-16-

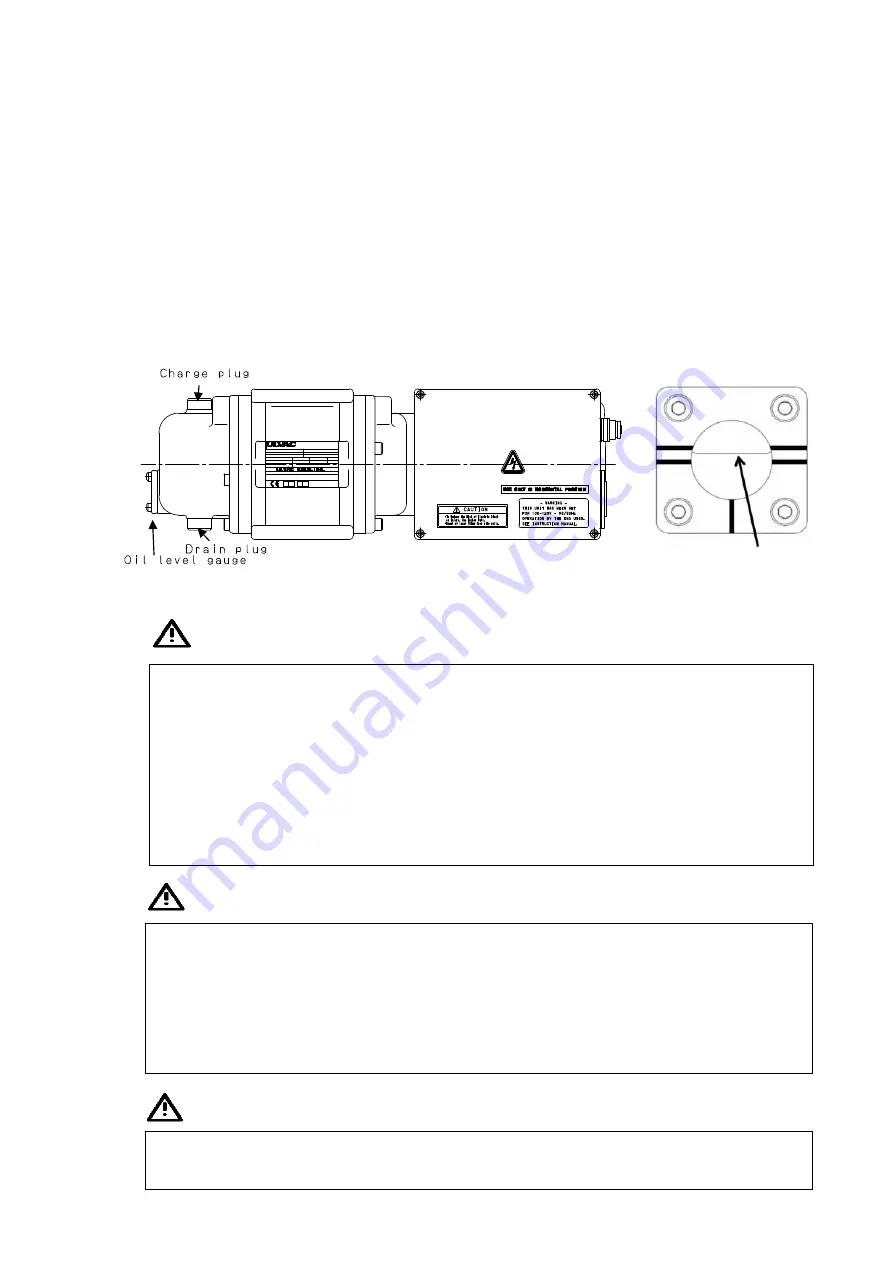

4.6 Oil charge

Remove an oil charge plug to show in Fig.11, and supply with lubricating oil.

Lubricating oil uses vacuum-pump oil SMR-200.

Refuel it confirm oil quantity with an oil level gauge of Fig.12, and to become

between two lines.

When corrosive gas is exhausted at MBS - 053 - 01, it is also possible to use

fluorine oil (

FOMBLIN YLVAC06/6).

Caution

Lubricating oil side must not protrude two red lines.

Oil flows into pump chamber through a clearance seal when supply too much

with lubricating oil.

When oil is in pump chamber, an ultimate pressure rises, and there is a case to

give a fore pump a failure.

In addition, you cause a sound level increase, the pump breakage when the

pump runs with lack of lubricating oil.

①

Wear protective equipment such as rubber gloves and safety goggles.

②

Be sure to read the attached “Material Data Sheet” before adding oil. If the oil

accidentally comes into contact with your hands or enters your eyes, take proper

measures in accordance with the section “First-aid treatment” shown in “Material

Safety Data Sheet.”

Use only oils specified by us. If other oils are used, the pump performance will

deteriorate or its life will shorten.

Fig.11 Oil plug, oil level gauge position

Fig.12 Oil level gauge

Note

Caution

Oil face