ASH PAN

(2-3 days)

Monitor the ash level every week. Remember that different pellet fuels will have different ash contents.

Ash content is a good indication of fuel efficiency and quality. Refer to “Warnings and Recommendations”

for disposal of ashes.

DO NOT PLACE UNBURNED OR RAW PELLET FUEL IN ASH PAN.

Dump the ashes into a metal container stored away from combustibles. Monitor the ash level every week.

Remember that different pellet fuels will have different ash contents. Ash content is a good indication of

fuel efficiency and quality. Refer to “Warnings and Recommendations” for disposal of ashes.

Vacuum the ash pan and inside the pedestal. CAUTION: BECAUSE THE FLY ASH IS VERY FINE, THE USE

OF A FINE FILTER VACUUM BAG WILL BE REQUIRED TO PREVENT ASH FROM BEING BLOWN BACK

INTO THE ROOM. Please pay special attention that there are no hot ashes in the firebox or there could

be a possibility of a fire hazard inside the vacuum cleaner. Place all hot ashes into a non-combustible

container.

FREESTANDING ASH PAN

:

The VF100 pellet stove freestanding’s ash pan is located under the burner, in the pedestal, and

has a latching mechanism to secure it. To remove the ash pan, unlock the latch on the ash pan

and then pull the pan out.

INSERT ASH PAN:

The VF100 pellet stove insert’s ash pan is located behind the lower grill.

Routine Cleaning and Maintenance

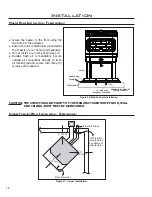

Figure 9: VF100 Heat exchanger

rod.

Heat exchange

tube cleaner rod

HEAT EXCHANGER TUBES

(2-3 days)

The handle for the heat exchanger cleaning rod is pointed out in Figure

9. This handle is to be pulled back and forth a few times

(ONLY WHEN

THE UNIT IS COLD)

in order to clean away any fly ash that may have

collected on the heat exchanger tubes. As different types of pellets

produce different amounts of ash, cleaning of the tubes should be done

on a regular basis to enable the unit to run efficiently.

FRESH AIR INTAKE

(season)

Inspect periodically to be sure that it is not clogged with any foreign

materials.

EXHAUST PASSAGES

(season)

For bi-weekly clean out, ash may be removed from behind the steel

plates by rotating the circular covers located behind the right and left side panels. Loosen the screw on

the disks and open, this will allow vacuuming behind the firebox liner’s plates.

Removal of the firebox backing for bi-annual cleaning:

• Remove the top baffle.

• Lubricate and then remove the seven (7) screws that hold the brick liner in place. Tilt the top of the

brick panel towards the firebox opening and remove from the firebox

• Remove the top rod by first removing the screw that holds it in place, then slide the rod sideways

• Pull the side panels into the center of the firebox, then out

• Pull the center panel out.

• Clean and vacuum all passages thoroughly.

11

Summary of Contents for VF 100A

Page 35: ...35 Parts Diagram Components...

Page 36: ...Parts Diagram Steel 36...