INSTALLATION AND WIRING 2-1

2.0 INSTALLATION AND WIRING

Section 2.0 provides the information needed to

properly mount and wire the PHOENIX Drive. Since

most start-up difficulties are the result of incorrect

wiring, it is essential that the wiring is done as

instructed. Read and understand this section in its

entirety before actual installation begins.

2.1 SAFETY WARNINGS

WARNING

Only qualified electrical personnel familiar with the

construction and operation of this equipment and the

hazards involved should install, adjust, operate or

service this equipment.

WARNING

The control and its associated motors and operator

control devices must be installed and grounded in

accordance with all national and local codes (NEC,

VDE 0160, BSI, etc.). To reduce the potential for

electric shock, disconnect all power sources before

initiating any maintenance or repairs. Keep fingers

and foreign objects away from ventilation and other

openings. Keep air passages clear. Potentially lethal

voltages exist within the drive enclosure and

connections. Use extreme caution during installation

and start-up.

WARNING

The following information is only a guide for proper

installation. US Drives cannot assume responsibility

for the compliance or noncompliance to any code,

national, local or otherwise for the proper installation

of this drive or associated equipment. A hazard of

personal injury and/or equipment damage exists if

codes are ignored during the installation.

2.2 INITIAL CHECKS

Before installing the PHOENIX Drive, check the unit for

physical damage sustained during shipment. If

damaged, file a claim with the shipper and return for

repair following the procedures outlined on the back

cover. If no damage is observed, remove all shipping

restraints and padding. Check drive nameplate data

for conformance with the AC power source and motor.

2.3 DETERMINING CONTROL LOCATION

The PHOENIX Drive is suitable for most well-ventilated

factory areas where industrial equipment is installed.

Locations subject to steam vapors or excessive

moisture, oil vapors, flammable or combustible vapors,

chemical fumes, corrosive gases or liquids, or excessive

dirt, dust or lint should be avoided unless an

appropriate enclosure has been supplied or a source of

clean air is supplied to the enclosure. The location

should be dry and the ambient temperature should not

exceed 122

°

F (50

°

C). If the mounting location is

subject to vibration, the unit should be shock mounted.

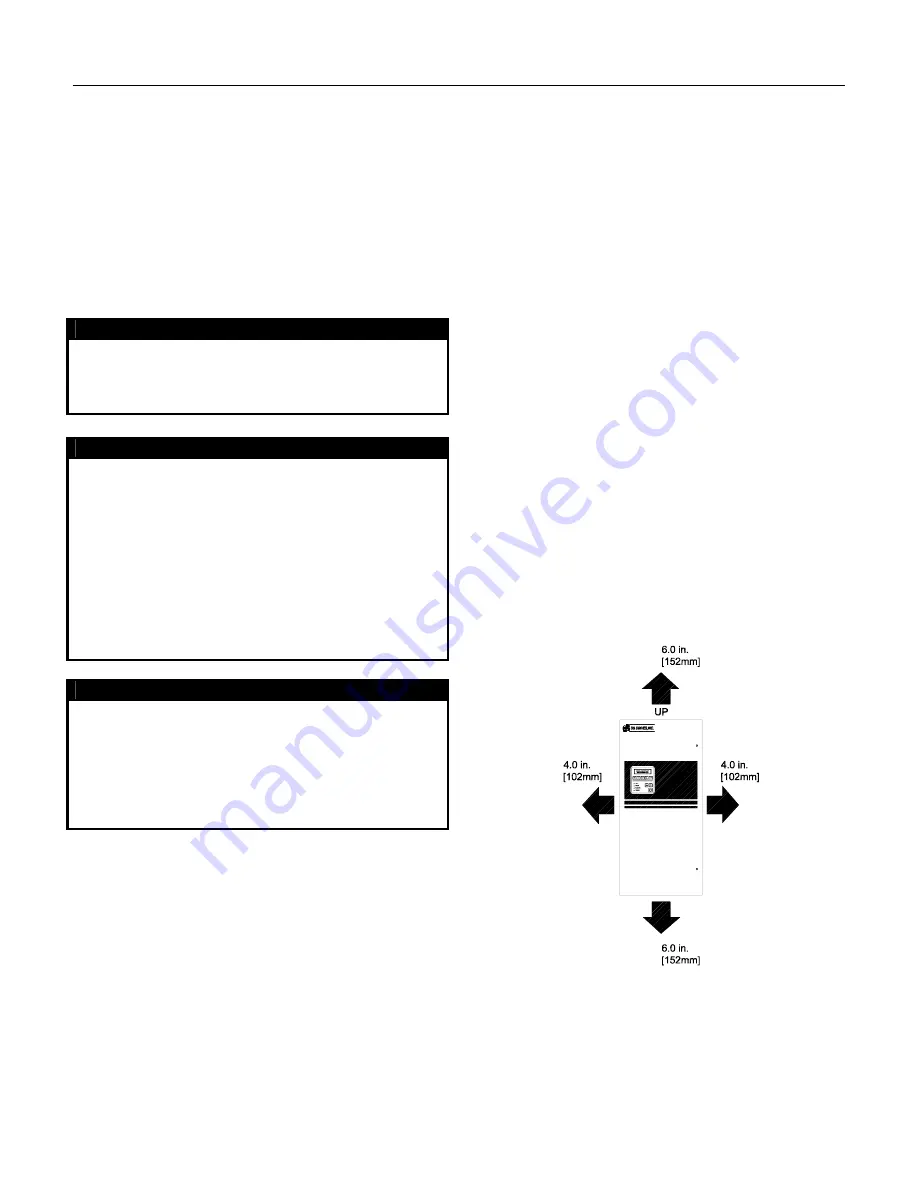

2.4 MOUNTING

Figure 2-1 shows the minimum required surrounding

air space for panel mounted PHOENIX Drives (size 0

through size 3 units). Note that the panel mounted

units must be mounted in an upright position. Figure

2-2a shows dimensional information for size 1 through

size 2 units. Figure 2-2 shows dimensional information

for size 0. Figure 2-2b shows dimensional information

for size 3. If through panel mounting is chosen

(available on size 0 through size 3 Drives), a suitable

sealant should be applied to the mounting faces of the

drive and the panel to prevent leakage.

Figure 2-1

Minimum Required Surrounding Air

Space for size 0 through size 3

PHOENIX Drives

Summary of Contents for PHOENIX EX

Page 1: ...INSTRUCTION MANUAL PHOENIX EX 3 TO 3500 HP VECTOR AC DRIVE ...

Page 12: ...1 8 INTRODUCTION END INTRODUCTION SECTION ...

Page 28: ...2 16 INSTALLATION AND WIRING Figure 2 3 Recommended Power Wiring ...

Page 32: ...2 20 INSTALLATION AND WIRING Figure 2 5 Control Logic and Signal Wiring ...

Page 56: ...Figure 4 2 Menu 1 Frequency Reference Limits and Filters 4 2 MENU AND PARAMETER DESCRIPTION ...

Page 57: ...Figure 4 3 Menu 2 Ramps MENU AND PARAMETER DESCRIPTION 4 3 ...

Page 58: ...Figure 4 4 Menu 3 Speed Input and Speed Loop 4 4 MENU AND PARAMETER DESCRIPTION ...

Page 59: ...MENU AND PARAMETER DESCRIPTION 4 5 Figure 4 5 Menu 4 Current Limits Torque Flux Control ...

Page 60: ...4 6 MENU AND PARAMETER DESCRIPTION Figure 4 6 Menu 5 Motor Control ...

Page 61: ...MENU AND PARAMETER DESCRIPTION 4 7 Figure 4 7 Menu 6 Operational Modes ...

Page 62: ...Figure 4 8 Menu 7 Analog Inputs and Outputs 4 8 MENU AND PARAMETER DESCRIPTION ...

Page 66: ...4 12 MENU AND PARAMETER DESCRIPTION Figure 4 12 Menu 11 Miscellaneous ...

Page 68: ...4 14 MENU AND PARAMETER DESCRIPTION Figure 4 14 Menu 12 Open Loop Brake Function 2 of 5 ...

Page 69: ...MENU AND PARAMETER DESCRIPTION 4 15 Figure 4 15 Menu 12 Closed Loop Brake Function 3 of 5 ...

Page 70: ...4 16 MENU AND PARAMETER DESCRIPTION Figure 4 16 Menu 12 Closed Loop Brake Function 4 of 5 ...

Page 71: ...MENU AND PARAMETER DESCRIPTION 4 17 Figure 4 17 Menu 12 Closed Loop Brake Function 5 of 5 ...

Page 73: ...Figure 4 19 Menu 14 PID Control Loop MENU AND PARAMETER DESCRIPTION 4 19 ...

Page 74: ...Figure 4 20 Menu 15 Position Control 1 of 2 4 20 MENU AND PARAMETER DESCRIPTION ...

Page 75: ...MENU AND PARAMETER DESCRIPTION 4 21 Figure 4 21 Menu 15 Position Control 2 of 2 ...

Page 76: ...Figure 4 22 Menu 17 2nd Motor Parameters 4 22 MENU AND PARAMETER DESCRIPTION ...

Page 153: ...APPENDIX A 3 Standard Drive with Manual Bypass Setup Diagram 2 of 2 ...

Page 155: ...APPENDIX A 5 Interconnect for Option Boards 3000 4040 120 3000 4050 120 ...

Page 156: ...APPENDIX A 6 Isolated Communication Card P N 3000 4135 with Jumper on Position 1 1 of 3 ...

Page 157: ...APPENDIX A 7 Isolated Communication Card P N 3000 4135 with Jumper on Position 2 2 of 3 ...

Page 158: ...APPENDIX A 8 Isolated Communication Card P N 3000 4135 3 of 3 Mounting Diagram ...

Page 162: ...APPENDIX A 12 Digital Encoder Card P N 3000 4140 1 3 of 3 Mounting Diagram ...

Page 164: ...APPENDIX A 14 I O Expansion Board 3000 4150 2 of 2 Mounting Diagram ...

Page 167: ...APPENDIX A 17 Digital Encoder 2 3000 4160 Page 3 of 3 Mounting Diagram ...

Page 168: ...APPENDIX A 18 THIS PAGE INTENTIONALLY LEFT BLANK ...