SAFETY

CHECK

LIST

DON’T

TAKE

UNNECESSARY

RISKS!

Failure to read and apply manual instruc ons will cause poor performance, unnecessary repairs and injury.

Wear

safety

glasses,

hearing

protec on

and

respiratory

protec on.

Disconnect

the

power

before

servicing

or

changing

knives.

Wear

footwear

that

does

not

slip.

This

will

help

you

keep

proper

foo ng

and

balance.

Always

stand

beside

the

machine,

never

in

the

way

of

the

in

‐

feed

and

out

‐

feed

areas.

Keep

knives

sharp

and

clean.

Make

sure

the

machine

has

proper

grounding.

Make

sure

all

guards

are

secured

and

in

working

order.

Remove

all

adjus ng

keys

and

wrenches

before

star ng.

Check

the

stock

for

loose

knots,

nails,

and

foreign

ma er.

Keep

the

machine

in

a

dry,

clean,

and

well

‐

lit

area.

PREPARING TO USE THE MACHINE

1.

Disconnect

the

power

source

while

going

through

these

procedures.

2.

Check

knives

to

ensure

that

the

bolts

are

ght.

If

molding,

set

your

guides

for

the

stock

path

through

the

knife

area.

If

plaining,

you

may

or

may

not

wish

to

set

your

guides.

Many

mes,

they

are

not

needed

in

plaining.

3.

When

molding,

the

head

scale

se ng

must

be

set

to

within

3/16”

of

the

height

of

your

stock

.

The

“0”

on

your

scale

is

set

to

the

top

of

your

GS

‐

2

guide

system

sub

‐

plate.

This

means

you

would

set

the

machine

head

reference

to

the

scale

at

¾”

in

order

to

take

a

full

pro

fi

le

pass

on

a

¾”

piece

of

stock.

You

could

set

the

machine

head

in

reference

to

the

scale

at

15/16”

for

a

maximum

height

fi

rst

pass

(3/4”

+

3/16”).

This

se ng

will

provide

the

proper

roller

tension.

Any

other

se ng

higher

from

the

thickness

of

the

stock

entering

the

machine

is

unacceptable

and

dangerous.

See

the

molding

sec on

for

more

informa on.

4

The

chip

extractor

loads

fi

rst

under

the

out

‐

feed

end

of

the

head

with

a

lip

under

the

cast

head.

You

then

fi

nish

by

a aching

the

chip

extractor

with

its

pin.

Make

sure

the

pin

is

inserted

all

the

way

in

un l

you

feel

it

“catch”

on

the

spring

‐

loaded

catch.

5.

Check

rota onal

clearance

of

the

knife

with

the

chip

extractor

in

place.

Rotate

the

knife

by

hand

at

the

5”

pulley

cut

out

on

the

inner

belt

guard

to

ensure

the

knife

area

is

clear.

6.

Do

not

stand

or

let

others

stand

in

the

out

‐

feed

area

or

directly

in

line

with

the

in

‐

feed

of

the

machine.

7.

With

the

head

set

in

the

proper

posi on,

ghten

the

head

locking

bolt

fi

rmly.

This

is

essen al

for

safety

and

to

ensure

the

machine

head

will

stay

where

you

have

set

it.

8.

Test

a

piece

of

stock,

with

the

machine

o

ff

,

to

see

if

it

will

make

contact

with

the

in

‐

feed

roller.

Summary of Contents for 20210492060001

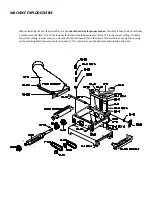

Page 19: ...ARBOR REMOVAL VIEW...

Page 20: ...Stand exploded diagram...

Page 22: ...Notes Maintenance Records...