Benchmark Platinum-Edge: Operation-Service Manual

SECTION 7 – BOILER SEQUENCING TECHNOLOGY

OMM-0137_D • GF-211

•

7/16/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 89 of 146

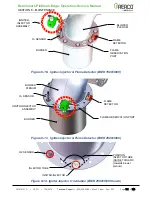

7.3.4 Option 4 Outdoor Reset: Modbus Header Sensor & Modbus

Outdoor Sensor

OPTION 4

Instructions: Outdoor Reset, Modbus Header Sensor & Modbus Outdoor Sensor

NOTE:

Both Header Sensor AND Outdoor Sensor must be wired. See the

Edge Controller Manual

and (OMM-0139, GF-213) for more information.

St

ep 1: HEADER SENSOR WIRING – ANY BOILER

1. Connect the

Modbus Transmitter

(P/N

65169

) terminal

Pin B

to the I/O Board strip

J3

,

terminal

13

(

BST RS485+)

and

Pin A

to terminal

15

(

BST RS485–

) on any of the Boiler

units using Shielded pair 18 - 22 AWG cable.

2. Using Shielded pair 18 - 22 AWG cable, connect the

Header Temperature Sensor

(P/N

24410

) to pins 2 and 3 of the

Modbus Transmitter

.

3. Install a jumper wire between pins 1 and 2 of the

Modbus Transmitter

.

NOTES:

•

Polarity must be observed for the RS485 connections.

•

Ground the shield to any

Shield

terminal on the I/O Board, such as Terminal 3 or 8.

•

The Header Sensor must be installed between 2 and 10 feet (0.61 and 3.1m)

downstream of the LAST boiler in the plant’s supply water header.

•

There is no polarity to be observed. The ground for the shield is at the power supply

ground. The sensor end of the shield must be left free and ungrounded.

Step 2: OUTDOOR SENSOR WIRING

1. If you have not already done so, complete step 1 of the instructions above to connect the

Modbus Transmitter

to the I/O Board.

2. Connect the

Outdoor Temperature Sensor

(P/N

61048

) to

Pins 5

and

6

of the

Modbus

Transmitter

using a Shielded pair 18 - 22 AWG cable.

3. Install a jumper wire between

Pins 4

and

5

on the

Modbus Transmitter

.

MODBUS TRANSMITTER

15 BST RS485–

HEADER TEMP SENSOR

(P/N

24410)

13 BST RS485+

3 Shield

I/O BOARD STRIP J3

15 BST RS485–

13 BST RS485+

3 Shield

MODBUS TRANSMITTER

OUTDOOR TEMP SENSOR

(P/N

61048)

I/O BOARD STRIP J3