23

To inspect the discharge valves, proceed as follows:

1. Drain oil from the pump and remove the separator housing cover.

2. Unscrew the air/oil separator from the top of the valve deck cover.

3. Remove the capscrews from the valve deck cover and remove the cover.

4. The valve chamber will contain a quantity of oil. Drain the chamber by removing the pipe plug on the

closed head end of the cylinder. As an alternative, scoop the oil out of the valve cavity with a small

container. Remove cap screws in valve hold down plates and lift out valve plates with valves.

5. Inspect the valves by snapping the valve disk or lower valve spring away from the valve seat to check

for spring tension and mechanical defects. Inspect the sealing surfaces for dirt or other foreign material.

Check that the disk or lower valve spring has not warped (dish shape) as they must be flat for full

contact. If a more careful inspection is required, remove the cap screw(s) holding the valve together.

When reassembling the valve, replace valve components in exactly the same position as before.

6. Reinstall the valves in the pump.

NOTE

Caution must be used to insure no screws or objects enter the piston

chamber. It is recommended to replace the locking screws with new lock

screws when re-installing the valves and plates.

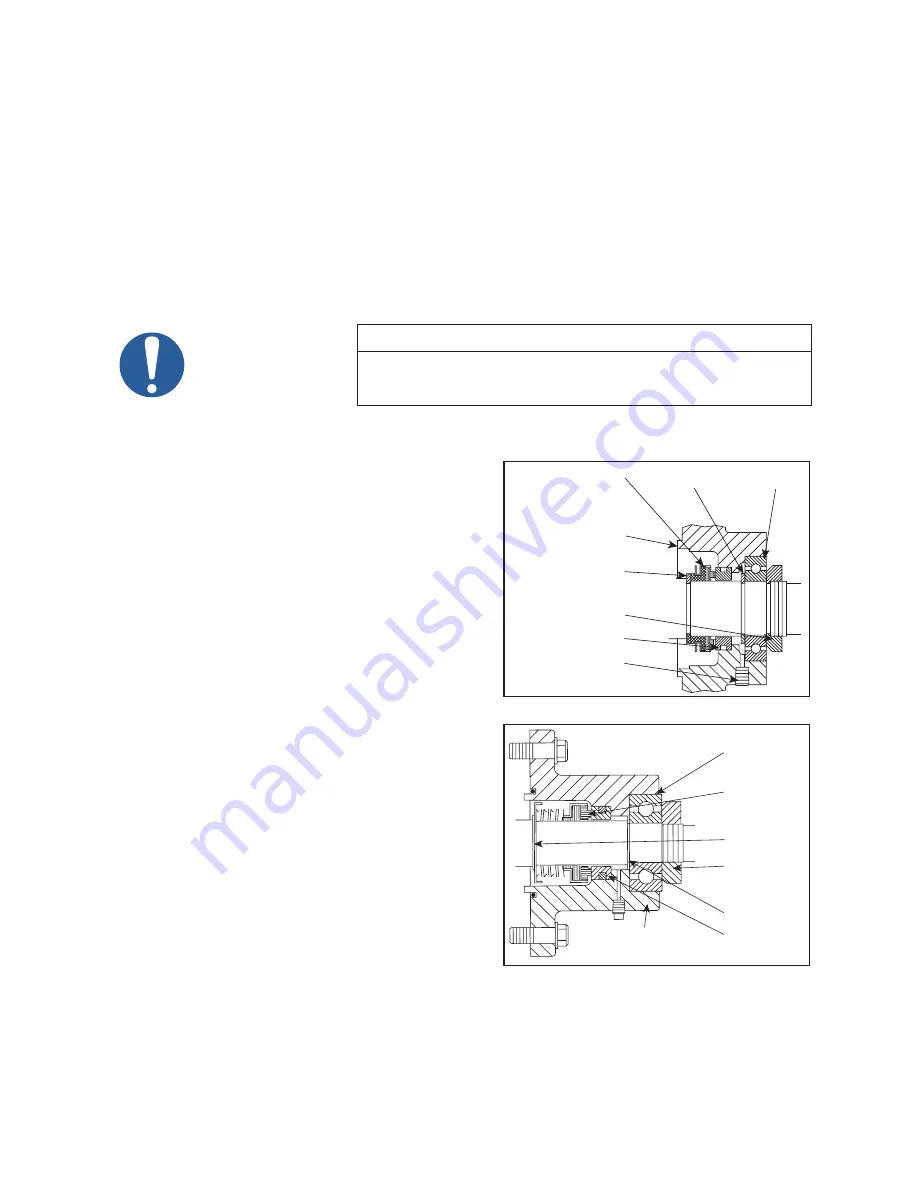

8.2 SHAFT SEAL ASSEMBLY

Under normal conditions, the shaft seal (See Figures 8

and 9) has a long trouble-free life. It may become worn

or scratched on the sealing face by dirty sealing oil which

also lubricates the shaft seal, or it may be damaged by

excessive heat due to poor lubrication.

If oil drips from the shaft seal and bearing housing, it is

an indication that the shaft seal should be inspected, and

replaced as necessary. The drain plug of the shaft seal

and bearing housing should be removed as long as oil is

leaking past the shaft seal. If oil which has leaked from

the shaft seal is allowed to drain through the bearing it

will wash the grease from the bearing and cause it to fail.

To inspect the seal:

1. Remove the belt guard and belts.

2. Remove the pump pulley and drive key from the

shaft.

3. Remove the shaft bearing and housing:

(a) Remove the outboard bearing retainer nut from

the shaft.

(b) Remove the capscrews holding the bearing

housing and remove it.

4. Inspect the face of the running surface for dirt,

scratches, or grooves, which might cause leaks into

the pump. A smooth shining carbon face indicates a

good seal. A crease across the sealing ring, a dent,

or scratch in the running face makes a direct leak

through the seal. Cracks or hardening of the rubber

parts indicate that they were exposed to excessive

operating temperatures and need replacement.

Figure 8 - KT-150 Shaft Seal & Bearing Housing

SHAFT SEAL AND

BEARING HOUSING

MECHANICAL

SHAFT SEAL

BEARING

BACK-UP RING

BALL

BEARING

SEAL

BACK-UP RING

MATING RING

LOCKNUT

DRAIN PLUG

Figure 9 - KT-300, KT-500, KT-850 Shaft Seal

& Bearing Housing

BALL BEARING

MATING RING

LOCKNUT

BEARING

BACK-UP RING

SHAFT SEAL

BEARING HOUSING

MECHANICAL

SHAFT SEAL

SHAFT SEAL

BACK-UP RING

Summary of Contents for KINNEY 850D

Page 29: ...29 NOTES ...

Page 35: ...35 NOTES ...