-22-

6. Maintenance

6.1 Daily inspection

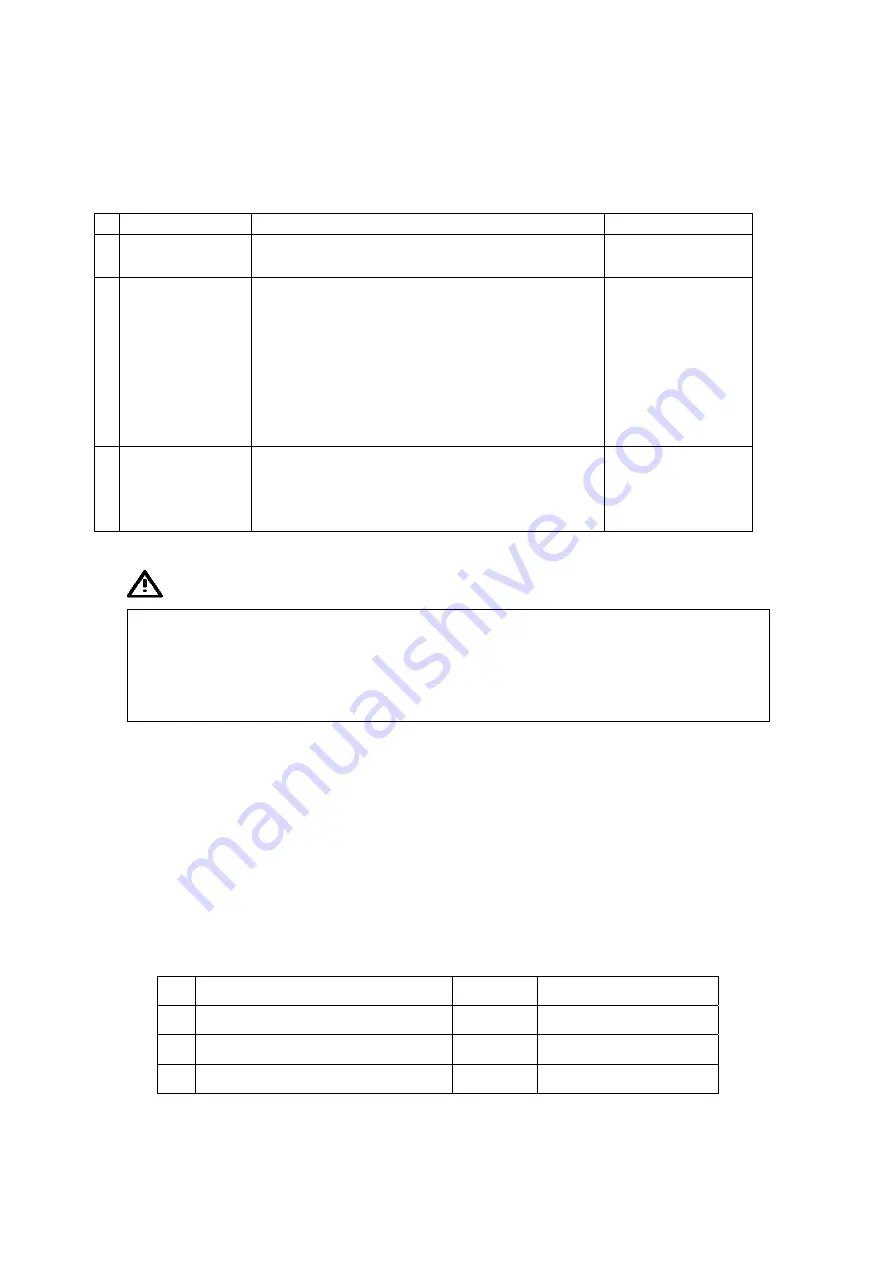

Please execute inspection of table 5.

Table 5 Daily inspections

Check item

Check contents

Check interval

1 0il

level

Is there an oil level between two lines of

level gauge?

Once a week

2

Color change

of oil

Cloudiness of oil:

Because the moisture of exhaust-gases

gets mixed in oil, and ultimate pressure

rises, change it in brand new oil.

Oil becomes black

:

It is feared that a bearing, timing gear are

worn. Please take inspection in our

company service division.

Once a week

3

Oil plug,

Drain plug

Check whether plugs does not loosen.

When a plug loosens, rise of an ultimate

pressure and oil leaking out come.

Once a week

①

Pulled out the power plug before starting inspection and do not turn it on while

inspection is in progress. Doing so will result in injury.

②

The pump is very hot immediately after it is stopped. Wait for 10 minutes until the pump

has cooled down completely and then start inspection. There is a risk of burns.

6.2 Long interval maintenance

Can use it for a long term by executing maintenance by table 6.

This maintenance needs a professional skill.

Please order it from our company service division.

Table 6 Change parts of long-term maintenance

Change parts name

Quantity

Maintenance interval

1

Motor side bearing

2

30,000 hours

2

Gear side bearing

2

60,000 hours

3 Motor

1

40,000

hours

Caution