Summary of Contents for RG1025

Page 2: ......

Page 18: ...C I B UNIGAS M039144CD 18 BERGONZO NOZZLES Fig 15 ...

Page 19: ...C I B UNIGAS M039144CD 19 Fig 16 ...

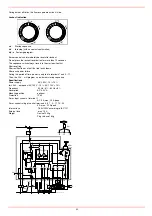

Page 20: ...C I B UNIGAS M039144CD 20 Fig 17 ...

Page 21: ...C I B UNIGAS M039144CD 21 Fig 18 ...

Page 38: ......

Page 39: ......