Maintenance

90

Electrical system

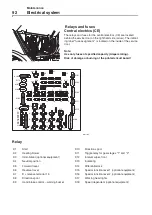

Battery

The battery (1) is located on the right hand side in the engine com-

partment. The battery is maintenance-free and environmentally

friendly. Its double cover with acid separator does not allow any

acid mists to escape to the outside.

Battery disconnecting switch

For longer resting periods of the machine and during repair

work on the electric system the battery disconnecting switch

(2) must be switched off.

Three-phase generator

The engine is fitted with a three-phase generator. The battery

disconnect switch must therefore be switched on when the

engine is running. When switching the battery disconnecting

switch or the starter switch off while the engine is running,

this may cause damage to the generator.

– The connecting poles of the battery must never be mixed up by

mistake. The poles are distinctly marked with (+) or (-). Incor-

rect connection immediately damages the rectifier in the gener-

ator. Before disconnecting battery cables shut down the electric

power by the battery disconnecting switch.

– In case of a fault in the electric system, e.g. a faulty regulator,

compensate the increased water consumption of the battery.

– Unscrew the caps and fill in distilled water up to approx.

10...15 mm / 0.4-0.6' in above the lead plates.

– Turn the plugs back in hand tight.

– Check whether cable lugs and poles are clean, well tightened

and greased with vaseline or similar.

Electric welding

For electric welding the earth terminal must be connected

directly to the part to be welded. Disconnect the battery com-

pletely and pull of or unscrew all plug connections from the

central electric system.

ATTENTION!

Keep sparks and open fire away from the battery!

DANGER OF EXPLOSION

In case of contact with battery acid flush off immediately

with lots of water. In case of caustic injury of the eyes con-

tact a doctor for medical advice.

ATTENTION!

Dispose of old batteries environmentally.

M200091A

1

2

Summary of Contents for L20B

Page 1: ...OPERATOR S MANUAL Ref No VOE21A1000083 English CST Printed in Sweden ...

Page 26: ...Safety 24 Transport ...

Page 40: ...Indicators and control elements 38 Levers and switches ...

Page 48: ...Travel 46 Starting the engine ...

Page 90: ...Maintenance 88 Maintenance every 1500 operating hours ...

Page 110: ...Alphabetic register 108 Ref No VOE21A1000083 English CST Volvo Konz Printed in Sweden ...