FEEDING PROBLEMS

Make

sure

that

power

is

disconnected

before

inspec ng

machine.

SYMPTOM

SOLUTION

The

stock

stops

but

the

feed

‐

rollers

con nue

to

turn.

This

is

a

trac on

or

fric on

problem.

Make

sure

your

stock

is

not

binding

in

the

guides.

Make

sure

the

stock

is

of

consistent

width.

Saw

ripping

is

inadequate.

Make

sure

stock

is

the

proper

width

for

the

knife

pro

fi

le.

Make

sure

the

head

is

set

at

the

correct

height.

Check

the

rollers

to

see

if

they

have

a

glossier

than

normal

build

‐

up.

Clean

the

gloss

or

pitch

build

up

o

ff

the

rollers.

Make

sure

adequate

spring

pressure

is

being

ap

‐

plied

to

the

rollers.

Check

the

base

or

bed

for

rust

or

scars.

Replace

worn

rollers.

One

roller

stops

while

the

other

con nues

to

oper

‐

ate.

Check

for

a

loose

set

screw

on

one

of

the

two

chain

sprockets

involved

with

the

roller

that

won’t

operate.

Both

rollers

will

not

turn

Check

for

a

blown

fuse

in

the

Vari

‐

Feed

control.

The

armature

fuse

is

a

2

amp

fuse,

and

the

line

fuse

is

a

5

amp

fuse.

Both

fuses

are

¼”x1

¼”

The

motor

electrical

plug

may

not

be

fully

engaged

in

its

receptacle.

Summary of Contents for 20210492060001

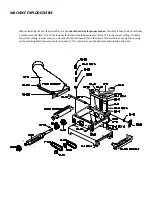

Page 19: ...ARBOR REMOVAL VIEW...

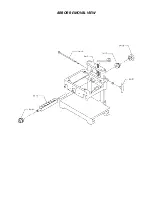

Page 20: ...Stand exploded diagram...

Page 22: ...Notes Maintenance Records...