13

4.2.15 Install the edge protection at the bottom of the opening.

Mount the drum on the side panel. Cut the strength member to 60 mm

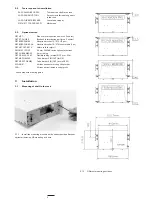

maximum. Attach the strength member and install as shown.

4.3

Back cable termination directly on the shelf

4.3.1

Cable terminations are suited for 2 cables, max. 3, cable

retention with tie-wraps. Loose tubes are fed through a flexible tube to

the shelf, the strength member is attached to the plate.

In case of IFC no flex tube is used (see point 4.3.10).

4.3.2

Kit contents

•

5 releasable tie-wraps

•

2 strength member conn screw

•

1 flexible tube

•

1 tube clip + lid

•

3 bolts & nuts

•

1 foam strip

•

2 tie-wraps

•

1 metal plate

4.3.3

Assemble the components onto the termination plate. The

picture shows cable coming from the left (seen from the back), for

cable coming from right the reverse assembly is required.

X = 80 mm.

4.3.4

Apply 1 layer of foam tape around the flex tube at

approximately 10 mm from the end. This foam tape must be positioned

underneath 1 of the tie-wraps (this tape prevents easy pull-out of the

flex tube).

X = 80 mm

4.3.5

Fasten the flex tube (before trays are inserted,or remove trays)

at the back of the metal hinge plate using 2 small tie-wraps and a third

tie-wrap to the platform. Assure that tie-wraps are well tensioned to

avoid slippage of the tube and cut the excess length of the tie-wraps.

Knobs of the tie-wraps must be positioned at the

front

of the metal

hinge plate.

4.3.6

Remove the cable jacket over approximately 2 m. Wait to strip

the loose tube to avoid fiber breakage. Cut the strength member to

length (L = max. 60 mm) and fasten the strength member connector

with the Allen key.

l

A

Loose tube cable