32

Finish 270 / 250

GB

contents

contents

1

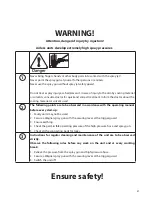

SAFety ReGulAtIOnS FOR AIRleSS SPRAyInG 33

1.1

Flash point _________________________________ 33

1.2

Explosion protection _________________________ 33

1.3

Danger of explosion and fire from sources of

ignition during spraying work _________________ 33

1.4

Danger of injury from the spray jet _____________ 33

1.5

Secure spray gun against unintended operation __ 33

1.6

Recoil of spray gun __________________________ 33

1.7

Breathing equipment as protection against

solvent vapors ______________________________ 33

1.8

Prevention of occupational illnesses ____________ 34

1.9

Max. operating pressure ______________________ 34

1.10 High-pressure hose (safety instructions) _________ 34

1.11 Electrostatic charging

(formation of sparks or flames) ________________ 34

1.12 Use of units on building sites and workshops _____ 34

1.13 Ventilation when spraying in rooms ____________ 34

1.14 Suction installations _________________________ 34

1.15 Earthing of the object ________________________ 34

1.16 Cleaning the unit with solvents ________________ 34

1.17 Cleaning the unit ___________________________ 34

1.18 Work or repairs at the electrical equipment ______ 34

1.19 Work at electrical components _________________ 34

1.20 Setup on an uneven surface ___________________ 35

2

GeneRAl VIeW OF APPlIcAtIOn ____________ 35

2.1

Application ________________________________ 35

2.2

Coating material ____________________________ 35

2.2.1 Coating materials with sharp-edged additional

materials __________________________________ 35

2.2.2 Filtering ___________________________________ 35

3.

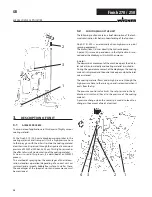

deScRIPtIOn OF unIt _____________________ 36

3.1

Airless process ______________________________ 36

3.2

Functioning of the unit _______________________ 36

3.3

Explanatory diagram _________________________ 37

3.4

Transportation ______________________________ 37

3.5

Trolley backfitting (only Finish 270) _____________ 37

3.6

Technical data Finish 250 _____________________ 38

3.7

Technical data Finish 270 _____________________ 38

4

StARtuP _________________________________ 39

4.1

Unit with suction system _____________________ 39

4.2

unit with upper hopper (5 litres) _______________ 39

4.3

high pressure hose and spray gun ______________ 39

4.4

Connection to the mains network ______________ 39

4.5

Cleaning preserving agent when starting-up of

operation initially ___________________________ 40

4.6

Ventilate unit (hydraulic system) if the sound of

inlet valve is not audible ______________________ 40

4.7

Taking the unit into operation with

coating material ____________________________ 40

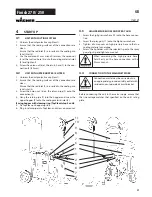

5

SPRAyInG tecHnOlOGy ___________________ 41

6

HAndlInG tHe HIGH-PReSSuRe HOSe _______ 41

6.1

High-pressure hose __________________________ 41

7

InteRRuPtIOn OF WORk ___________________ 41

8

cleAnInG tHe unIt _______________________ 42

8.1

Cleaning the unit from the outside _____________ 43

8.2

Suction filter _______________________________ 43

8.3

High-pressure filter __________________________ 43

8.4

Cleaning the Airless spray gun _________________ 44

9

SeRVIcInG ________________________________ 44

9.1

General servicing ___________________________ 44

9.2

High-pressure hose __________________________ 44

10

RePAIRS At tHe unIt ______________________ 45

10.1 Inlet valve Pusher ___________________________ 45

10.2 Inlet valve _________________________________ 45

10.3 Outlet valve ________________________________ 45

10.4 Pressure control valve ________________________ 46

10.5 Relief valve ________________________________ 46

10.6 Replacing the diaphragm _____________________ 46

10.7 Replacing the power cable ___________________ 47

10.8 Typical wear parts ___________________________ 47

10.9 Connection diagram _________________________ 48

10.10 Remedy in case of faults ______________________ 49

11

SPARe PARtS And AcceSSORIeS ____________ 50

11.1 Finish 270 / 250 accessories ___________________ 50

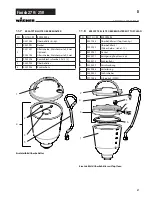

11.2 Spare parts list Pump head ___________________ 51

11.3 Spare parts list Pump-Aggregate ______________ 52

11.4 Spare parts list high-pressure filter _____________ 53

11.5 Spare parts List Trolley _______________________ 54

11.6 Spare parts list suction system (rigid) ___________ 55

11.7 Spare parts list hopper 5l _____________________ 56

11.8 Spare parts list hopper with TopClean ___________ 56

Testing of the unit ________________________________ 57

Important information on product liability_____________ 57

Note on disposal __________________________________ 57

Guarantee declaration _____________________________ 57

CE - declaration__________________________________ 118

European service network _________________________ 120

Summary of Contents for Finish 250

Page 19: ...19 Finish 270 250 10 9 Schaltplan d reparaturen am ger t...

Page 24: ...24 Finish 270 250 ersatzteile und zubeh r Ersatzteilbild Pumpenaggregat d...

Page 48: ...48 Finish 270 250 GB Repairs at the unit 10 9 Connection diagram...

Page 53: ...53 Finish 270 250 GB Spare parts diagram pump aggregate Spare parts and accessories...

Page 77: ...77 Finish 270 250 10 9 Sch ma lectrique F R parations sur l appareil...

Page 107: ...107 Finish 270 250 10 9 Elektrisch schema Reparaties aan het apparaat NL...

Page 112: ...112 Finish 270 250 Onderdelenafbeelding pompaggregaat NL Accessoires en onderdelen...

Page 118: ...118 Finish 270 250 NL CE Verklaring van overeenstemming...

Page 119: ...119 Finish 270 250 NL CE Verklaring van overeenstemming...