Attachments - optional equipment

98

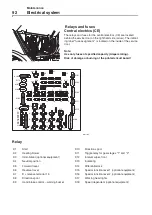

High tipping bucket

High tipping bucket

The high tipping bucket is a combination of carrier and bucket. Dur-

ing tipping the carrier acts like an extension of the lifting frame,

thereby providing a high tipping height. During loading and trans-

port the bucket is tipped back between the carrier and the bucket

body is almost in the same position as a normal bucket, so that

there are almost no disadvantages with respect to ripping power,

lifting force and tipping load.

Operation

Installation of clam bucket, see "Installation and removal of quick

change attachment equipment with auxiliary hydraulics".

The bucket cylinder is activated in the 'tilt function' by means of the

lever (2).

For loading, transporting and lifting tip the bucket back against the

stop on the carrier.

Empty the bucket only when the desired lifting height is reached.

Note:

Avoid tipping of the high tipping bucket with the standard tip-

ping function, or if necessary tip only with low tipping speed,

so that the bucket remains fully tipped back on the carrier.

Avoid tipping and tipping back of the high tipping bucket with full

power against the end stops to prevent bucket and cylinders from

being damaged.

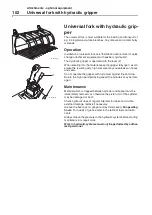

Maintenance

Clean the carrier arms regularly from dirt deposits.

Check hydraulic lines at regular intervals for leaks and visible

external damage, replace if necessary.

Check the rubber buffers on the tipping back stops at regular inter-

vals, replace if necessary.

Lubricate the bucket support and cylinder bearings every

50 oper-

ating hours

. For quality of grease refer to the lubricant table.

Always relieve the pressure in the hydraulic system before starting

maintenance or repair work.

Work in hydraulic systems must only be performed by author-

ized personnel.

M300099A

M200054A

2

1

Summary of Contents for L20B

Page 1: ...OPERATOR S MANUAL Ref No VOE21A1000083 English CST Printed in Sweden ...

Page 26: ...Safety 24 Transport ...

Page 40: ...Indicators and control elements 38 Levers and switches ...

Page 48: ...Travel 46 Starting the engine ...

Page 90: ...Maintenance 88 Maintenance every 1500 operating hours ...

Page 110: ...Alphabetic register 108 Ref No VOE21A1000083 English CST Volvo Konz Printed in Sweden ...