16

☛

If the servo arm has more than four holes in it, it may

hit the side of the fuselage when it's installed. If that's the

case, use a modeling knife to cut the arm shorter.

❑

11) With both the servo horn and the elevator cen-

tered, use a pen and draw a mark on the pushrod wire

where it crosses the third hole out from the center of the

servo horn.

See photo # 23 below.

❑

12) Using Magnum Z-Bend Pliers, make a Z-bend

in the pushrod wire at the mark you drew. Use wire cut-

ters to remove the excess wire.

❑

13) Connect the servo arm to the Z-bend and attach

the servo horn to the servo output shaft, making sure that

the servo horn is centered. When satisfied with the align-

ment, install and tighten the servo horn retaining screw,

provided with your servo, to secure the servo horn into

place.

See photo # 24 below.

Photo # 23

Photo # 24

❑

14) Remove the masking tape from the elevator and

double check that both the elevator and the elevator servo

are still centered.

☛

To adjust the center-trim of the elevator, use a pair of

pliers to carefully open or close the "V" in the pushrod

wire. Doing this will effectively lengthen or shorten the

pushrod wire.

ADJUSTING THE ELEVATOR PUSHROD

❑

15) With your radio system plugged in and turned

on, check the direction the elevator control surface moves

and the amount of control deflection. To do this pull back

on the elevator control stick. The elevator should move

up. If it does not, flip the servo reversing switch on your

transmitter to change the direction.

❑

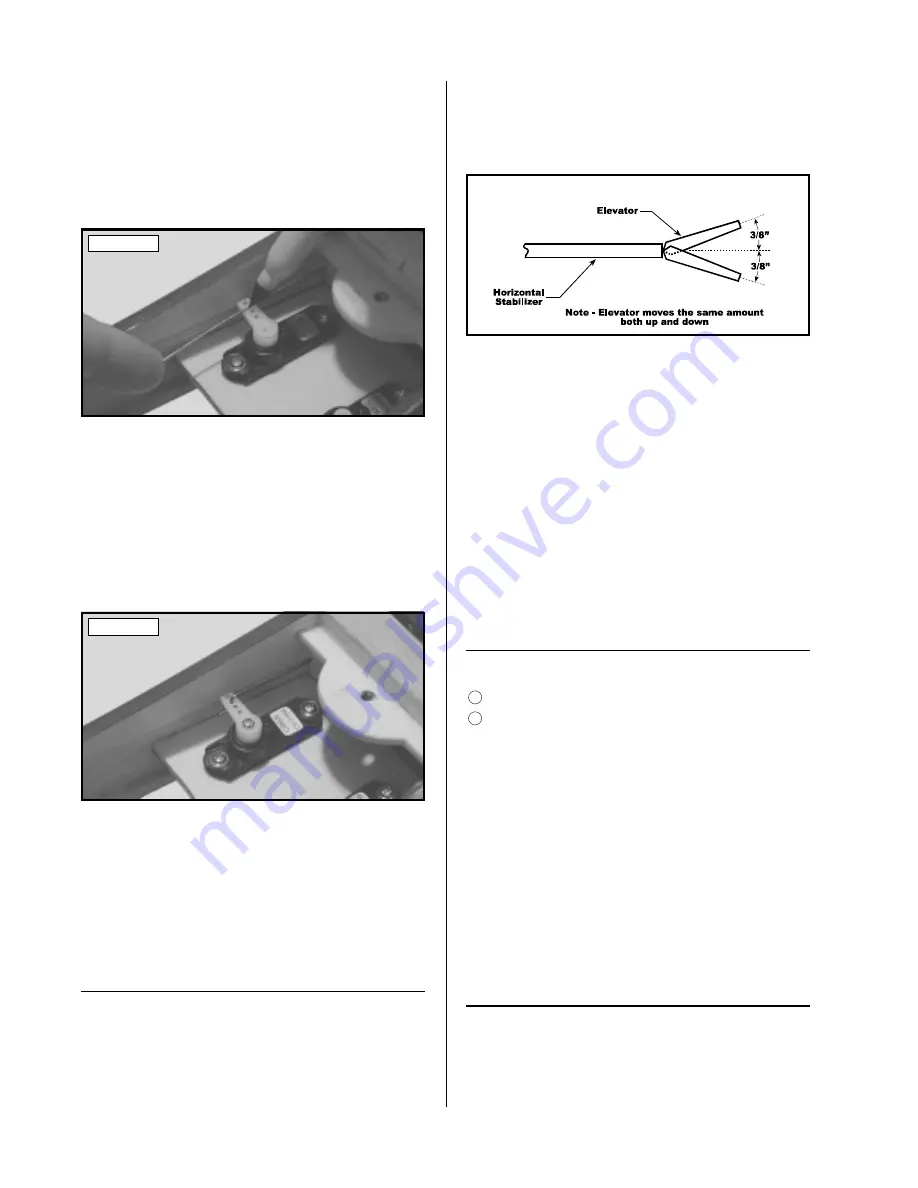

16) Pull back completely on the elevator control stick.

While holding the control stick completely back, use a ruler

and measure the amount the trailing edge of the elevator

moves up. This measurement should be 3/8" measured at

the widest point of the elevator.

See figure # 7 below.

Figure # 7

❑

17) If the control surface deflection is more or less

than 3/8" it must be changed. If your radio is equipped

with End Point Adjustments (EPA), make those adjust-

ments using the transmitter. (Refer to your radio guide

for further details.) If your radio does not have this fea-

ture, you can still make the adjustments to the pushrod

manually.

❑

18) If the elevator is moving

more

than 3/8", move

the Z-bend in one hole toward the center of the servo horn

to decrease the control deflection. If the elevator is mov-

ing

less

than 3/8", move the Z-bend one hole out from the

center of the servo horn to increase the control deflection.

When adjusted properly, the elevator should move 3/8"

both up and down.

PARTS REQUIRED

TOOLS AND SUPPLIES REQUIRED

RUDDER PUSHROD

❑

Kwik Bond Thick C/A

❑

# 0 Phillips Head Screwdriver

❑

Excel Modeling Knife

❑

Needle Nose Pliers

❑

Wire Cutters

❑

Magnum Z-Bend Pliers

❑

Straight Edge Ruler

❑

Pen or Pencil

❑

Masking Tape

❑

{1} 1mm x 420mm Pushrod Wire

❑

{1} Control Horn

5

7

INSTALLING THE RUDDER

PUSHROD AND CONTROL HORN

❑

1) Using Magnum Z-Bend Pliers, make a Z-bend

in only one end of the 1mm x 420mm pushrod wire. Use

wire cutters to remove any excess wire, leaving about 3/16"

of wire beyond the Z-bend.