Wiring your 154/ 206 220Volt Molder

Wire

#

1

is

a

hot

wire

Wire

#

2

is

the

neutral

Wire

#

3

is

a

hot

wire

Cau on:

If

you

have

3

phase

do

not

split

Green/

yellow

stripe

is

ground

the

wild

leg

o

ff

for

1

phase

Wiring

for

your

220V

molder.

Wiring your 154/ 206 3phase molder

Connect

power

to

the

Black,

Red,

and

orange

colored

wires.

Note:

Orange

is

for

a

wild

leg

if

you

have

one.

Failure

to

do

so

will

damage

the

control

panel.

If

you

facility

does

not

have

a

wild

leg

connect

as

per

diagram

If

your

machine

is

rota ng

the

incorrect

way

switch

only

the

black

and

red

wires

green

is

ground

white

is

neutral

Wiring your 209 molder

wire

#

1

is

Hot

wire

#2

is

neutral

wire

#3

is

not

used

Green/

Yellow

stripe

is

ground

Please

note

that

the

Grey

#12

‐

4

wire

that

is

used

on

the

singly

phase

machines

are

preprinted

with

lead

numbers

on

them

below

is

the

wiring

instruc ons

for

wiring

in

your

plug

or

directly

into

your

power

box.

Please

call

with

any

ques ons.

Summary of Contents for 20210492060001

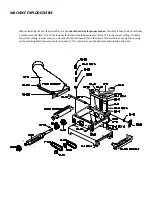

Page 19: ...ARBOR REMOVAL VIEW...

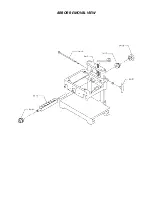

Page 20: ...Stand exploded diagram...

Page 22: ...Notes Maintenance Records...