32

ULVAC CRYOGENICS INCORPORATED

13. Troubleshooting

When any failure or unusual phenomenon occurs in the equipment, at first perform

the fault diagnosis shown in the following table. When contacting us, it is

requested to check the lighting status of PLC lamp arranged to the electrical circuit

in advance.

Problem

Possible Cause

Corrective Action

(1) Equipment fails to

start by pressing the

RUN/STOP switch.

(The RUN/STOP

switch does not light)

The main power source

(breaker) is turned OFF.

Turn ON the main power

source.

The power cord is not

connected.

Connect the power cord

correctly.

The circuit breaker is turned

OFF.

Turn ON the circuit breaker.

The fuse is blown.

Replace fuse with new one.

If the fuse is blown

repeatedly, please contact

us.

The emergency stop button is

pressed.

Reset the emergency stop

switch by turning it to the

right, and restart.

(2) Equipment fails to

start even if the

RUN/STOP switch

lights up.

LN

2

level is not decreased to

the re-starting level.

When LN

2

level is decreased

to 75% or less, the

production starts

automatically.

(3) Power breaker trips.

Short-circuit or electric

leakages occur.

Please contact us.

(4) GN2 AL. lights on.

The RUN/STOP lamp

flickers at the same

time.

GN10i is suspended.

Check the electric wiring of

GN-10i, or

Suspend and resume EMP

and GN-10i.

IM-120 is suspended.

Check the dry air supply

pressure.

Nitrogen gas supply

decreases, or the pressure is

lowered temporarily.

Refer to “9-5-3. Corrective

action when GN2 AL. occurs”

and restart EMP 14A.

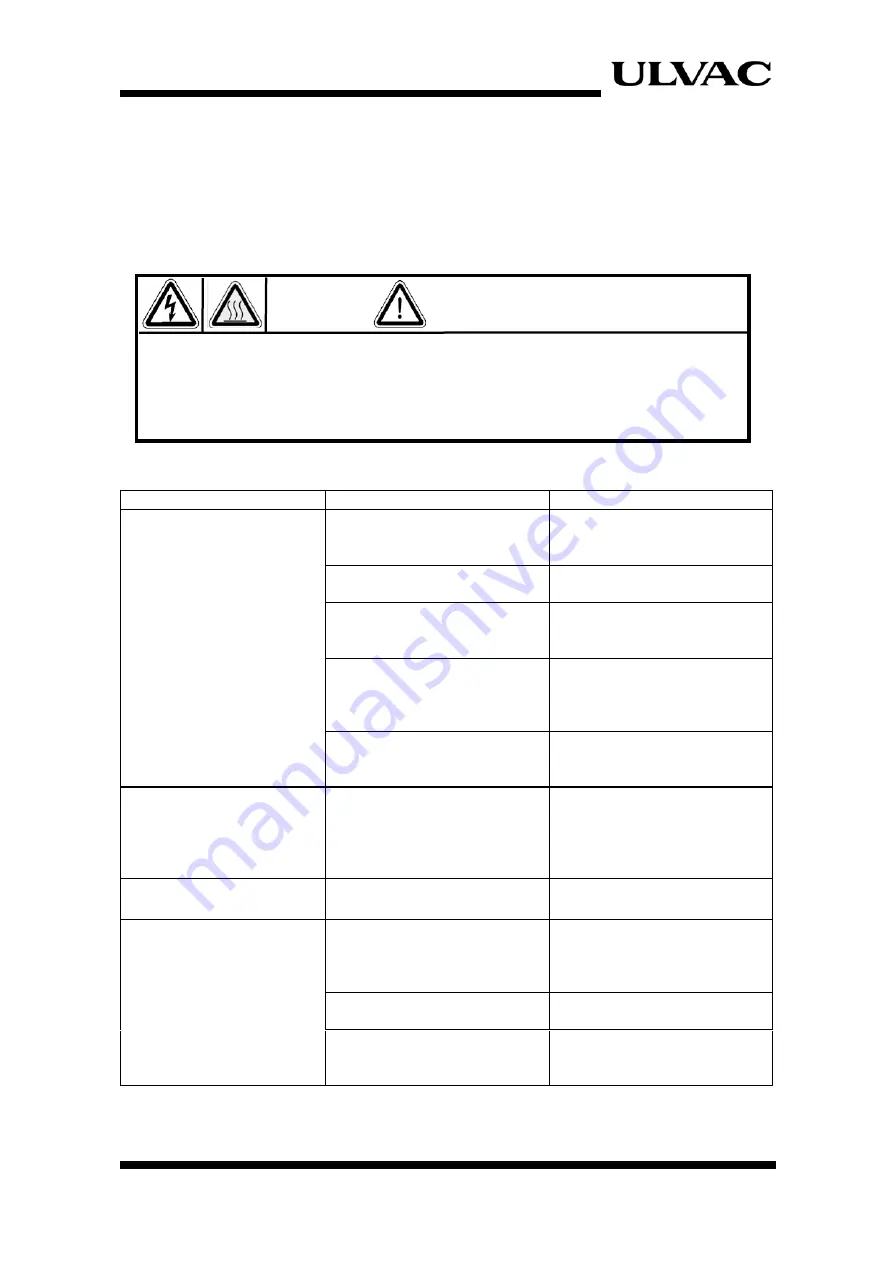

Ensure that main power is disconnected before inspecting the power source or

inside of the equipment. Some parts of the equipment may remain in high

temperature right after stopping operation. Use caution to avoid burn injury.

WARNING