17

NOTICE TO MASSACHUSETTS APPLIANCE DEALERS:

Be sure this document is included in all gas range appliances sold to consumers in

the State of Massachusetts.

NOTICE: Massachusetts law requires the following:

• Appliances must be installed by a licensed plumber or gas fitter.

• Appliances must be connected with a three (3) foot (36” maximum length) flexible

gas connector and

• A “T” handle type manual gas valve in the gas supply line to the appliance.

Have the dealer where you purchase your new range install it or have him rec-

ommend a qualified installer. Installation must conform with local codes. In the

absence of local codes, the installation must conform with the National Fuel Gas

Code, ANSI Z223.1-Latest Edition in the U.S.A. or the CAN/CGA B149.1 or .2 In-

stallation Codes in Canada.

The range should be connected to the supply line with 1/2-inch black iron pipe or

a certified flexible type range connector. To prevent gas leaks, put an approved

sealing compound, which is resistant to liquefied petroleum gases, on all threaded

connections.

Important:

Do not apply pressure directly to the range manifold pipe when tighten-

ing supply connections. The manifold pipe should be held securely at the pressure

regulator to prevent twisting. Hold the pressure regulator with a wrench during the

tightening of the connection, or the manifold pipe may be twisted and split, and

cause a dangerous leak.

The installation of ranges designed for manufactured (mobile) home installation

must conform with the Manufactured Construction and Safety, Title 24 CFR, Part

3280, [formerly the Federal standard for Mobile Home Construction and Safety,

Title 24, HUD (Part 280)] in the U.S.A. or C.S.A. Standard CAN/CGA Z240.4.2 in

Canada or, when such standards are not applicable with local codes.

The installation of ranges designed for recreational vehicle installation must con-

form to state or other codes and in the absence of such codes with the standard

for recreational vehicles ANSI A119.2.2–1982 in the U.S.A. or CAN/CGA Z240.4.2

in Canada. The installation of appliances designed for recreational park trailers

must conform to recreational park trailers, ANSI A119.5.

Note:

Check all piping connections in the unit for leaks. Never use an open flame

to check for gas leaks. Use a soap solution with a recommended ratio of 75%

water and 25% dish washing soap. It’s possible for connections made at the fac-

tory to leak, due to vibration encountered in transportation. Make certain you have

checked them all,

and repair any connections that leak.

GAS CONNECTIONS (All Units)

Summary of Contents for Prestige UGP-24V PC1 B

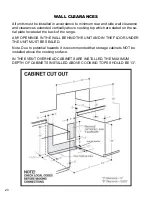

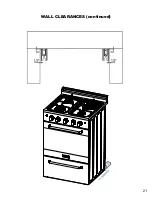

Page 21: ...21 WALL CLEARANCES continued ...

Page 46: ...UGP 24V PC1 S S WIRING DIAGRAM 46 ...

Page 48: ...48 UGP 24V PC1 S S PARTS DIAGRAM AND LIST ...

Page 53: ...NOTES 53 ...