Error

Code

Error

Fault

Possible Cause

Solution(s)

E 01

Exhaust gas Thermostat (boiler

with open combustion) intervention

The boiler does not operate,

E01 error code blinks

> Exhaust gas sensor fault

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

E 02

Water pressure in the system is

low/system parameters are set

incorrectly

The boiler does not operate,

E02 error code blinks

> Water pressure in the

boiler is not sufficient

> TsP parameter is set

incorrectly

1-) Fill the boiler up to 1,2-1,5 bar as specified in the manual,

the problem will be automatically solved.

2-) Check if the system pressure is 1,2-1,5 bar from the

manometer on the lower right side of the boiler

3-) Call Authorized service if the fault remains unsolved

4-) Restart the boiler by pushing RESET button.

E 03

High water pressure in the system

The boiler does not operate,

E01 error code blinks

>Water pressure in the

system is higher than 3,8

bars

1-) Drain the boiler down to 1,2-1,5 bar as specified in the

manual, the problem will be automatically solved

2-) Check if the system pressure is 1,2-1,5 bar from the

manometer on the lower right side of the boiler

3-) Call Authorized service if the fault remains unsolved.

4-) Restart the boiler by pushing RESET button.

E 04

Hot Domestic Water temperature

sensor is faulty

The boiler does not operate

in Hot Domestic Water mode,

but operate in Heating system

mode, E04 Error Code blinks

on the display

> Hot Domestic Water

temperature sensor is

faulty

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

E 05

Heating system supply

temperature sensor is faulty

The boiler does not operate,

E05 error code blinks

> Heating system supply

temperature sensor is

faulty

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

E 06

No ignition

The boiler does not operate,

E06 error code blinks

> Gas Supply fault

1-) First restart the boiler by pushing RESET button, and check

if problem is solved

2-) Check if other appliances burning gas are operating.

3-) Check if the main gas valve is open.

4-) Check if the boiler gas valve under the boiler is open.

5-) Restart the boiler by pushing RESET button, and check if

problem is solved.

6-) Call the authorized service if not solved.

E 07

Safety Thermostat intervention

The boiler does not operate,

E07 error code blinks

> Insufficient water in the

system

> Pump clogging

> Pump Failure

> Pump Equipment

clogging

1-) First restart the boiler by pushing RESET button, and check

if problem is solved

2-) Check if the boiler heating system valves are open, if not,

open all of them.

3-) Check if all radiator valves are open, if not open, minimum

3 meter-radiators must be on.

4-) Restart the boiler by pushing RESET button, and check if

problem is solved.

5-) Call the authorized service if not solved.

E 08

Flame circuit fault

False flame signal from burner

or electrode

> Wearing or corrosion of

electrode

> Electrode position

> Interruption on cable

> Water clogging in water

flow pipe

> Electronic card

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

E 09

No water circulation in the system

The boiler does not operate,

E09 error code blinks

> Insufficient water in the

system,

> Pump clogging,

> Pump Failure,

> Pump Equipment

clogging

1-) Restart the boiler by pushing RESET button, and check if

problem is solved.

2-) Check if the boiler heating system valves are open, if not,

open all of them.

3-) Check if all radiator valves are open, if not open, minimum

3 meter-radiators must be on

4-) Restart the boiler by pushing RESET button and check if

the problem is solved

E 10

Heating temperature RETURN

sensor is faulty

The boiler does not operate,

E10 error code blinks

> Heating system RETURN

temperature sensor is

faulty

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

E 11

Gas valve modulator is not

connected

The boiler does not operate,

E11 error code blinks

> Gas valve line

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

E 12

Hot Domestic Water temperature

fault in summer mode

The boiler does not operate,

E12 error code blinks

> Hot Domestic Water

temperature sensor in the

boiler is faulty

1-) Restart the boiler by pushing RESET button.

2-) Call the authorized service if fault remains unsolved.

(P40) Heating ignition delay time.

The boiler appliance is equipped with an electronic timer in order to

prevent frequent ignition of the boiler. This time is set as 2 minutes as

default, and it can be extended up to 10 minutes.

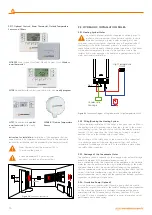

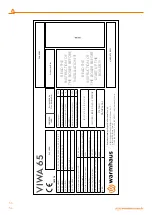

(P42) Ready Hot Water (Preheat enabled/disabled).

This function heats up the boiler and keep water hot in order to

prepare your Hot Domestic Water request immediately as well as to

reduce cold water consumption while waiting. This function can be

enable or disable on 6-button Viwa 50 &

Viwa 65 models. Preheat function is enabled when hot water

temperature increasing RESET button is pushed until the cycle is

completed. Pre-On or Pre-Off is displayed on the LCD display for 5

seconds at the end of this time.

Activation of this function in Viwa 50 & Viwa 65 models is carried out

by our Authorized Service with parameter setting upon your request.

26