Benchmark Platinum-Edge: Operation-Service Manual

SECTION 8 – MAINTENANCE

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 104 of 146

Lean O

2

Sensor Maintenance Instructions

1. Set the ON/OFF switch on the Edge Controller to the

OFF

position.

2. Remove the top shroud from the unit by grasping the top handle and lifting straight up. This

will disengage the shroud from the four (4) pins in the side panels.

3. Disconnect the O

2

sensor lead wire by pushing in on the release tab and pulling apart the

connector.

4. Next, loosen and remove the O

2

sensor and crush washer from the burner plate using a

15/16" open-end wrench.

5. Thoroughly inspect the O

2

sensor. If eroded, the sensor should be replaced. Otherwise

clean the sensor with a fine emery cloth.

6. Reinstall the O

2

sensor and crush washer on the burner plate.

7. Reconnect the sensor lead wire.

8. Reinstall the shroud on the unit.

NOTE:

If the AERtrim technology system is functioning, it should be inspected at the same time as

O

2

sensor maintenance. For instructions see Section 9:

AERtrim Operation

in this guide.

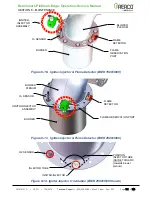

8.5.1 Air Eductor Air Pump Maintenance – BMK 5000 & 6000

Benchmark Platinum 5000 and 6000 units contain an Air Eductor assembly, mounted just inside

the O

2

Sensor Cover on the unit’s back panel, (see Figure 8-3b, above). It includes an air pump,

which draws an air sample from the combustion chamber past the O

2

Sensor, ensuring its

accuracy.

The air pump contains an air pump filter (P/N

87008

) should be

inspected-cleaned

every 12

months and

replaced

every 24 months. It is included in all BMK 5000 & 6000 24 Month

Maintenance Kits.

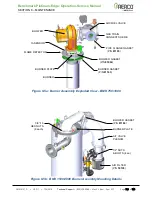

Air Pump Maintenance and Troubleshooting Instructions

1. Remove the Air Pump’s plastic air filter cover and clean or replace the air filter (see Figure

8-4, below).

2. If the Air Eductor or the Air Pump is not operating properly, try the following troubleshooting

steps:

a) Check the connector to the Air Pump for corrosion or contamination, clean as

needed.

b) If the Air Pump is not running, check 120 VAC power to the Air Pump. If 120 VAC

power is OK, replace the Air Pump.

c) If the Air Pump is running, check current drawn in series with one power wire. If the

current is within the range of 0.1 to 0.6 amps, the Air Pump is operating properly.

d) Check the signal from current sensor. If it is within the range of 0.20 to 1.20 VDC,

there may be a connector problem or IGST board issue. Check all connectors and

wires first. Try swapping IGST board with known good board before ordering a new

one.