Attachments - optional equipment

102

Universal fork with hydraulic gripper

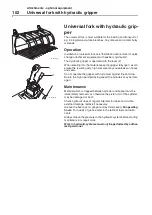

Universal fork with hydraulic grip-

per

The universal fork is most suitable for the loading and transport of

e.g. biological waste, tree branches, hay, manure and similar bulky

materials.

Operation

Installation of universal fork, see "Installation and removal of quick

change attachment equipment with auxiliary hydraulics".

The hydraulic gripper is operated with the lever (2).

When entering into the material keep the gripper fully open, as oth-

erwise the resulting very high pressure may cause leaks on hoses

and seals.

Do not operate the gripper with full power against the end stop.

Due to the high opening/closing speed the cylinders may be dam-

aged.

Maintenance

Material which is trapped between cylinder and bucket must be

immediately removed, as otherwise the piston rod of the cylinder

may be damaged or bent.

Check hydraulic lines at regular intervals for leaks and visible

external damage, replace if necessary.

Grease the bearings on gripper and cylinders every

50 operating

hours

. For quality of grease refer to the table of fuels and lubri-

cants.

Always relieve the pressure in the hydraulic system before starting

maintenance or repair work.

Work in hydraulic systems must only be performed by author-

ized personnel.

M300103A

M200054A

2

1

Summary of Contents for L20B

Page 1: ...OPERATOR S MANUAL Ref No VOE21A1000083 English CST Printed in Sweden ...

Page 26: ...Safety 24 Transport ...

Page 40: ...Indicators and control elements 38 Levers and switches ...

Page 48: ...Travel 46 Starting the engine ...

Page 90: ...Maintenance 88 Maintenance every 1500 operating hours ...

Page 110: ...Alphabetic register 108 Ref No VOE21A1000083 English CST Volvo Konz Printed in Sweden ...