3.2.7. On/Off/Stand-by Positions

The boiler panel does not have ON/OFF button. The boiler must be

turned on/off by using the V circuit breaker to be connected to the

boiler circuit.

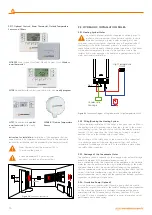

3.2.8. Operation in Winter Mode

When the boiler is in this position, it operates both for heating the

ambient (if a boiler is fitted) and producing domestic hot water.

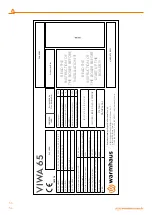

Heating system temperature setting set with no (3) and (4) buttons in

When

symbol is displayed, keep

MODE button pushed.

Release the button when cycle is

completed.

An analogue manometer is placed near lower-right side of

the boiler. System pressure can be read from this manometer

even when there is no power.

{If you have an underfloor heating system, the temperature

adjustable by the Heating temperature setting buttons (3)

will be limited to the maximum temperature value (e.g.

Maximum 47 °C) as your boiler will have been set to “Low

Temperature Operation” by the Authorized Service}

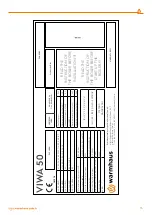

Flame modulation symbol appears on middle part of the display when

boiler starts operating. In this mode, you can adjust the temperature

with temperature setting buttons (see Figure 42) temperature can be

increased with (3)

and reduced with (4)

set between 35

–80 °C, when these buttons are pushed, background light turns on and

°C symbol and

symbol blinks next to the temperature value.

In this case the boiler switches to Heating

mode,

symbol blinks at lower-left part

of the display, and

tap symbol appears

on the display (if a boiler is fitted). In this

mode, a digital manometer appears at

lower-middle of the display, and

Current heating system temperature is

displayed simultaneously, then background

light turns off

A cycle appears on the display.

Figure 42, and Hot Domestic Water temperature is set with no (7) and

(8) buttons, and this temperature is shown on this display with no (10)

indicator for Heating system and no (12) indicator for Hot Domestic

Water.

Turning off the Boiler

To turn off the boiler while operating in SUMMER mode;

Hot Domestic Water Setting in Winter

Mode (If a boiler is set;

); In this mode,

you can set the Hot Domestic Water

temperature with (7) and (8) no buttons

under the

RESET

button on

symbol

side between 35 – 60 °C. Background light

turns on while changing the temperature,

°C symbol and

symbol blinks next to

the HDW temperature value. Background

light turns off after setting.

When starting the boiler for the first time,

keep

MODE

button pushed until the cycle

on the display is completed, the

boiler will first switch to Heating mode,

symbol will blink on the lower-left

part of the display, and current heating

system temperature will appear on the

display, then background light will turn off.

Push

MODE

button again to switch to

domestic water mode, then release the button

when the cycle on the display is completed.

In this mode, the

symbol will blink on the

lower-right corner of the display, and current

domestic water temperature will appear on

the display, then the background light will

turn off. When you are going to switch to the

summer mode from winter mode, push

MODE

button, and The boiler will be in

Summer

mode when

cycle is completed.

When

MODE

button is pushed, the

background light will be on until

the

cycle is completed, the background light

turns off when

symbol appears on

the display, and now your combi boiler is

in

OFF

mode

In this mode, you can set the hot domestic

water temperature with no (7)

and (8)

buttons under the RESET button (the

side with

symbol) between 35 – 60 °C.

Background light turns on while changing

the temperature, °C symbol and

symbol

blinks next to the HDW temperature value.

Setting value will be confirmed when

background light turns of after setting

24