INSTRUCTIONS

FOR

REMOVAL

OF

FEED

ROLLER

Unplug

machine,

take

o

ff

chip

de

fl

ector,

raise

head,

and

remove

pressure

screws

over

swing

arm.

Remove

two

54

‐

15

pivot

screws

and

remove

swing

arm,

leaving

chain

connected

to

ma ng

sprocket.

Reinstall

each

pivot

screw

with

a

drop

of

medium

strength

thread

locker

.

Take

the

sprocket

o

ff

the

swing

arm

axle

by

pu ng

the

feed

roller

in

a

vise.

Use

a

couple

of

small

adjustable

wrenches

a ached

to

the

fl

at

on

the

long

axle

to

loosen

it.

Put

a

good

square

shank

fl

at

bladed

screwdriver

into

the

slot

on

the

short

axle.

Push

in

as

hard

as

you

can

while

using

a

wrench

on

the

square

shank

of

the

screwdriver

to

loosen

the

short

axle.

Some mes

this

axle

will

not

come

out.

Hack

saw

it

o

ff

if

it

won’t.

If

you

need

to

save

the

roller,

pull

the

roller

out

of

the

swing

arm

by

li ing

it

up

and

pulling

it

out

with

the

short

axle

s ll

in

the

roller.

Reset

the

roller

in

a

vise

and

use

a

small

pipe

wrench

to

remove

it

from

the

roller.

REASSEMBLY The rollers are constructed with a shallow hole in one end and a deeper hole in the

other.

The

P

‐

122

post

side

axle

always

goes

in

the

short

end.

Reinstall

the

P

‐

122

axles

with

two

drops

of

medium

strength

thread

locker

on

the

thread

por on.

Do

not

use

thread

lock

on

P

‐

124

or

P

‐

224.

The

longer

axle

goes

in

the

deeper

end.

See

drawing

for

swing

arm

assembly

with

roller.

POSITION

OF

SPROCKETS

First

posi on

feed

motor

sha

sprockets

with

hubs

facing

in

toward

chain

guard.

The

fi

rst

sprocket

slides

up

to

the

end

of

the

fl

at

on

the

motor

sha

and

the

second

right

up

against

the

fi

rst.

Chains

should

(under

load)

run

in

a

straight

line

from

these

sprockets

to

the

roller

sprockets.

Adjust

the

roller

sprockets

to

achieve

this

alignment.

Feed

roller

sprockets

should

be

posi oned

based

on

the

feed

motor

sprockets

already

posi oned.

The

chains

should

run

in

a

straight

line

from

the

feed

motor

sprockets

to

the

roller

sprockets

when

the

machine

is

under

load.

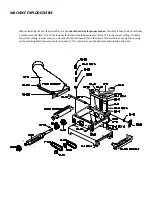

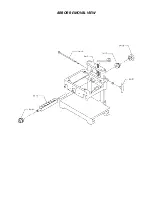

Summary of Contents for 20210492060001

Page 19: ...ARBOR REMOVAL VIEW...

Page 20: ...Stand exploded diagram...

Page 22: ...Notes Maintenance Records...