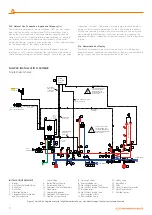

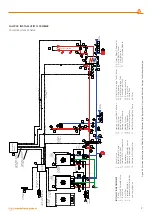

Figure 13

Hermetic vertical split flue connection.

Figure 11

Hermetic concentric and vertical split

flue connection.

Figure 12

Vertical Type Hermetic Use with

Split Flue Set

Figure 14

Building chimney connection with hermetic split flue

Figure 15

Use with split flue set

C

33

C

53

C

53

C

83

C

Discharge with homocentric flue connection

Discharge to building chimney and fresh

air intake with split flue connection

For room sealed appliances of the type C8 boilers

a) overheat combustion products temperature; < 105 C°

b) CO2-content; 9.00 % ( tol%0,5 / -0,5 % )

c) characteristics of the chimney to which the

boiler may be connected, according to fig 13.

d) condensate flow into the appliance is not allowed.

Exhaust gas discharge through the building chimney and fresh

intake from outside with split flue sets

For room sealed appliances of the type C6 boilers

overheat combustion products temperature for flue; < 105 °C

CO

2

content at nominal operating conditions; 9.00 % (tolerance

+%0,5 / -0,5 % ) maximum allowable draught and maximum

allowable pressure difference between combustion air inlet and

flue gas outlet (including wind pressures); 120 Pa. characteristics

and the applications of the duct system to which the boiler

can be connected; condensate flow into the appliance is not

allowed. Maximum allowable temperature of combustion air;

40 C° maximum allowable recirculation rate of 10 % under wind

conditions.

Attention:

The terminals for the supply of combustion air and for

the evacuation of combustion products shall not be installed on

opposite walls of the building.

Exhaust gas discharge through the

building chimney and fresh intake

from outside with split flue sets

Exhaust gas discharge and fresh air intake

with concentric flue kit and split flue kits

For room sealed appliances of the type C5 boilers

Attention:

The terminals for the supply of combustion

air and for the evacuation of combustion products

shall not be installed on opposite walls of the building.

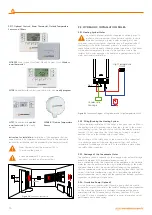

Exhaust Gas Discharge Fresh Air

Intake with Split Flue Sets

Air

Exhaust Gas

B

2

3

C

13

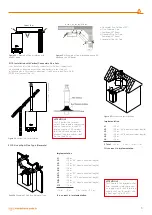

Figure 10

Hermetic (Concentric) and Flue

(Split-Flue type

2.1.10. Peripheral Distances of the Flue Outlet Connections

For positioning of the flue set outlet pipe, see Figure 16. The flue shall

be installed in accordance with the national and local regulations.

No part of the outlet pipe or connections shall be blocked. If the

outlet pipe passes1000 mm nearby of a plastic or painted groove or

500 mm of painted fringes, an aluminum shield with at least 1000mm

length shall be placed below the groove or fringe. Outlet pipe shall

be at least 2 m over surfaces within reach by individuals. Under certain

weather conditions, outlet pipe may emit water vapor; installation shall

not be performed at places where this vapor may cause discomfort.

Exhaust gases shall be prevented from entering flue ventilation spaces.

Flue system of combi may be installed from inside the room without

requiring intervention from the external wall. For that reason, an

enclosure shall be installed in the wall for lining the internal surface of

channel wherein the outlet pipe passes through the wall, particularly

for thick walls.

2.1.11. Installation with (Ø80/125 mm) horizontal homocentric flue

sets Connection of (Ø80/125 mm) horizontal homocentric flue set

to the boiler

Since your boiler is a hermetic model, it takes the used air from outside and

discharges exhaust gases created as the result of burning through the same

flue group. In order to prevent emission of extremely harmful exhaust gases,

flue usage and installation is very important, therefore warnings should be

taken into consideration when flue connections are being performed.

• Carry out required flue selection for the external flue connection. If

the standard flue set is not adequate, please select most suitable

components from our list of connection accessories considering

warnings given in our user guide.

Select the most suitable components by also considering our

warnings.

• Fix the flange under the Bend piece (1) by using the Flange Bolt (10)

Flange Connection Screws (11) to holes on the boiler.

(10) secure it with Flange Connection Screws (11) onto the holes on

the boiler.

10