Para Piezas de Repuestos, Llame al 1-800-237-0987

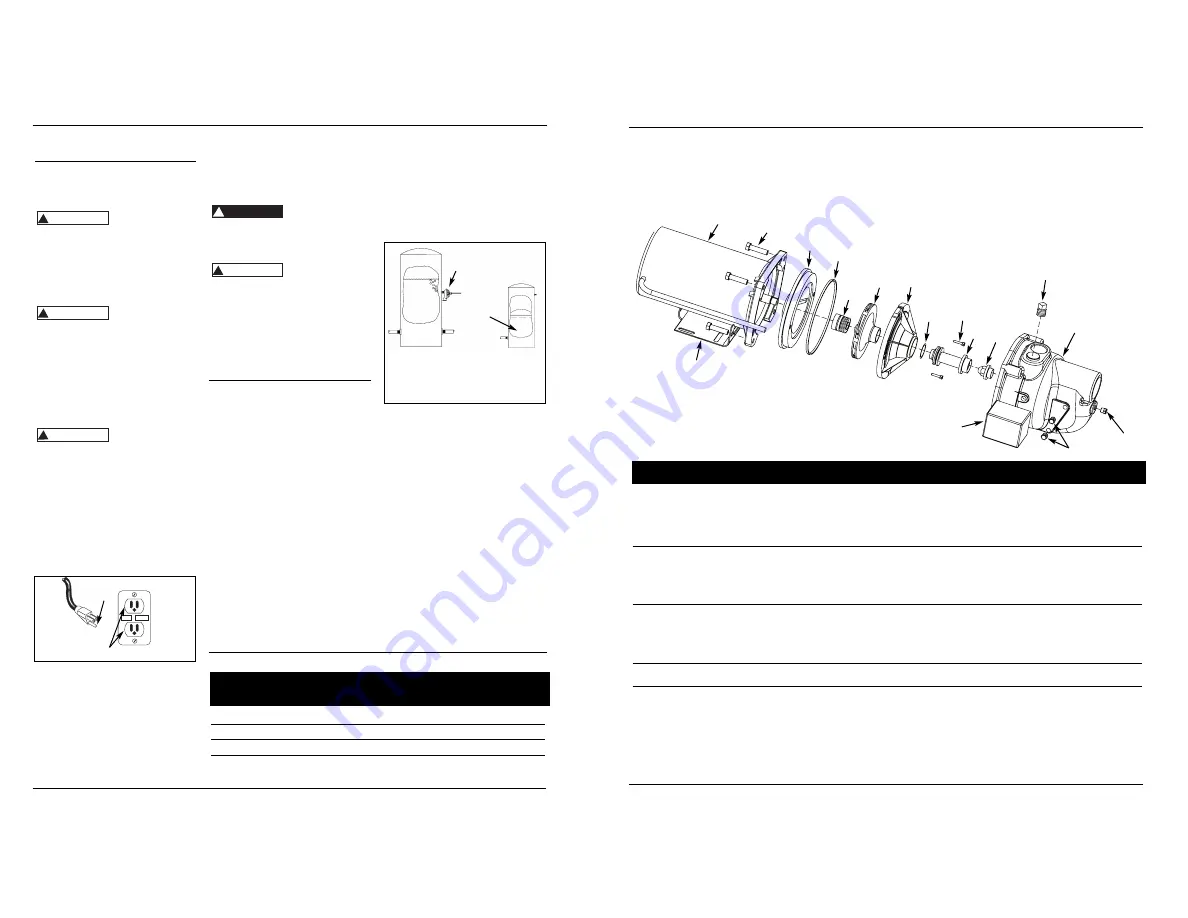

Puede escribirnos a:

Wayne Water Systems

101 Production Drive

Harrison, OH 45030 U.S.A.

31 Sp

Manual de instrucciones de operación y piezas

Modelos para pozos profundos

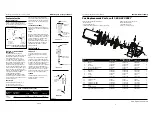

1

Motor

32059-001

34142-001

34142-001

1

2

Tornillo

16636-002

16636-002

16636-002

4

3

Placa de sellado

4372-001

4372-001

4372-001

1

4

• Empaquetadura cuadrada de caucho para anillo

17150-001

17150-001

17150-001

1

5

• Ensamblaje de sello del eje

56393

56393

56393

1

6

Impulsor

23285-021

23285-022

23285-022

1

7

Difusor

17148-021

17148-021

17148-021

1

8

Tornillo

67007-001

67007-001

67007-001

2

9

• Anillo en o

15557

15557

15557

1

10

Venturi

17151-002

17151-003

17151-004

1

11

Boquilla

15672

15672

15672

1

12

19,1 mm (3/4”) Tapón de cebado

15921

15921

15921

1

13

Voluta

56869-001

56869-001

56869-001

1

14

6,4 mm (1/4”) NPT Tapón de cebado

16314-002

16314-002

16314-002

1

15

3,2 mm (1/8”) NPT Tapón de cebado

15766-002

15766-002

15766-002

1

17

Base

23029-021

23029-021

23029-021

1

19

Presostato 30010-021

30010-021

30010-021

1

•

Juego para reparaciones (Incluyes #4, 5 y 9)

56874-001

56874-001

56874-001

1

No. de

Para Los Modelos

Ref.

Descripción

SWS50-1/2 HP

SWS75-3/4 HP

SWS100-1 HP

Ctd.

17

1

2

3

4

5

6

7

8

11

12

10

13

14

16

9

15

Sírvase proporcionar la suguiente información:

- Número de modelo

- Número de serie (si tiene)

- Descripción y número de repuesto como se muestra

en la lista de repuestos

General Safety

Information

(Continued)

16. Do not attempt repairs to the electric

motor. All repairs to the motor must

be completed at a licensed or certified

electrical motor repair shop.

Do not touch an

operating motor.

Modern motors are designed to operate at

high temperatures.

17. Avoid kinking electrical cord and

protect from sharp objects, hot

surfaces, oil and chemicals. Replace

or repair damaged or worn cords

immediately.

Disconnect power

and release all

pressure from the system before

attempting to install, service, relocate or

perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

18. Keep fingers and foreign objects

away from ventilation and other

openings. Do not insert any objects

into the motor.

Risk of electric

shock! Never

connect the green (or green and yellow

wire) to a live terminal!

19. To reduce the risk of electrical

shock, the pump should be plugged

directly into a properly installed and

grounded 3-prong grounding type

receptacle, as shown in Figure 1.

The green (or green and yellow)

conductor in the cord is the

grounding wire. The motor must be

securely and adequately grounded

for protection against shock.

20. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National

Electrical Code, local codes and

ordinances. To ensure a proper

ground, the grounding means must

be tested by a licensed or certified

electrician.

!

WARNING

!

WARNING

!

WARNING

21. Use only 3-wire extension cords that

have a 3-prong, grounding type

plug, and 3-pole receptacles that

accept the equipment plug.

22. Use wire of adequate size to

minimize voltage drop at the motor.

Do not handle

pump or pump

motor with wet hands, when standing

on a wet or damp surface or when

standing in water. Fatal electrical

shock could occur.

Pump motor is

equipped with an

automatic resetting thermal protector and

may restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating pump

at low heads (low discharge restriction),

excessively high or low voltage,

inadequate wiring, incorrect motor

connections or defective motor or pump.

Pre-Installation

WATER SUPPLIES

The water supplies illustrated in Figure

12 are possible sources for water.

These water supplies can be divided

into two categories:

SURFACE WATER

Water from a lake, stream, pond and

cistern. This water is usually not fit for

human consumption, but may be

suitable for washing, irrigation or other

household uses.

GROUND WATER

Water found in the water bearing

stratum at various levels beneath the

earth. Of all the fresh water found on

earth only 3 percent is found on the

surface and 97 percent is underground.

TANKS - CONVENTIONAL STORAGE

The function of the tank is to store a

quantity of water under pressure.

When full, the tank contains

approximately 2/3 water and 1/3

!

WARNING

!

DANGER

2

Operating Instructions and Parts Manual

compressed air. The compressed air

forces the water out of the tank when

a faucet is opened. An air volume

control automatically replaces air lost

or absorbed into the water. The usable

water, or drawdown capacity, of the

tank is approximately 1/6 of the tanks

total volume when operated on a “20-

40” pressure setting (Figure 2).

TANKS - PRECHARGED STORAGE

A precharged storage tank has a

flexible bladder or diaphragm that acts

as a barrier between the compressed

air and water. This barrier prevents the

air from being absorbed into the water

and allows the water to be acted on by

compressed air at initially higher than

atmospheric pressures (precharged).

More usable water is provided than

with a conventional type tank.

Precharged tanks are specified in terms

of a conventional tank. For example, a

20 gallon precharged tank will have

the same usable water or drawdown

capacity as a 40 gallon conventional

tank, but the tank is smaller in size

(Figure 2).

PRESSURE SWITCH

The pressure switch provides for

automatic operation. The pump starts

when pressure drops to a cut-in setting.

Shallow Well Jet Pump

Air Volume

Control

Type

Required

Well X

Precharged

No

PCA

Precharged

No

12P & 30P Horizontal

Conventional

Yes

FX Horizontal

Precharged

No

CHART 1 - JET PUMP/TANK ASSEMBLIES

Air Volume

Control

Bladder

Conventional

Tank

Precharged

Tank

Figure 2 - Conventional & Precharged

Storage Tanks

TEST

RESET

Grounded

Pin

Grounded Outlet

Figure 1

www.waynewatersystems.com