21

7.3

Technical data of Honeywell V 4044F three-way valve

Tab. №. 5

Technical parameters of Honeywell V 4044F motorized zone-type three-way valve

The maximum differential pressure for valve closing (the maximum pressure-

difference between the input and the output, with which the valve can work)

mbar

550

Maximum ambient temperature

°C

50

Heating water temperature

°C

5 - 88

Connecting dimensions (heating water input and output)

Js

inside thread 1

“

Connecting voltage

1/N/PE 230 V AC 50 Hz TN-S

Electric cover

IP 40

Environment

according to ČSN 33 2000 - 7 – 701 ed. 2,

the boiler mustn't be installed in 0,1,2 zones

Remark: a 5-core connecting cable is delivered together with the valve

1

2

3

4

5

Pressure loss [m of water column]

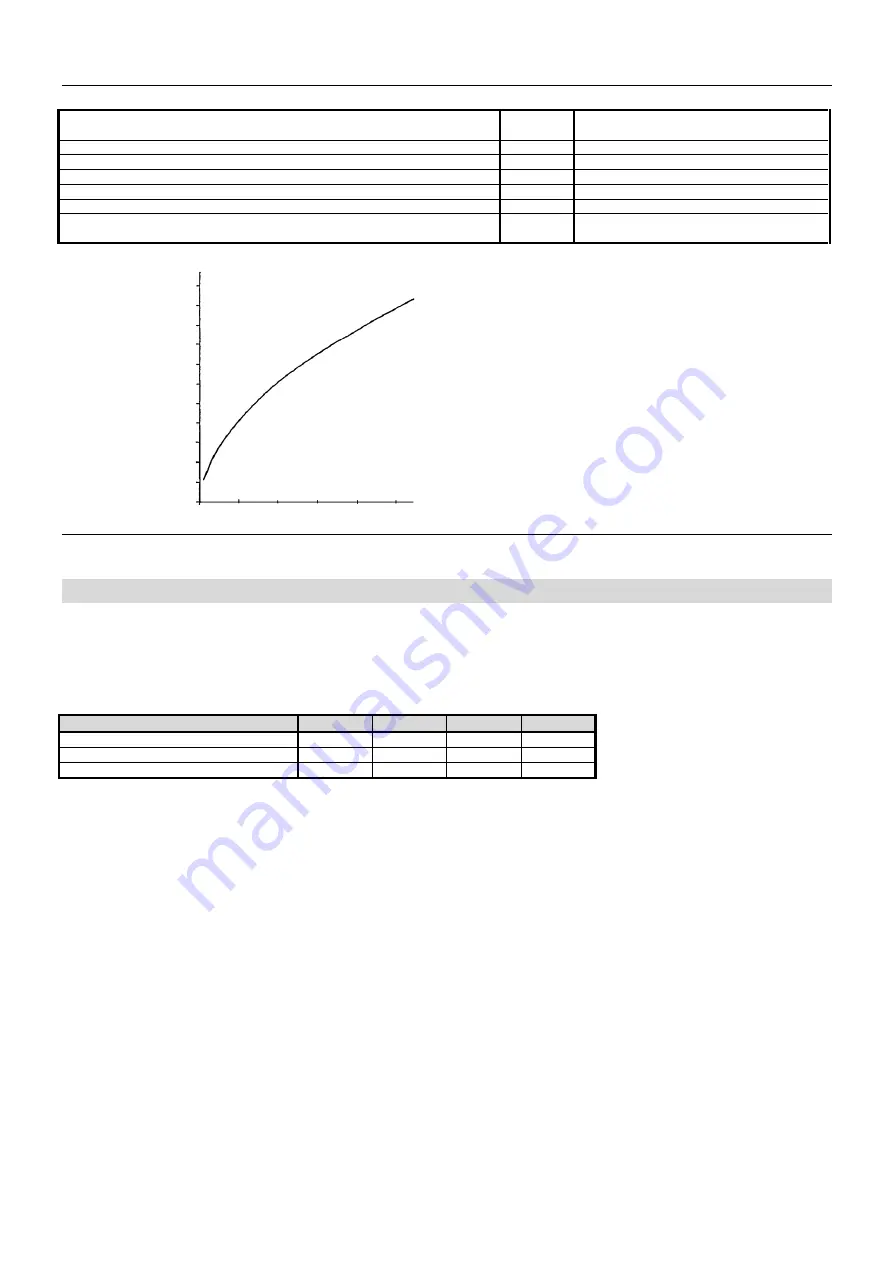

Fig. №. 18

Honeywell V 4044F three-way valve characteristics

8

Forced flue gases exhaust

The boiler can be equipped with a flue exhauster (only OSV hereinafter) which enables installation of the boiler also in the space where it

cannot be connected to a chimney and flue gases can be led away into the outdoor space through the wall

– according to TPG G 800 01 „Flue

outfall from the gas fuel appliances on the exterior wall (facade)".

This complementary device can be used in the whole output range of boilers designated for natural gas combustion. Two-sectional boilers can

only be operated with rated output.

Tab. №. 6

OSV types assignment to VIADRUS GARDE G 42 ECO boiler

number of sections

2

3

4

5

boiler power (kW)

8

12-17

18-26

22-30

OSV type

OSV 1-2

OSV 1-3

OSV 1-4

OSV 2-5

Neck diameter D (mm)

80

110

130

160

The operation safety is ensured by a differential pressure switch which switches on the burner only on condition of a proper exhaustion. Other

safety element watching the flue gases escape into the boiler room is the flue gases reverse flow safety device which belongs to boilers

standard equipment.

The flue gases venting can be carried out in two ways according to the figures No. 19 and 20:

We recommend using the version according to fig.. 19 provided the boiler is designed so that it complies with observation of the maximum

height of H = 1,5 m and calculations according to table No. 7. The pressure loss is minimum in this design.

Fig. 20 shows an example of a set in a combined design with separate parts; the calculation according to the table No. 7 has to be observed

here, i.e. it means the max. value of flow resistance coefficient must not be exceeded.

The flue-gases exhausting ventilator (OSV) is being put on the boiler draught diverter neck or on the smoke-flue vertical tube inserted in the

neck of the draught diverter. The neck extension must be direct and vertical, its diameter must be the same as the diameter of the neck and it

must not be longer than

H - 1,5 m

.

OSV can rotate round the vertical axis by 90° to the left or to the right depending on the needed direction of flue gases outfall.

Wiring is done through the interconnection with boiler terminal board. Individual conductors are signed by numbers that correspond to numbers

on boiler terminal board:

Terminal no. 8

– blue conductor

Terminal no. 9

– black conductor

Terminal no. 10

– brawn conductor

Terminal PE

– yellow &.green conductor

The jumper between terminals no. 9 and 10 must be removed in the boiler terminal board. Fix the conductor, which is led from the ventilator, in

the point of its entering, to the cladding and the panel with a MEOS clip to protect is against its rapture.

Following principles must be observed when assembling the flue gas ducting:

-

every joint of flue gas ducting must be secured by at least one sheet-metal screw in order to prevent it from disjunction;

-

the length of particular parts insertion is 50 mm;

-

the neck of the ventilator and the draught diverter must be secured by at least two sheet-metal screws in a the opposite position toward

each other at the point of joint;

-

the flue gases exhaust must be led just vertically or horizontally but never downwards (there is only allowed the max. gradie

nt 3°

downwards for condensate outlet; however, due to the high electric power of the ventilator, no condensate should be created);

100

80

60

40

20

Dependence of pressure loss on

flow rate

Flow rate

[l/min]