Benchmark Platinum-Edge: Operation-Service Manual

SECTION 7 – BOILER SEQUENCING TECHNOLOGY

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 97 of 146

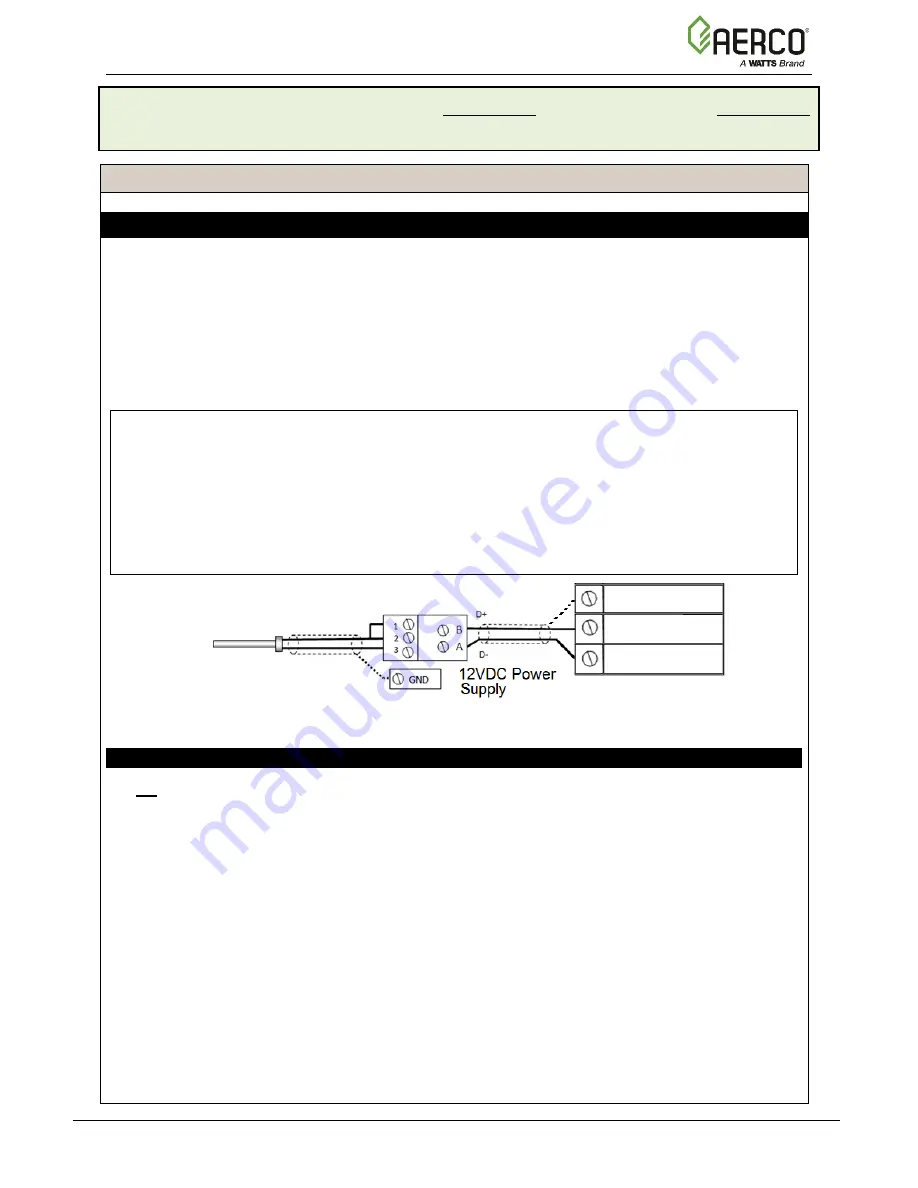

7.3.8 Option 8 Remote Setpoint: MODBUS Header Sensor & MODBUS

Setpoint Drive

OPTION 8

Instructions: Remote Setpoint, Modbus Header Sensor & Modbus Setpoint Drive

Step 1:

MODBUS

HEADER SENSOR WIRING – ANY BOILER

1. Connect the

Modbus Transmitter

(P/N

65169

) terminal

Pin B

to the I/O Board strip

J3

,

terminal

13

(

BST RS485+)

and

Pin A

to terminal

15

(

BST RS485–

) on any of the Boiler

units using Shielded pair 18 - 22 AWG cable.

2. Connect the shield to any

Shield

terminal, such as terminal 3 or 8 on strip

J3

.

2. Connect the

Header Temperature Sensor

(P/N

24410

) to pins 2 and 3 of the

Modbus

Transmitter

using Shielded pair 18 - 22 AWG cable.

3. Install a jumper wire between pins 1 and 2 of the

Modbus Transmitter

.

NOTES:

•

Polarity must be observed for the RS485 connections.

•

Ground the shield to any

Shield

terminal on the I/O Board (such as Terminal 3).

•

The header sensor must be installed between 2 and 10 feet (0.61 and 3.1m)

downstream of the LAST boiler in the plant’s supply water header.

•

There is no polarity to be observed. The ground for the shield is at the power supply

ground. The sensor end of the shield must be left free and ungrounded.

Step 3: OPTION 8 CONFIGURATION

On All Boiler:

1. Go to:

Main Menu

Advanced Setup

BST Cascade

Cascade Configuration

:

•

Set the

Unit Mode

parameter to

BST Client

.

2. Go to:

Main Menu

Advanced Setup

BST Cascade

Application Configuration

:

•

Set the

Unit Address

parameter to the communication address of the unit.

Continued on next page

MODBUS TRANSMITTER

15 BST RS485–

HEADER TEMP SENSOR

(P/N

24410)

13 BST RS485+

3 Shield

I/O BOARD STRIP J3