26

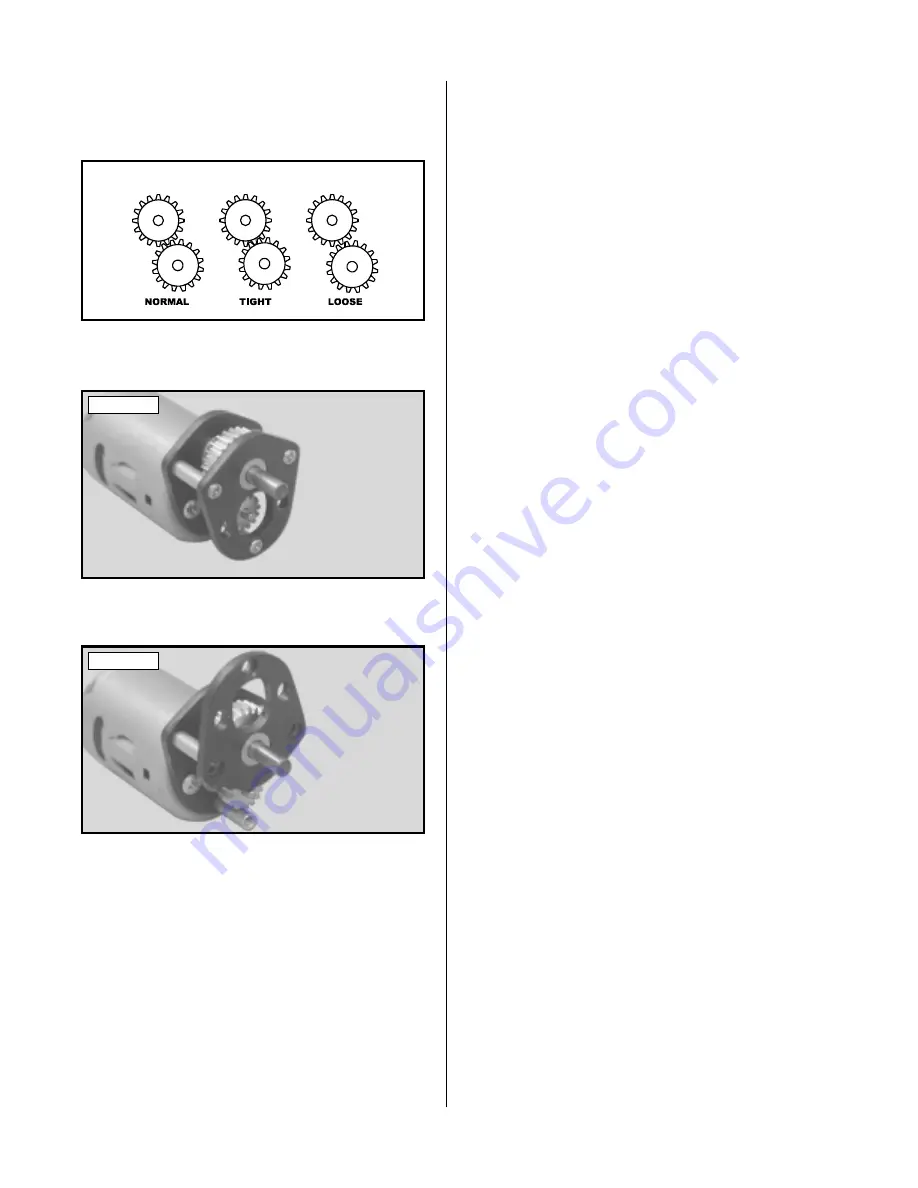

gears. If the gears are too tight, it will cause excessive

strain on the gear box and motor. If they are too loose,

they will probably strip out after a short period of time.

See figure # 12 below.

Figure # 12

❑

8) To adjust the gear mesh, use a # 1 phillips screw-

driver to remove the three screws holding the front gear

box plate in place.

See photo # 38 below.

❑

9) Rotate the plate up and out of the way and loosen

the two machine screws that secure the gear box to the

motor.

See photo # 39 below.

❑

10) Once the screws are loosened you can adjust

the height of the gear box assembly. When you are satis-

fied with the alignment, tighten the two screws securely

and reinstall the front gear box plate.

❑

11) Double check the gear mesh. If you are satis-

fied that it is correct, apply a couple of drops of Trinity

bushing oil onto the gear box bearings. Also apply a light

coating of grease to the gears and rotate the prop shaft a

couple of times to distribute the oil and grease.

❑

12) Remove any excess oil using a paper towel and

reinstall the motor. Connect the motor leads to the ESC

and reinstall the cowling, propeller and spinner assembly.

Photo # 38

Photo # 39