2. INSTALLATION PERSONNEL SECTION

2.1. BOILER INSTALLATION RULES

2.1.1. General Rules for Installatıon Place of the Boiler

There are not any ventilation limitations for areas where hermetic

(C type) boiler is to be installed (it can be installed independent of

the volume and ventilation of the room). It can also be installed in

protected areas like balcony and terrace provided that it is placed in a

protective closure and that precautions against freezing of the system

water are taken. The boiler shall be securely mounted to the building

wall. A flexible joint shall be used between the boiler and gas line.

Lengths of the flex ducts to be used in Type A, B and C appliances

shall not exceed the values permitted by the local gas authority. Flue

outlets of hermetic boilers must be connected to the areas which

are directly open to outside area, and have sufficient air circulation.

Conditions of exhaust gas system gas outlets of these appliances

(position of the pipe outlets in various forms, vertical, horizontal

minimum distances, cross-sectional areas of ducts if used, etc.) shall be

in compliance with TS 12514 standard.

2.1.2. Places where hermetic boilers cannot be installed

• Stairwells of buildings,

• common aisles, ventilation ducts, garret, attics, emergency exit doors,

storage rooms and other similar common areas,

• Yards between buildings,

• Narrow gaps between eaves

• On the chimney walls,

• Closed balconies,

• Open balconies (except placed in an enclosure and permitted by

the manufacturer),

• Under the extending structures hindering outlet of exhaust gas,

• Places exposed to direct wind force,

• Openings supplying fresh air to other units (C type) It is forbidden to

install hermetic boilers at places specified above!

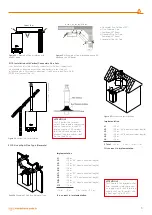

2.1.3. Mounting of the Boiler to Wall and Selection of Installation

Place

• Mounting of the boiler to wall must be checked and ensured to be

stable and safe.

• The hanger plate and connection screws supplied with the boiler

shall be mounted on a filled or semi-filled brick wall in accordance

with the installation scheme, and shall not be used for other

purposes.

• In case any different materials are used for mounting, the warranty

of the boiler shall be terminated.

• If the wall to which the boiler is to be mounter is not brick, strength

of the support system shall be checked.

• The boiler shall be mounted on a fire resistant wall.

• The boiler should be mounted so as the height of the hanger plate

to be between 1,8-2,2 mm from the ground.

• The boiler shall be mounted with gaps as minimum 30 cm above

the ground, minimum 5 cm from both sides and minimum 90 cm

from the front side where the installation area is limited, for allowing

easy intervention of the service technician.

• The boiler shall not be installed in areas which contain or may

contain explosives, flammables and acid vapors.

• It shall not be installed next to or above ovens, cookers, radiators or

heaters.

• Hermetic boilers can also be installed in cabinets, provided that

minimum 5 cm from each side is left.

• If the boiler is to be mounted over the kitchen countertop or

kitchen set, there shall be a minimum 50 cm distance under the

boiler.

• Due to possibility of water draining from the Safety Valve of the

boiler after mounting, the outlet shall be connected to the drainage

line. If this is not possible; do not place electronic appliances, and

tools, parts and materials which may breakdown, be deformed or

form rust.

• Any furniture should not be placed under the boiler due to the

reasons specified above.

• Make sure that there are no liquids or inflammable materials in the

immediate vicinity of the boiler.

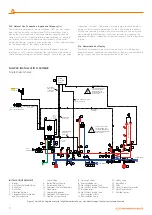

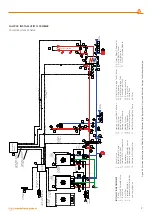

Figure 6

Viwa 50 / Viwa 65 boiler dimensions and connections

Warmhaus Viwa 50 / 65

1) 230 V AC Main Power Supply

2) Manometer

3) Safety Valve Drainage Line

4) Gas Inlet Line

5) Heating Supply Line

6) Heating Return Line

7) Condensate Drainage Line

8) Sediment-Air Separator Discharge

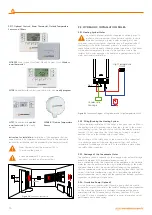

9) Heating/Domestic Hot Water MODE

Button

10) Heating Temperature Increasing

Setting Button,

11) Heating Temperature Reducing

Setting Button

12) LCD Display

13) Service Port

14) RESET Button

15) Domestic Hot Water Temperature

Increasing Setting Button

16) Domestic Hot Water Temperature

Reducing Setting Button

17) Exhaust gas/Flue outlet

18) Hanger plate

70

0

4

158

7

65

207

124

127

207

127

725

30

385

420

40

100

121,5

105,5

90

88,5

136

MODE

RESET

+

-

-

+

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

18

Kalorifer Gidiş

G1 1/4

Kalorifer Dönüş

G1 1/4

GAZ

G 3/4

1

2

9

8

7

6

5

4

3

10

11

12

13

14

15

16

17

230V AC MAIN SUPLLY

MANOMETER

PRESSURE RELIEF VALVE OUTLET

GAS INLET

CENTRAL HEATING FLOW (CH)

CENTRAL HEATING RETURN (CH)

CONDANSATE DRAIN

CH/DHW MODE PUSH BUTTON

DIRT COLLECCTOR DRAIN

CH TEMPERATURE - ADJ. BUTTON

LCD DISPLAY

SERVICE ACCESS POINT

RESET BUTTON

DHW TEMPE ADJ. BUTTON

DHW TEMPERATURE - ADJ. BUTTON

FLUE OUTLET

MOUNTING BRACKET

18

CH TEMPE ADJ. BUTTON

8

>

>

±0,3 mm

30 120 mm

±0,2 mm

6 30 mm

İmza

E. BİNER

İ. TAŞDEMİR

Aksi belirtilmeyen genel tolerans için ISO 2768-M geçerlidir.

>

>

>

>

±0,8mm

400 1000 mm

±0,5mm

120 400 mm

±0,125 mm

3 6 mm

±0,1 mm

0,5 3 mm

Bu teknik resmin tüm hakları Warhaus'a aittir. Firmanın yazılı izini ve bilgisi olmaksızın üçüncü şahıslarla paylaşılması ve ürettirilmesi yasaktır.

All rights reserved. This drawing is Warmhaus' intellectual property. It's forbidden to reproduce or forward it to any third part without written authorization .

Onay /Drawn aut.

Kontrol /Approved

Çizen /Drawn

Tarih / Date

0.0

Rev.No

Ölçek

A3

10.01.2018

3. Dereceden görünür yüzey

2. Dereceden görünür yüzey

C

B

A

1. Dereceden görünür yüzey

YÜZEY KALİTESİ

Kaplamasız

Kaplamalı

Boyalı

YÜZEY İŞLEMİ

G. EKER

Isıtma ve Soğutma Sistemleri Sanayi Ticaret A.Ş.

Nilüfer / BURSA - TURKEY

(www.warmhaus.com.tr)

Bursa Organize Sanayi Bölgesi Park Cadde No: 10

Teknik resmin orjinal boyutu A3'dür

Ölçü birimi: MM

WARMHAUS BOILER (CH ONLY)

Viwa 50/Viwa 65

70

0

4

158

7

65

207

124

127

207

127

725

30

385

420

40

100

121,5

105,5

90

88,5

136

MODE

RESET

+

-

-

+

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

18

Kalorifer Gidiş

G1 1/4

Kalorifer Dönüş

G1 1/4

GAZ

G 3/4

1

2

9

8

7

6

5

4

3

10

11

12

13

14

15

16

17

230V AC MAIN SUPLLY

MANOMETER

PRESSURE RELIEF VALVE OUTLET

GAS INLET

CENTRAL HEATING FLOW (CH)

CENTRAL HEATING RETURN (CH)

CONDANSATE DRAIN

CH/DHW MODE PUSH BUTTON

DIRT COLLECCTOR DRAIN

CH TEMPERATURE - ADJ. BUTTON

LCD DISPLAY

SERVICE ACCESS POINT

RESET BUTTON

DHW TEMPE ADJ. BUTTON

DHW TEMPERATURE - ADJ. BUTTON

FLUE OUTLET

MOUNTING BRACKET

18

CH TEMPE ADJ. BUTTON

8

>

>

±0,3 mm

30 120 mm

±0,2 mm

6 30 mm

İmza

E. BİNER

İ. TAŞDEMİR

Aksi belirtilmeyen genel tolerans için ISO 2768-M geçerlidir.

>

>

>

>

±0,8mm

400 1000 mm

±0,5mm

120 400 mm

±0,125 mm

3 6 mm

±0,1 mm

0,5 3 mm

Bu teknik resmin tüm hakları Warhaus'a aittir. Firmanın yazılı izini ve bilgisi olmaksızın üçüncü şahıslarla paylaşılması ve ürettirilmesi yasaktır.

All rights reserved. This drawing is Warmhaus' intellectual property. It's forbidden to reproduce or forward it to any third part without written authorization .

Onay /Drawn aut.

Kontrol /Approved

Çizen /Drawn

Tarih / Date

0.0

Rev.No

Ölçek

A3

10.01.2018

3. Dereceden görünür yüzey

2. Dereceden görünür yüzey

C

B

A

1. Dereceden görünür yüzey

YÜZEY KALİTESİ

Kaplamasız

Kaplamalı

Boyalı

YÜZEY İŞLEMİ

G. EKER

Isıtma ve Soğutma Sistemleri Sanayi Ticaret A.Ş.

Nilüfer / BURSA - TURKEY

(www.warmhaus.com.tr)

Bursa Organize Sanayi Bölgesi Park Cadde No: 10

Teknik resmin orjinal boyutu A3'dür

Ölçü birimi: MM

WARMHAUS BOILER (CH ONLY)

Viwa 50/Viwa 65

• It is necessary to leave a spesific

distance 1.0 mt between the

heating device and the building

material containing combustible

material even the maximum

allowable temperature value of 85

° C in the rated heat capacity of

the appliance is not exceeded.

2.1.4. Dimensions and

Connections

7