2-10

Service

TIRE PRESSURE

The following is to be used as a

general guide

for tire infl ation and fi gures can vary depending

on specifi c brand of tire used.

It is important

that

tires are inspected after unit is loaded.

Start with minimum pressure indicated. The tire

should stand up with no side-wall buckling or dis-

tress as tire rolls. Record the pressure needed

to support the full load and maintain this pres-

sure to achieve proper tire life.

Do not exceed

maximum recommended tire pressure.

Recommended......100 PSI maximum.

TIRE WARRANTY

For questions regarding new tire warranty,

please contact your local original equipment tire

dealer. Used tires carry no warranty. Follow-

ing are phone numbers and Websites for your

convenience:

Firestone

www.fi restoneag.com

Phone

800-847-3364

Titan

www.titan-intl.com

or

Phone

800-USA-BEAR

Goodyear

Fax 515-265-9301

Trelleborg

www.trelleborg.com

Phone

866-633-8473

Greenball

www.greenball.com

Phone nearest location:

California

800-937-5204

Georgia

800-283-4569

Florida

800-935-0200

Indiana

800-426-4068

Pennsylvania

800-869-6787

Tennessee

800-946-9412

Ohio

800-840-7295

(All tire pressures in psi)

WHEEL TORQUE REQUIREMENTS

CAUTION! IMPROPERLY TORQUED

WHEEL NUTS/BOLTS CAN CAUSE A

LOSS OF IMPLEMENT CONTROL AND MA-

CHINE DAMAGE. TORQUE WHEEL NUTS/

BOLTS TO VALUES IN TABLE. CHECK

TORQUE BEFORE INITIAL USE, AFTER ONE

HOUR OF UNLOADED USE OR AFTER FIRST

LOAD, AND EACH LOAD UNTIL WHEEL NUTS/

BOLTS MAINTAIN TORQUE VALUE. CHECK

TORQUE EVERY 10 HOURS OF USE THERE-

AFTER. AFTER EACH WHEEL REMOVAL

START TORQUE PROCESS FROM BEGINNING.

WARRANTY DOES NOT COVER FAILURES

CAUSED BY IMPROPERLY TORQUED WHEEL

NUTS/BOLTS.

Failure to check torque before fi rst load may

damage wheel nut/bolt seats. Once seats are

damaged, it will become impossible to keep nuts/

bolts tight. Tighten nuts/bolts to the applicable

torque value shown below. Start all nuts/bolts by

hand to prevent cross threading. Torque nuts/

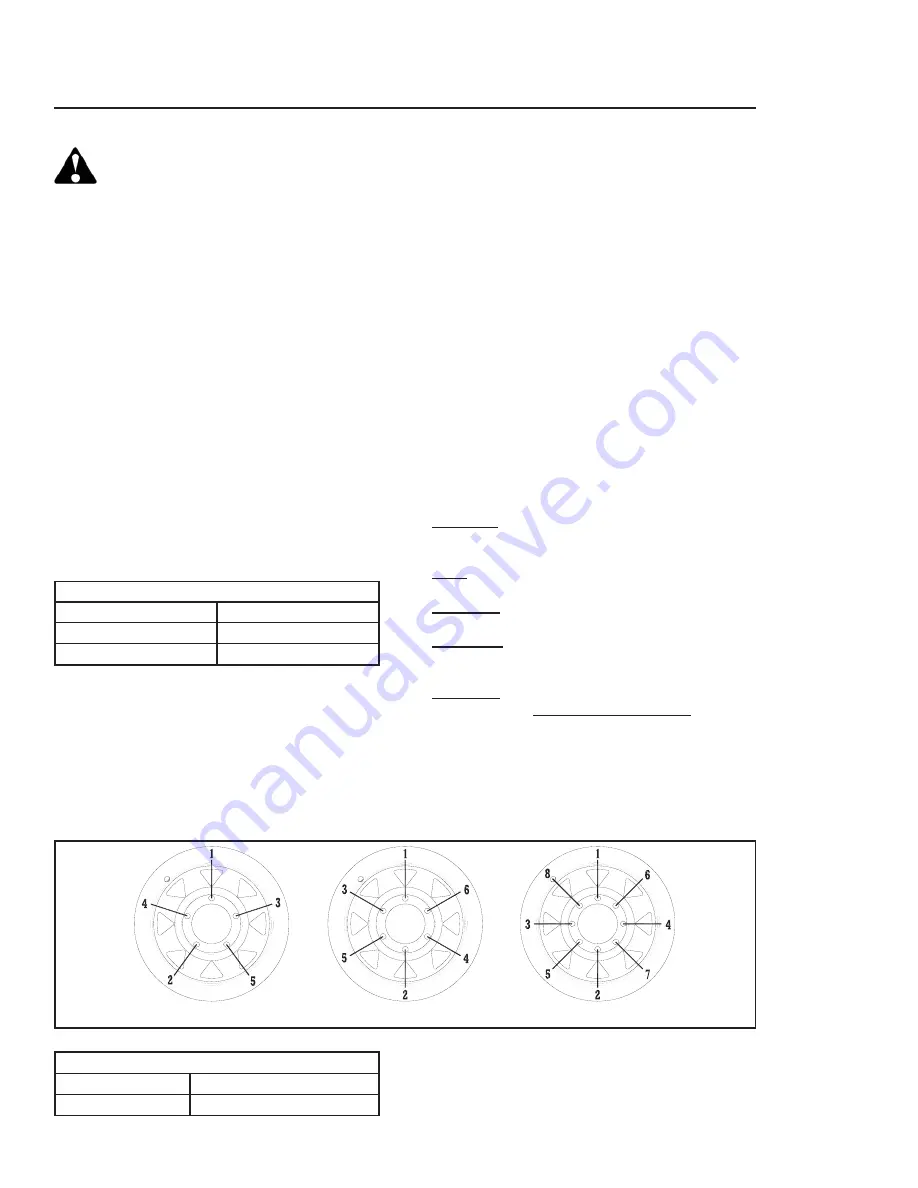

bolts in the recommended sequence as shown

in Diagram 1.

DIAGRAM 1

WHEEL HARDWARE

SIZE

FOOT-POUNDS

1/2-20 (UNF)

75 FT.-LBS.

9/16-18 (UNF)

110 FT.-LBS.

WHEEL TORQUE CHART & TIRE SPECIFICATIONS

Nut/Bolt Location:

1/2-20 (UNF)

Single Wheels

9/16-18 (UNF)

Single Wheels

5 BOLT

6 BOLT

8 BOLT

Summary of Contents for Unverferth 2750

Page 12: ...12 NOTES March 2013...

Page 28: ...Operation 1 16 NOTES...

Page 42: ...2 14 Service MASTER DISCONNECT SWITCH ELECTRICAL SCHEMATIC...

Page 44: ...2 16 Service TRAILER LIGHTING BRAKE ELECTRICAL SCHEMATIC...

Page 45: ...2 17 Service SEED TANK LIGHTING ELECTRICAL SCHEMATIC...

Page 46: ...2 18 Service NOTES...

Page 64: ...3 18 Assembly NOTES...

Page 65: ...4 1 Parts SECTION IV PARTS...

Page 66: ...4 2 Parts OM04430 BOX DECALS 14 14 15...

Page 68: ...4 4 Parts LADDER COMPONENTS OM 04435...

Page 70: ...4 6 Parts DOOR WINDOW PIVOT COMPONENTS OM04431 Revised 082310 1 February 2013...

Page 74: ...4 10 Parts HOPPER COMPONENTS FOR 6 TUBE CONVEYOR OM04428 February 2013...

Page 78: ...4 14 Parts IDLER END COMPONENTS FOR 6 TUBE CONVEYOR OM04427 26 February 2013...

Page 80: ...4 16 Parts IDLER END COMPONENTS FOR 8 TUBE CONVEYOR February 2013...

Page 82: ...4 18 Parts DISCHARGE SPOUT COMPONENTS FOR 6 TUBE CONVEYOR OM04426 Revised 082310 1...

Page 84: ...4 20 Parts DISCHARGE SPOUT COMPONENTS FOR 8 TUBE CONVEYOR OM04539B...

Page 94: ...4 30 Parts CABLE RETURN TARP SYSTEM COMPONENTS February 2013...

Page 100: ...4 36 Parts AXLE WHEEL COMPONENTS Revised 082310 1...

Page 102: ...4 38 Parts UNDERCARRIAGE ELECTRICAL COMPONENTS 24896 WIRING HARNESS...

Page 108: ...4 44 Parts OPTIONAL GOOSE NECK HITCH COMPONENTS Front View Rear View February 2013...

Page 111: ...4 47 Parts NOTES February 2013...

Page 112: ...L MANUALS SEEDTENDER 27260 INDD MARCH 2013 3 JUNE 2014 4 MARCH 2015 4 www unverferth com...