

Un manantial que emerge

de la tierra. Ocurre cuando

el agua en materiales

permeables está atrapada

entre materiales

impermeables tales como

roca o arcilla.

(B) LAGO, ARROYO o EST

ANQUE:

Agua superficial, que a menos

que sea tratada, por lo general

no es apta para consumo

humano. Puede ser utilizada

para fines tales como lavado

o irrigación.

(C) POZO EXCA

V

ADO:

Se excava un hoyo de

varios pies de diámetro

hasta una profundidad

basante superficial.

Luego se reviste con

ladrillo, piedra o

concreto para evitar

que se derrumbe.

(D) POZO ACCIONADO:

Se acciona una tubería

con una pantalla con

punta en la tierra, por

debajo de la capa

freática. La profundidad

por lo general es menor

a 15,25 m (50 pies).

Los diámetros comunes

fluctúan entre 2,5 cm (1")

y 5,1 cm (2")

(E) POZO PERFORADO:

Un hoyo perforado en

la tierra con maquinaria y

revestido con tuberías.

Las profundidades

fluctúan entre algunos

pies hasta más de 305 m

(1000 pies). Los diámetros

comunes son 5,1 cm (2"),

7,6 cm (3"), 10,2 cm (4") y

15,2 cm (6") para pozos

de agua de uso doméstico.

(F) CISTERNA:

Un tanque subterráneo

construido para recolectar

agua de lluvias de los

techos. El agua no es

apta para consumo

humano.

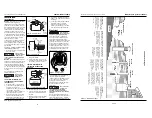

(A) MANANTIAL

(B) LAGO,

ARROYO,

EST

ANQUE

(C) POZO EXCA

V

ADO

(D) POZO

ACCIONADO

(E) POZO

PERFORADO

(F) CISTERNA

MA

TERIAL

PERMEABLE

ARENA

ACUIFERA

CAP

A FREA

TICA

ESQUISTO

TIERRA

SUPERFICIAL

ARCILLA

Suministr

os de Agua

Figura 13 - Suministros de Agua

29 Sp

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

noise transmitted to the house

thrugh the piping.

4. Provide a hose bib (faucet) at the

lowest point in the system to drain

the system for service or storage.

SHALLOW WELL PUMP WITH

PRECHARGED STORAGE TANK

(FIGURE 6)

1. Shut off the power to the pump.

2. Open the faucet nearest the tank

and allow all water to drain from

the tank.

3. Measure the tank precharge at the

valve stem using a tire pressure

gauge.

4

4. If necessary, precharge with an air

pump to 28 - 30 psi on 1/2, 3/4 and 1

HP pumps.

5. Slope the horizontal pipes upward

toward the pump to prevent

trapping air. If the horizontal

distance exceeds 25 feet, see Chart

2 for the recommended pipe size.

Electrical

Risk of electrical

shock. This pump is

designed for indoor installation only.

The voltage of power supply must

match the voltage of the pump. All

above ground well pumps except

SWS50BOOST have dual voltage motors

preset at the factory to 230 volts. The

motors can be converted to 115 volts

by turning the voltage selector to the

desired voltage (See Figure 7). Use a

needle nose pliers to pull the selector

out approximately 1/4”, rotate and

then reinsert in correct position.

Select the proper size wire and fuse

(Chart 3). Time delay fuses are

recommended over standard fuses for

motor circuit protection. All pump

motors have built-in automatic

overload protection that will prevent

damage to the motor due to

overheating.

Do not connect to

electric power

supply until unit is permanently

grounded. Connect ground wire to

approved ground then connect terminal

provided.

A metal underground water pipe or

well casing at least 10 feet long makes

the best ground electrode. If plastic

pipe or insulated fittings are used, run

!

WARNING

!

WARNING

Installation

(Continued)

NOTE:

A packer type foot valve can be

installed in the well (Figure 3,

Illustration B). This type of foot valve

allows the well to be filled with water

when priming and makes the inlet pipe

much easier to test for leaks. Follow

the manufacturer’s instructions when

installing the packer type foot valve.

As an alternative, an in-line check valve

can be used with a driven well (Figure

3, Illustration C). The pipe between the

check valve and the water level will

always be under a vacuum.

Leaking joints or couplings will allow

air to leak into the pipe and cause

abnormal pump operation. Make sure

to use pipe joint compound on all male

pipe threads.

DUG WELL, CISTERN, LAKE AND SPRING

INSTALLATION (FIGURE 12)

1. Install a foot valve on inlet pipe and

lower into water.

The foot valve

should be at least

18” from the bottom of the well or

sand or sediment could be drawn into

the system.

NOTE:

When a lake is used as a water

supply, make sure the inlet pipe is deep

enough to be submerged at all times.

Slope the horizontal piping upward

toward the pump to prevent trapping

air. The pipe must be removed during

winter months or protected against

freezing.

Protect the pipe from damage from

swimmers and boats.

Install a screen

around the inlet

pipe to prevent the entrapment of

swimmers.

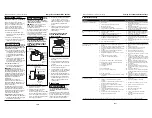

SHALLOW WELL PUMP WITH

CONVENTIONAL STORAGE TANK

(FIGURES 4 & 5)

1. Install air volume control on tank.

2. Connect the copper tube from the

air volume control to the

uppermost 1/8” NPT opening on the

side of pump. Be sure the

connections are tight. Leaking can

cause the pump not to prime.

3. Install a valve and an isolator hose

between the tank and the house

plumbing to aid in pump removal

for servicing and for reducing the

!

WARNING

!

CAUTION

Operating Instructions and Parts Manual

Shallow Well Jet Pump

Figure 4 - Horizontal Tank

Air

Volume

Control

Tubing

Pressure

Switch

Prime

Plug

Air

Volume

Control

Figure 5 - Vertical Tank

Air

Volume

Control

Outlet

Air Volume

Control

Tubing

Hose

Coupling

Figure 6 - Precharged Storage Tank

28-30 psi

3/4 HP & 1 HP

Motor

www.waynewatersystems.com

Outlet

Priming

Plug

Nozzle

Clean

Out

Drain

Fitting

115 V

230 V

115 V

230 V

Figure 7 - Voltage Selector