7.3

HYDRAULIC FITTING TORQUE

TIGHTENING FLARE TYPE TUBE FITTING*

1. Check flare and flare seat for defects that

might cause leakage.

2. Align tube with fitting before tightening.

3. Lubricate connection and hand tighten

swivel nut until snug.

4. To prevent twisting the tube(s), use two

wrenches. Place one wrench on the

connector body and with the second

tighten the swivel nut to the torque shown.

*

The torque values shown are based on

lubricated connections as in reassembly.

Recommended

Nut Size

Turns to Tighten

Tube

Across

(After Finger

Size

Flats

Torque Value* Tightening)

OD

(in.)

(in.)

(N.m) (lb-ft)

(Flats) (Turns)

3/16

7/16

8

6

1

1/6

1/4

9/16

12

9

1

1/6

5/16

5/8

16

12

1

1/6

3/8

11/16

24

18

1

1/6

1/2

7/8

46

34

1

1/6

5/8

1

62

46

1

1/6

3/4

1-1/4

102

75

3/4

1/8

7/8

1-3/8

122

90

3/4

1/8

SPECIFICATIONS

47

Summary of Contents for H Series

Page 1: ...ROUND BALE GRINDER MODEL H OPERATOR S MANUAL AND PARTS BOOK INC FARM EQUIPMENT MANUFACTURER...

Page 6: ...2...

Page 31: ...Fig 23 MANGER FEEDING OPERATION 27...

Page 34: ...OPERATION 30...

Page 46: ...SERVICE MAINTENANCE 42...

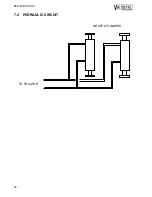

Page 52: ...7 4 HYDRAULIC CIRCUIT SPECIFICATIONS 48 GRATE CYLINDERS TO TRACTOR...

Page 53: ......

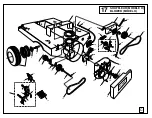

Page 66: ...H C R PPE PPER CH 16 8 7 10 9 11 4 15 14 1 13 12 2 6 5 3 17 CUVE TUB D 9 10 17 18 19...

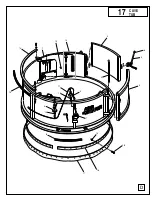

Page 69: ...1 5 9 2 3 4 6 8 17 CHUTE MANUELLE MANUAL CHUTE E 7 7 6 2...

Page 75: ...1 3 5 2 4 17 CHUTE MANUELLE D FLECTEUR MANUAL CHUTE DEFLECTOR H 6 6 4 2 8 10 12 9 7 9 11...

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......