VENTING

Certain procedures in this section

require electrical test or

measurements while power is

applied to the machine. Exercise

extreme caution at all times and

follow Arc Flash procedures. If test

points are not easily accessible,

disconnect power and follow

Lockout/Tagout procedures, attach

test equipment and reapply power to

test.

NOTE:

This procedure outlines venting the reservoir

jacket to remove air for proper heat transfer to the

kettle contents.

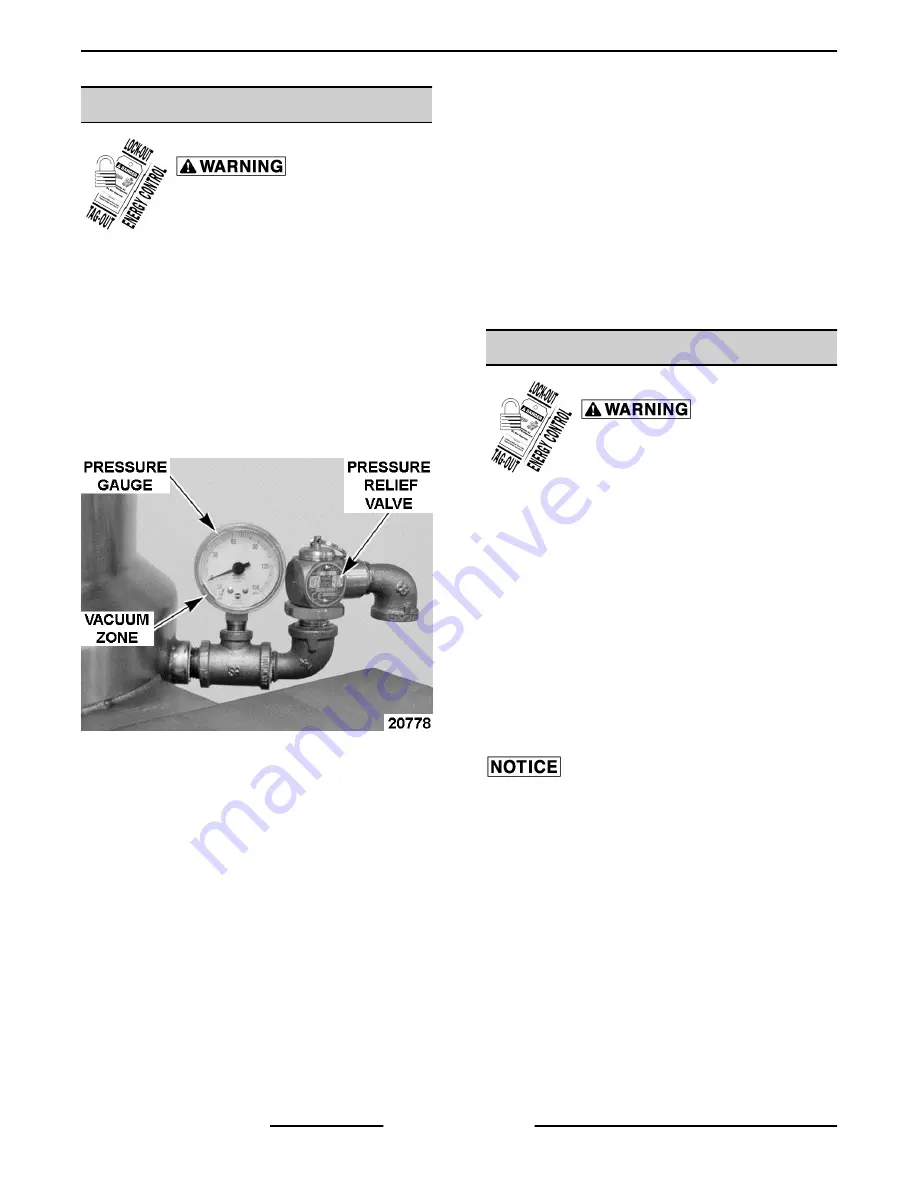

Fig. 33

1.

With the kettle at room temperature, verify

pressure gauge is in the vacuum zone and

reading 25 to 30 in. Hg.

A.

If vacuum is below minimum listed, air must

be removed from reservoir jacket. Continue

with procedure to vent as necessary.

2.

Place kettle in full upright position.

3.

Turn power switch on.

4.

Set temperature dial to highest setting. Allow

kettle to heat until the heat indicator light turns off.

5.

Open pressure relief valve for approximately 10

seconds.

6.

Turn power switch off and allow kettle to cool

(room temperature).

7.

Verify pressure gauge reading is within the

correct vacuum range.

A.

If reading is below minimum listed or will not

maintain proper vacuum, check all threaded

fittings extending from the kettle couplings

(right and rear) for leaks and tightness.

1)

Check pressure relief valve for leaks

from poor valve seating or built up

debris. Manually operate the valve

several times to reseat. Repeat venting

procedure.

2)

If pressure relief valve is

malfunctioning, install a replacement

and check for proper operation.

FILLING THE RESERVOIR JACKET

Certain procedures in this section

require electrical test or

measurements while power is

applied to the machine. Exercise

extreme caution at all times and

follow Arc Flash procedures. If test

points are not easily accessible,

disconnect power and follow

Lockout/Tagout procedures, attach

test equipment and reapply power to

test.

NOTE:

The reservoir water level must be maintained

high enough to submerge the heating element. If low

water light comes on during use, the level may be

below water level probe (LLCO) and must be

replenished before heating can continue. The low

water light will come on when kettle is tilted.

When filling reservoir jacket, use only distilled water.

Partial Refill

1.

Place kettle in full upright position.

2.

Turn power switch on. If low water light is on,

continue with procedure.

3.

Set temperature dial to lowest setting.

4.

Open pressure relief valve until reservoir jacket

is completely vented.

5.

Remove ½" pipe plug from the reservoir jacket fill

elbow at back of kettle.

A.

Insert funnel into the opening and slowly

add water until low water light turns off

(LLCO probe is satisfied).

B.

Turn power switch off.

Electric Countertop Tilting Kettles, K6ETT, K12ETT, K20ETT - SERVICE PROCEDURES AND ADJUSTMENTS

F35496 Rev. A (1117)

Page 18 of 28